Ball-planting device for making several tin balls stick to chip

A chip and ball-mounting technology, applied in electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as inability to guarantee solder balls, time-consuming, eye fatigue for maintenance personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

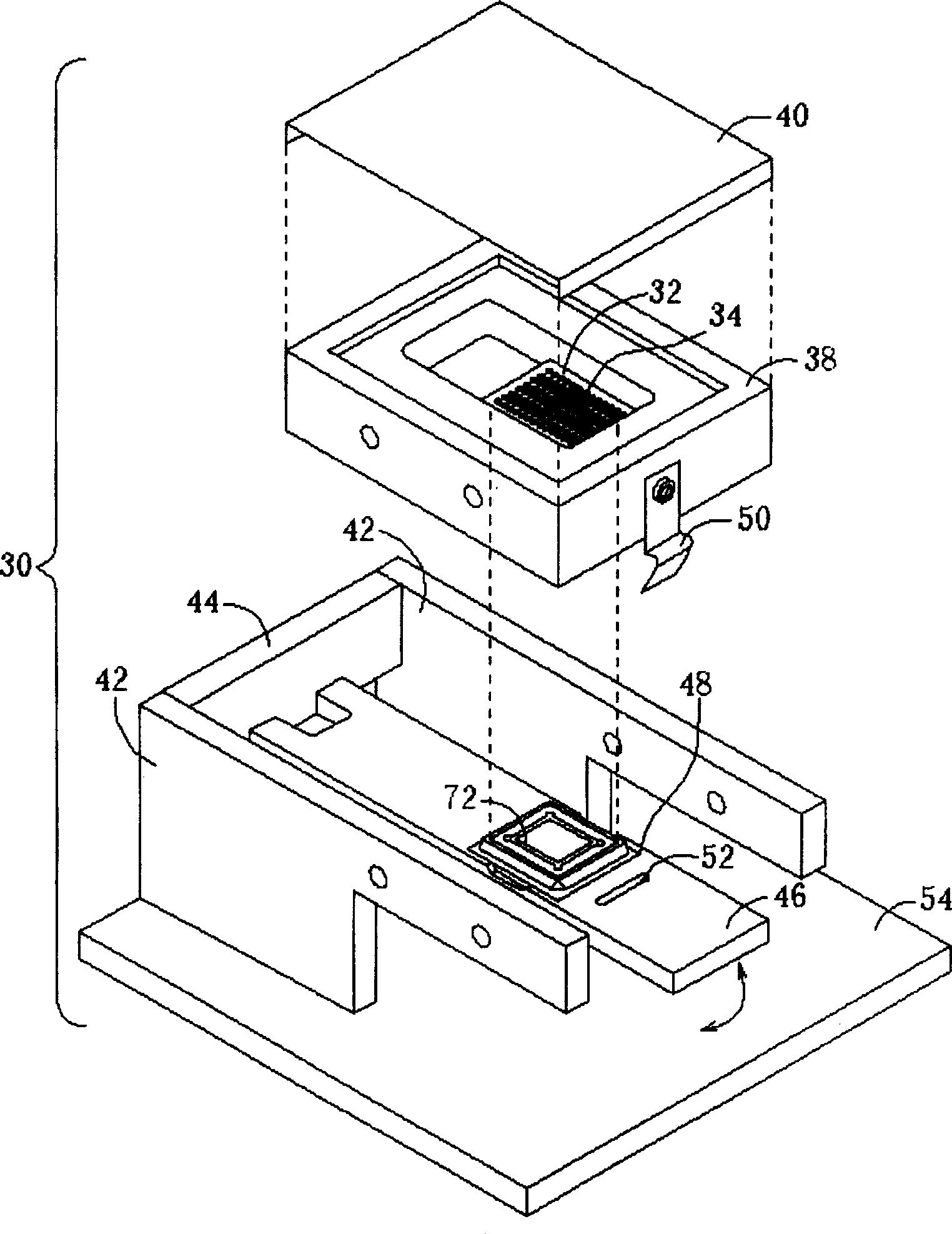

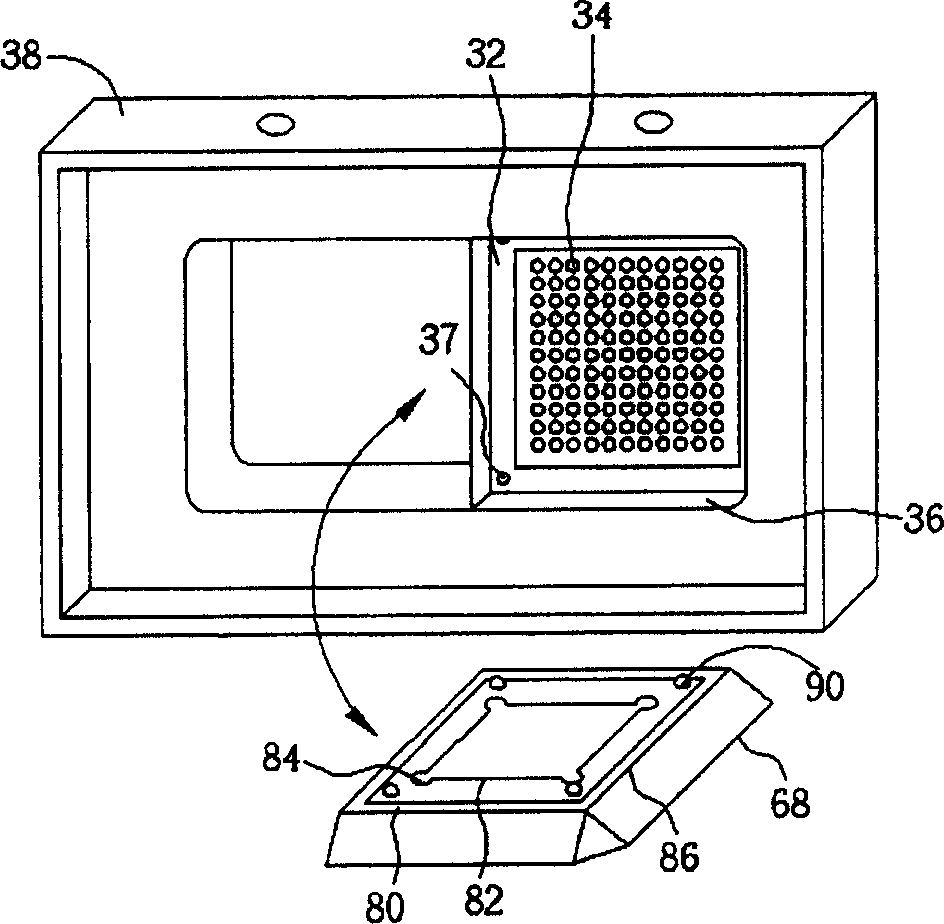

[0036] Please refer to figure 2 , figure 2 It is a schematic diagram of the table-top ball planting device 30 of the present invention. The ball planting device 30 is used to stick a plurality of solder balls with a diameter of 0.35 to 0.7 mm on a chip 72, and the chip 72 is coated with a thin layer of solder paste ( flux) and the like, which are used to adhere the solder balls implanted by the ball planting device 30 to the chip 72 . The ball planting device 30 includes a perforated plate 32 with a plurality of bead holes 34, each of which is used to accommodate a solder ball, and a locator 36 (shown in image 3 ), arranged under the perforated plate 32, used to fix the chip 72 under the perforated plate 32 to ensure that the positions of a plurality of cloth bead holes 34 on the perforated plate 32 can accurately correspond to a plurality of solder balls that should be implanted The positions on the chip 72 and a ball well 38 are used to load the plurality of solder ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com