Piezoelectric converter

A piezoelectric conversion and piezoelectric ceramic technology, which is applied to inking devices, circuits, piezoelectric devices/electrostrictive devices, etc. Effect of improving ejection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

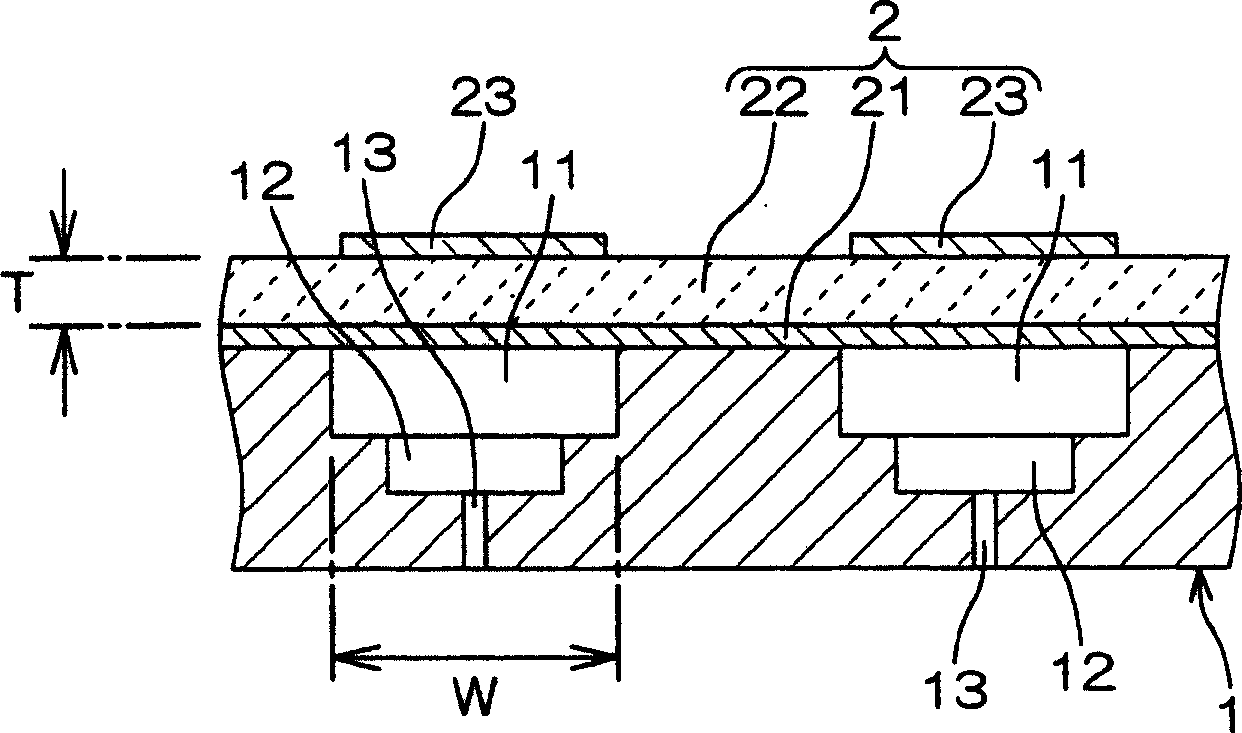

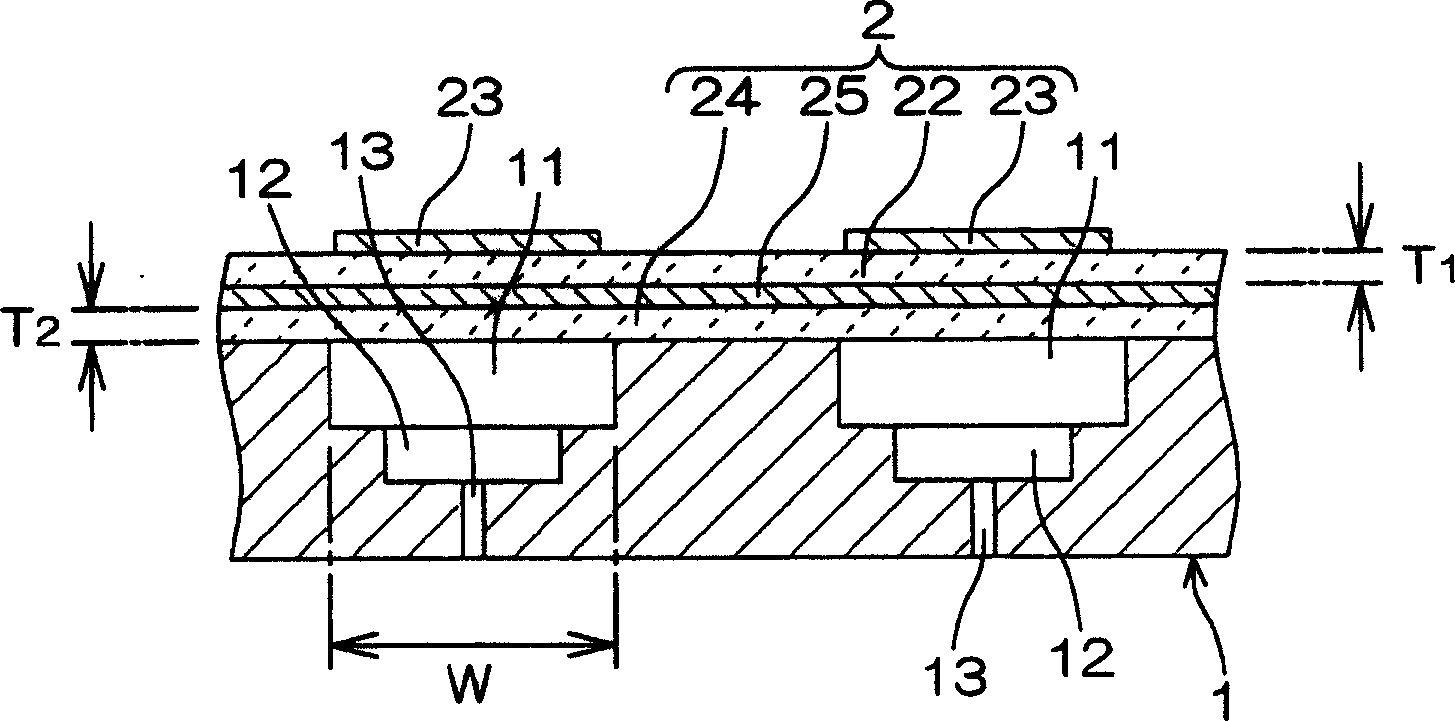

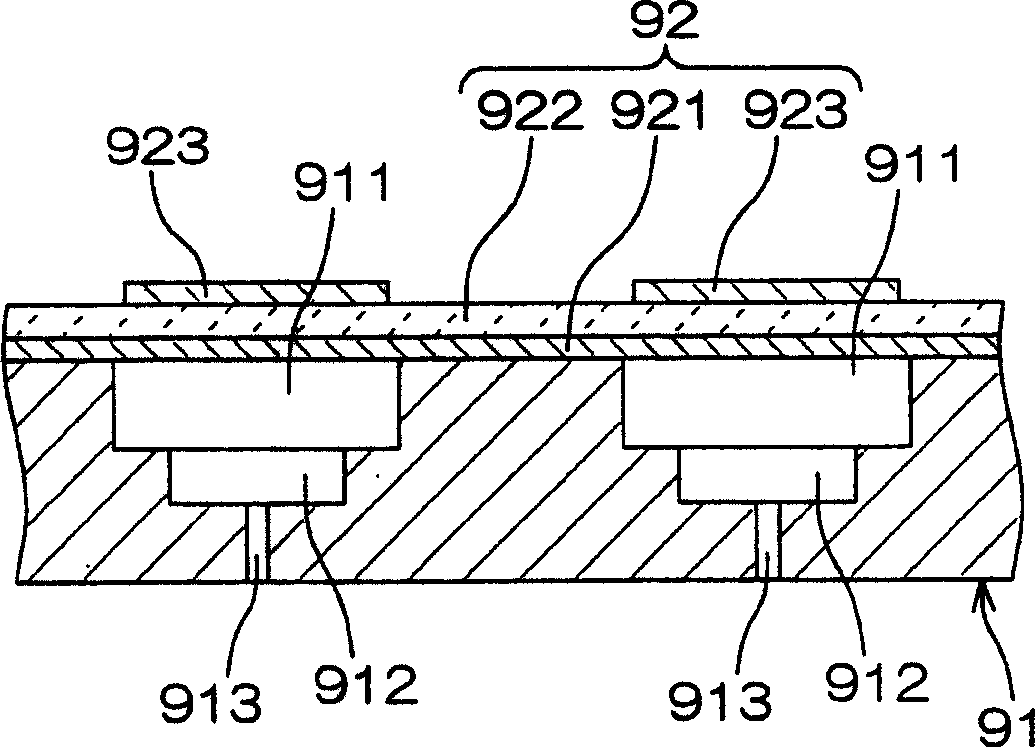

[0025] figure 1 It is a cross-sectional view showing an example of an embodiment of the piezoelectric conversion device of the present invention that can be ideally used as a piezoelectric inkjet head.

[0026] The piezoelectric transducing device in the illustration has a structure in which, on one side of a plate-shaped substrate 1 in which a plurality of cavities 11 for filling liquid are arranged along the surface direction, layers including a multi-layer structure and a structure covering the plurality of cavities are stacked. A conductive vibration plate 21 with a size of 11, a plate-shaped piezoelectric ceramic layer 22 having a size to cover a plurality of cavities 11, and a piezoelectric ceramic layer 22 having a size corresponding to each cavity 11 are separated corresponding to each cavity 11. The piezoelectric actuator 2 of a plurality of independent electrodes 23 .

[0027] The conductive vibrating plate 21 sandwiches the piezoelectric ceramic layer 22 together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com