Light-emitting structure

A light-emitting structure and reflective structure technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as high temperature and affect quantum luminous efficiency, and achieve the effect of increasing heat dissipation area, improving luminous efficiency, and good light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

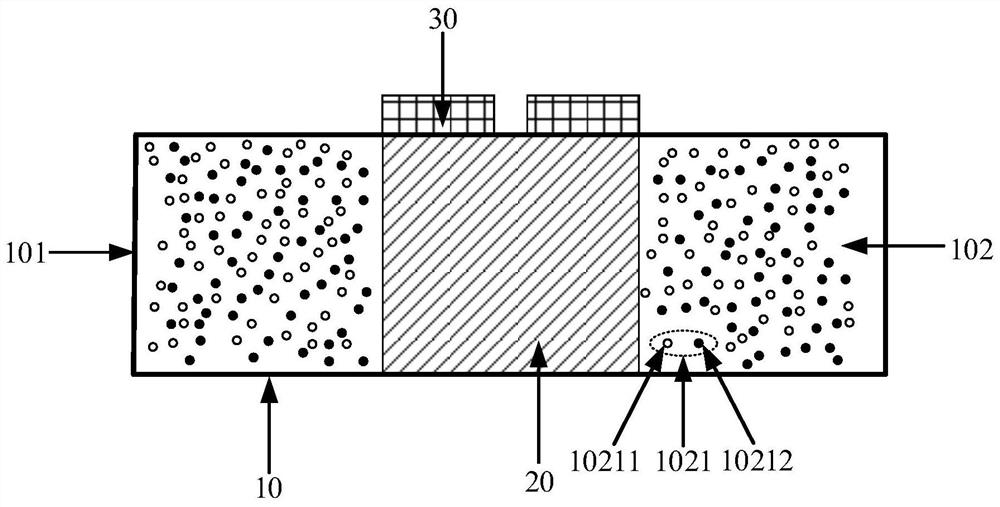

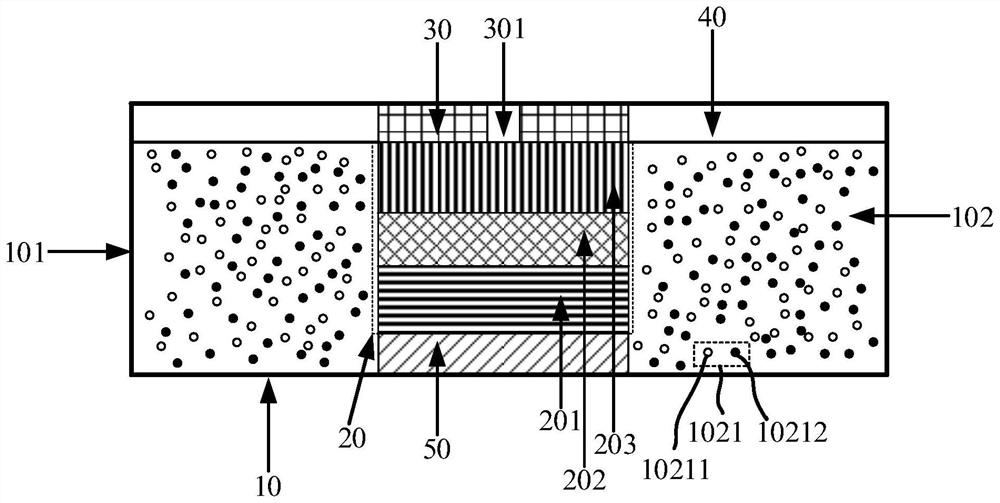

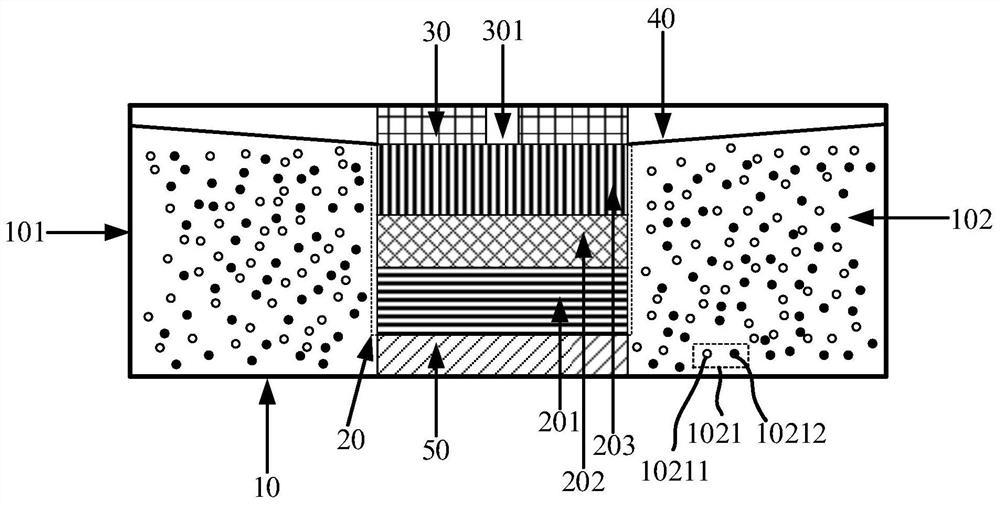

[0024] figure 1 is a schematic diagram of a light emitting structure provided by an embodiment of the present invention, refer to figure 1 , the light-emitting structure includes: a substrate 10, an LED chip 20 disposed on the surface of the substrate 10, and a reflective electrode 30 disposed on the side of the LED chip 20 away from the substrate 10; The structure 101 is arranged around the LED chip 20, and the light emission adjustment layer 102 is arranged around the side wall of the LED chip 20 and is located between the reflective structure 101 and the LED chip 20; On the one hand, the distance between the first side and the substrate 10 is equal to the distance between the surface of the LED chip 20 away from the substrate 10 and the substrate 10 ; the light emission adjustment layer 102 includes quantum dots 1021 .

[0025] Wherein, the substrate 10 may be a metal substrate or sapphire, and the substrate 10 is mainly used for heat dissipation. The LED chips 20 include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com