A ink ribbon unit with supporting device and image printing equipment

A technology for supporting devices and printing equipment, which is applied in printing, inking devices, transfer materials, etc., can solve the problems of increased manufacturing cost and high cost, and achieve the effect of simplified structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

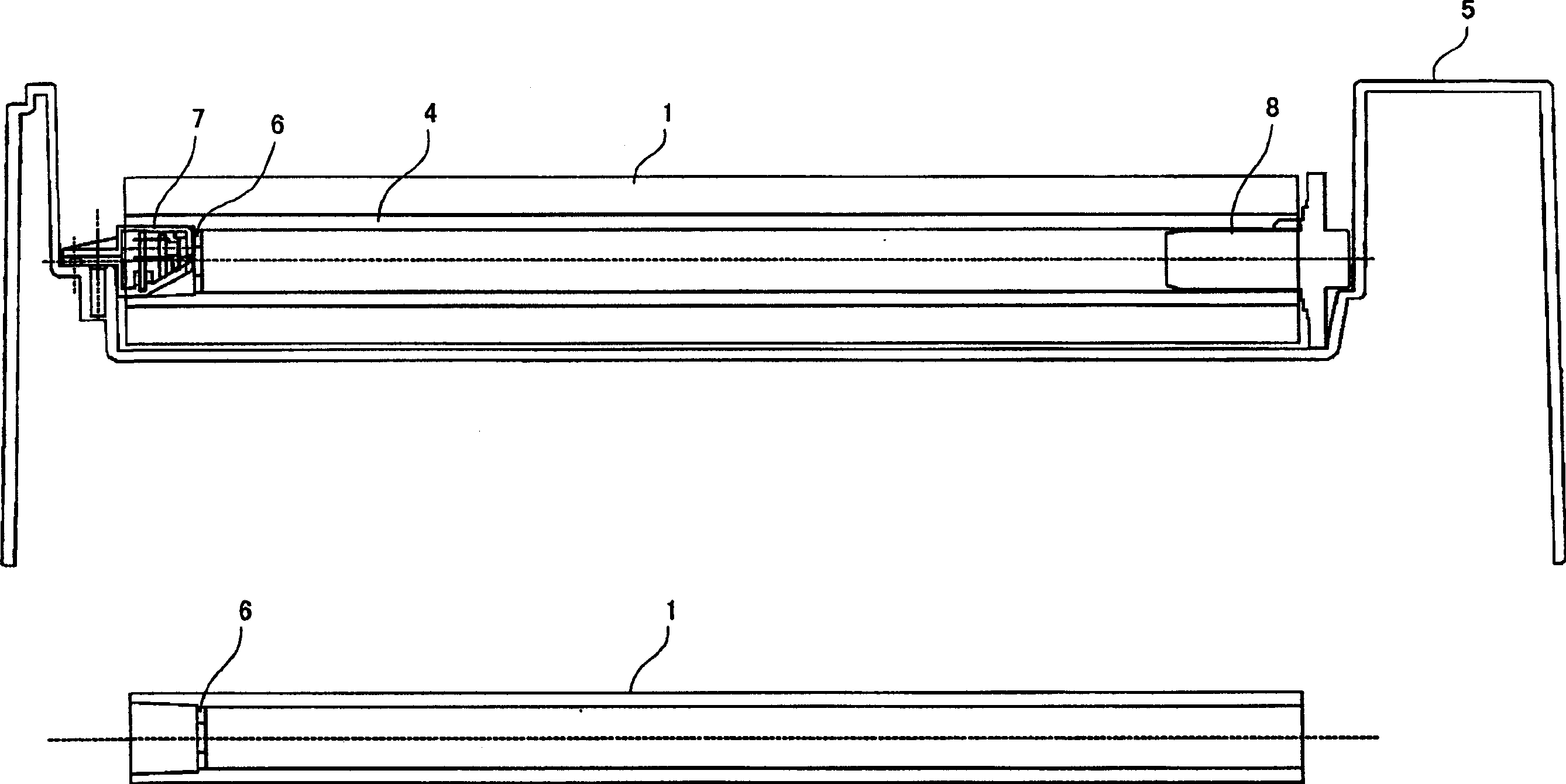

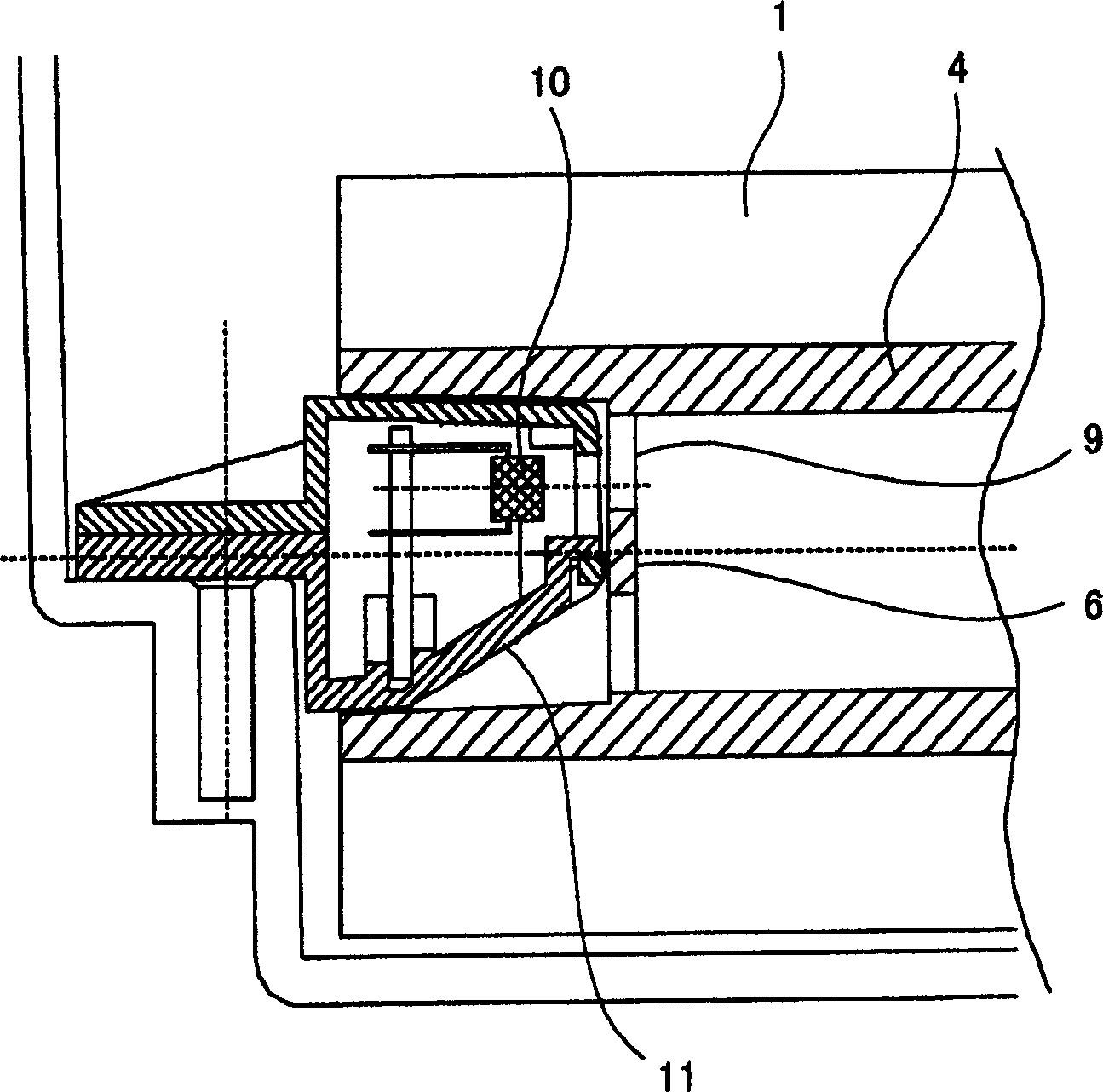

[0020] A tape support device and a structured ink ribbon unit for an image printing apparatus according to a preferred embodiment of the present invention will now be described in detail with reference to the accompanying drawings. figure 1 is a cross-sectional view of the ribbon support and structured ribbon unit, and figure 2 It is an enlarged cross-sectional view showing a part of the belt support device.

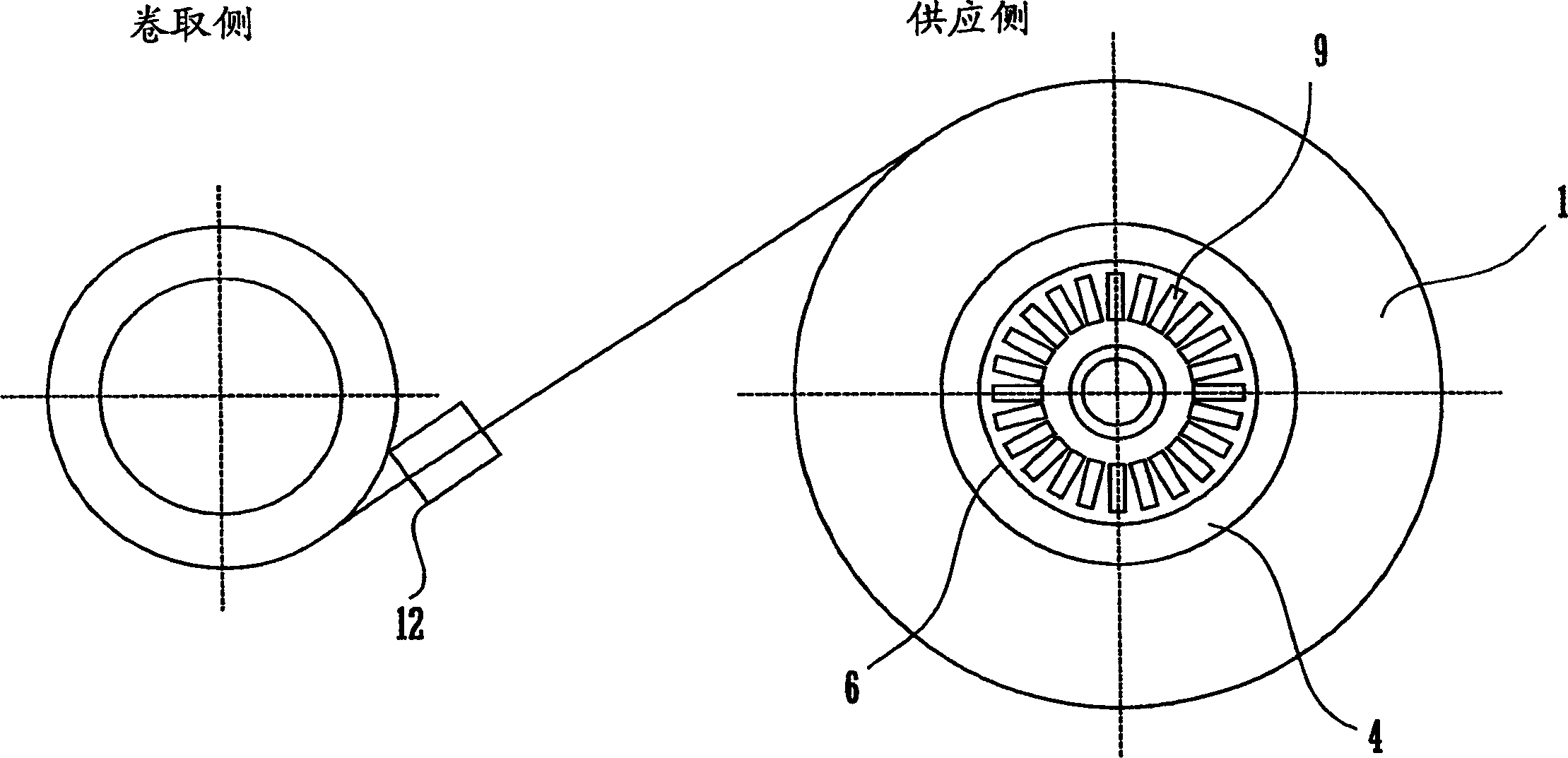

[0021] The structured ink ribbon unit includes a hollow ribbon core 4 and a rolled ink ribbon 1 wound in a cylindrical form around the core 4 . Inside the tape core 4 , at a certain distance from one end of the tape core 4 , a partition disc 6 is mounted. A large number of radially arranged narrow openings or slots 9 are formed in the separating disc 6 . On the outside of the partition disc 6, there is provided a core support member 11 mounted in the cylindrical hole of the tape core 4 and supporting the tape core 4, the tape core support member 11 incorporating a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com