Tyre mould

A mold and tire tread technology, applied in the field of tire manufacturing, can solve problems such as difficulty in maintaining the distribution of metal sheets, hindering the opening and closing movement of the mold, and flashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

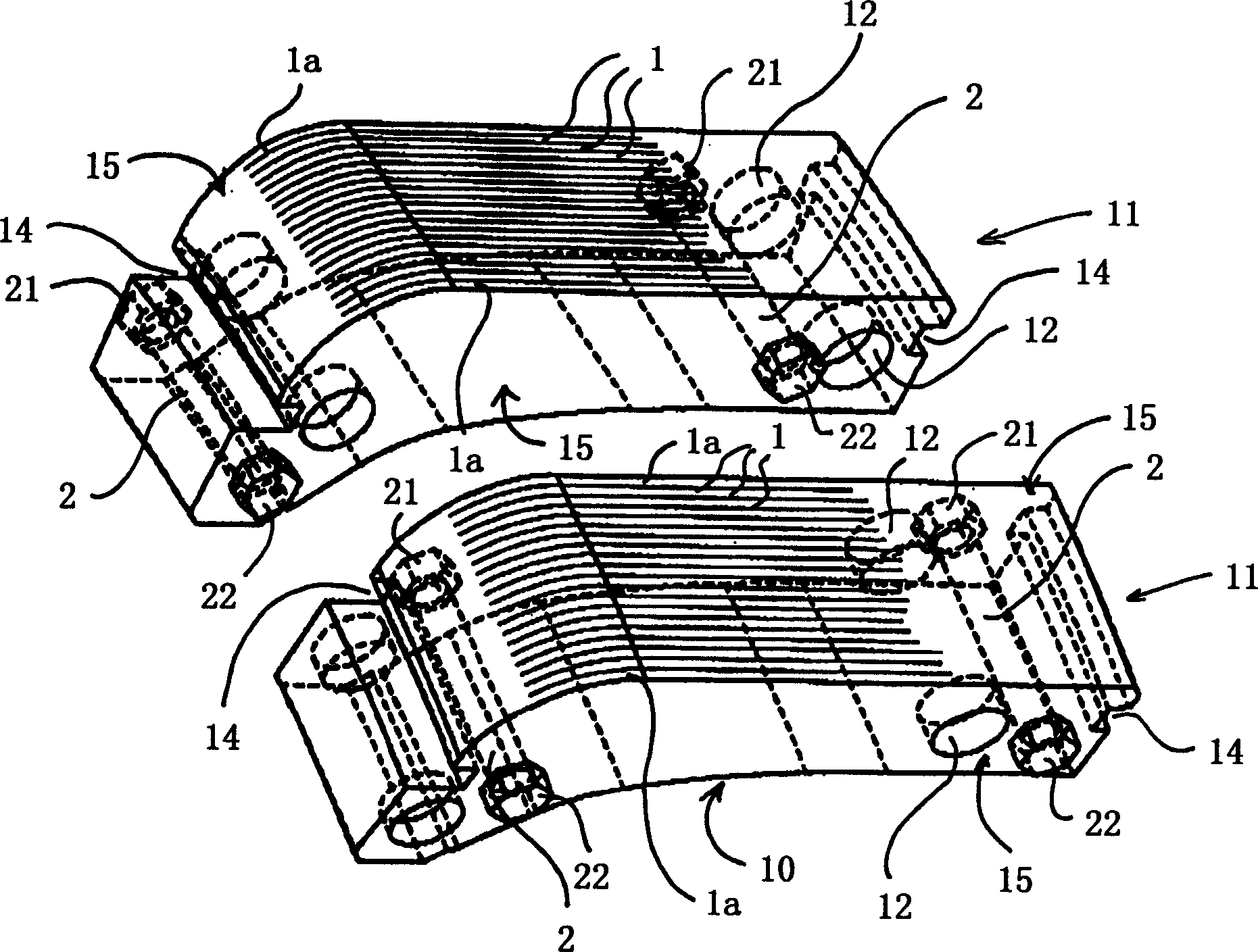

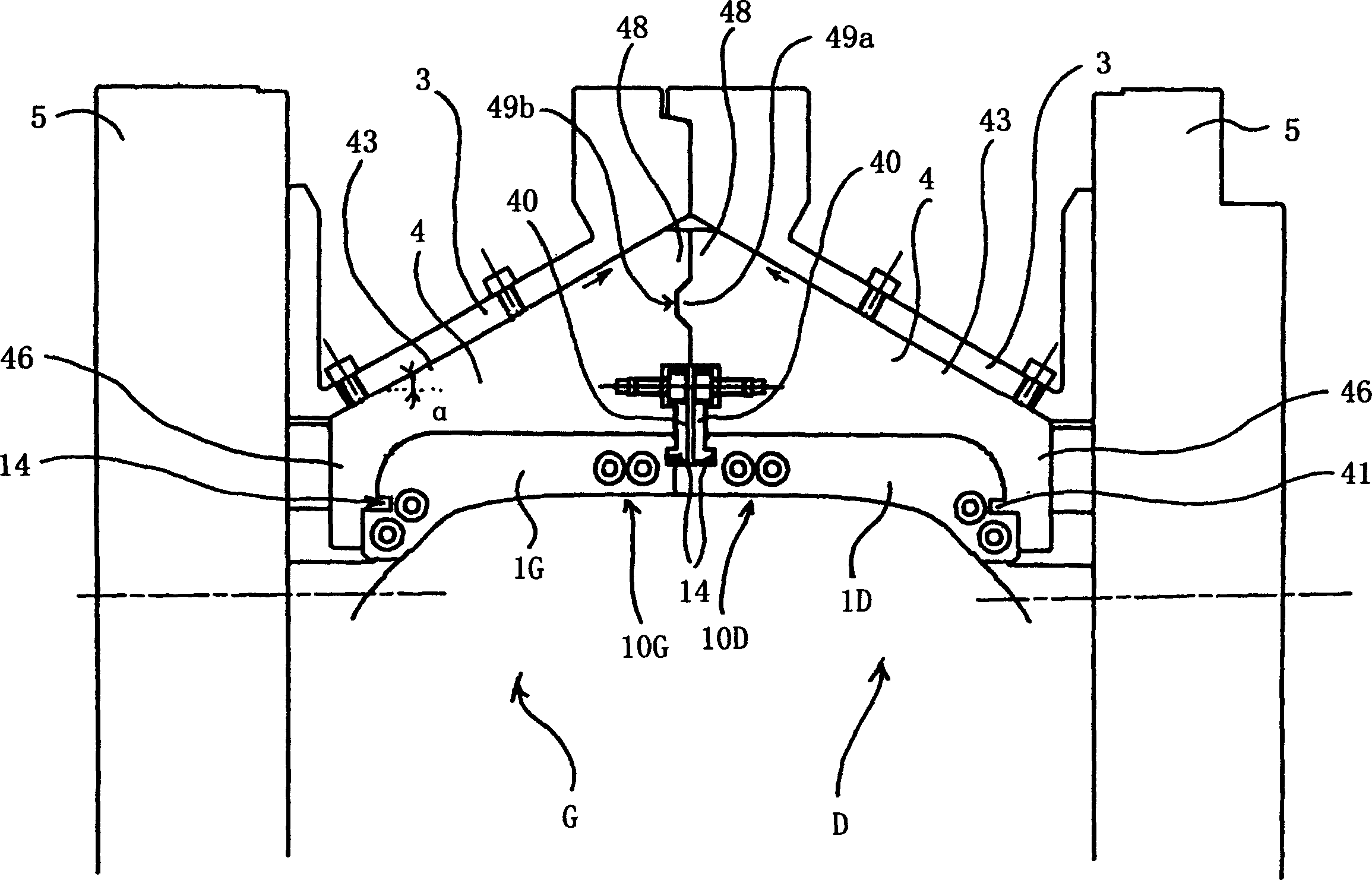

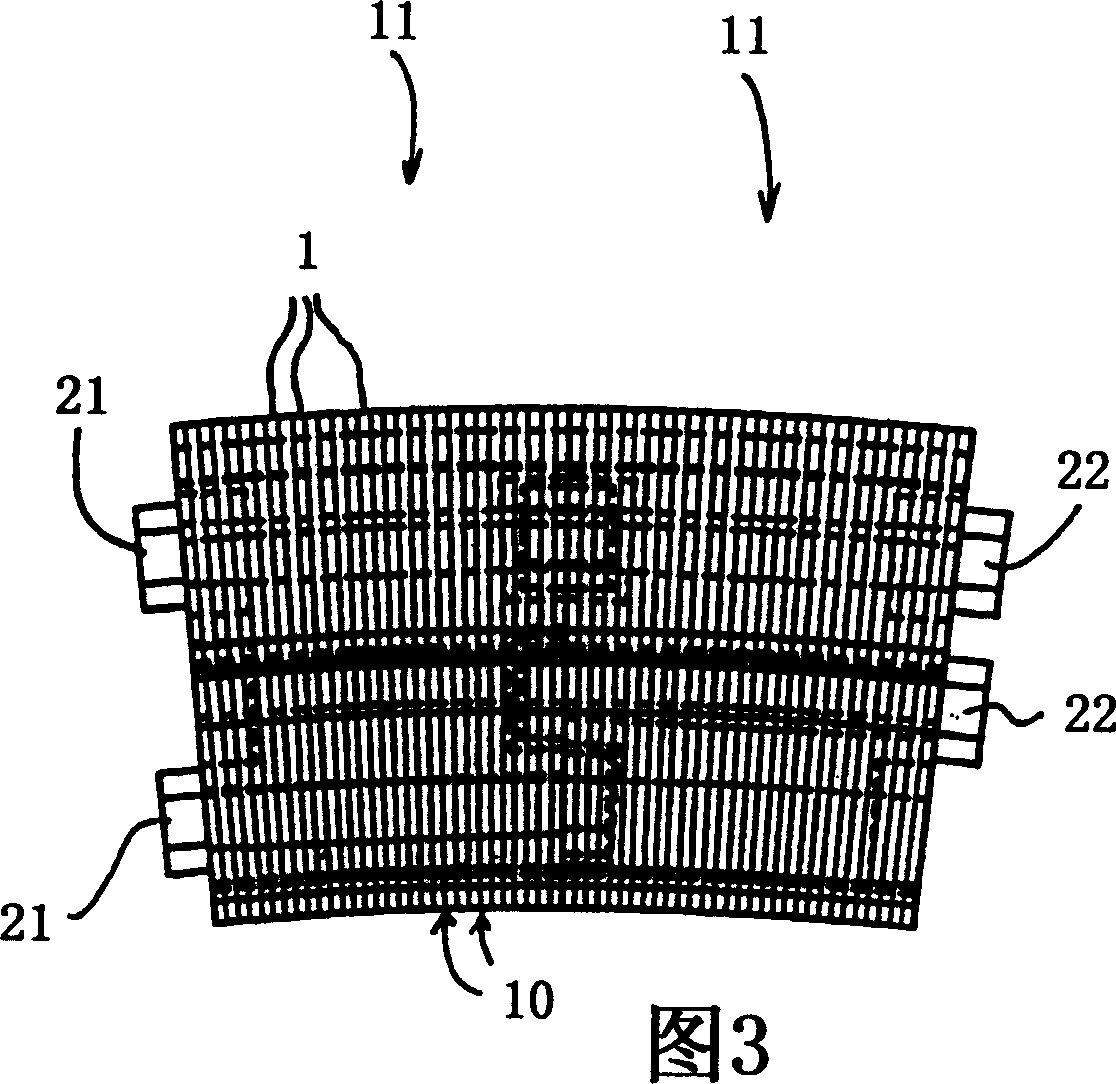

[0021] In the mold of this embodiment, the molding elements for molding the sheet-combined ring of the tread are metal sheets 1 adjacent to each other, with a thickness between 0.1 mm (preferably 0.5 mm) and 5 mm (see figure 2 ). Sheet composite rings consist of thousands of sheets of metal placed next to each other. This is a very advantageous method of making thin components with such mold characteristics. The thickness of the metal sheet corresponds to the resolution of the pattern determined by the mold. For example thin layers of steel may be used; they are preferably cut perpendicular to the plane of the curve defined by the tread pattern to be produced. Since the steel sheets are always cut perpendicularly, some surfaces of the tread pattern look like the steps of a staircase, which is the appearance characteristic of this technology. The sides of the metal sheets are preferably non-parallel to each other so that when they are put together they naturally fan out and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com