Back light module

A technology of backlight components and light guide plates, applied in optics, nonlinear optics, instruments, etc., can solve problems such as poor structural rigidity and difficulty in designing thin models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

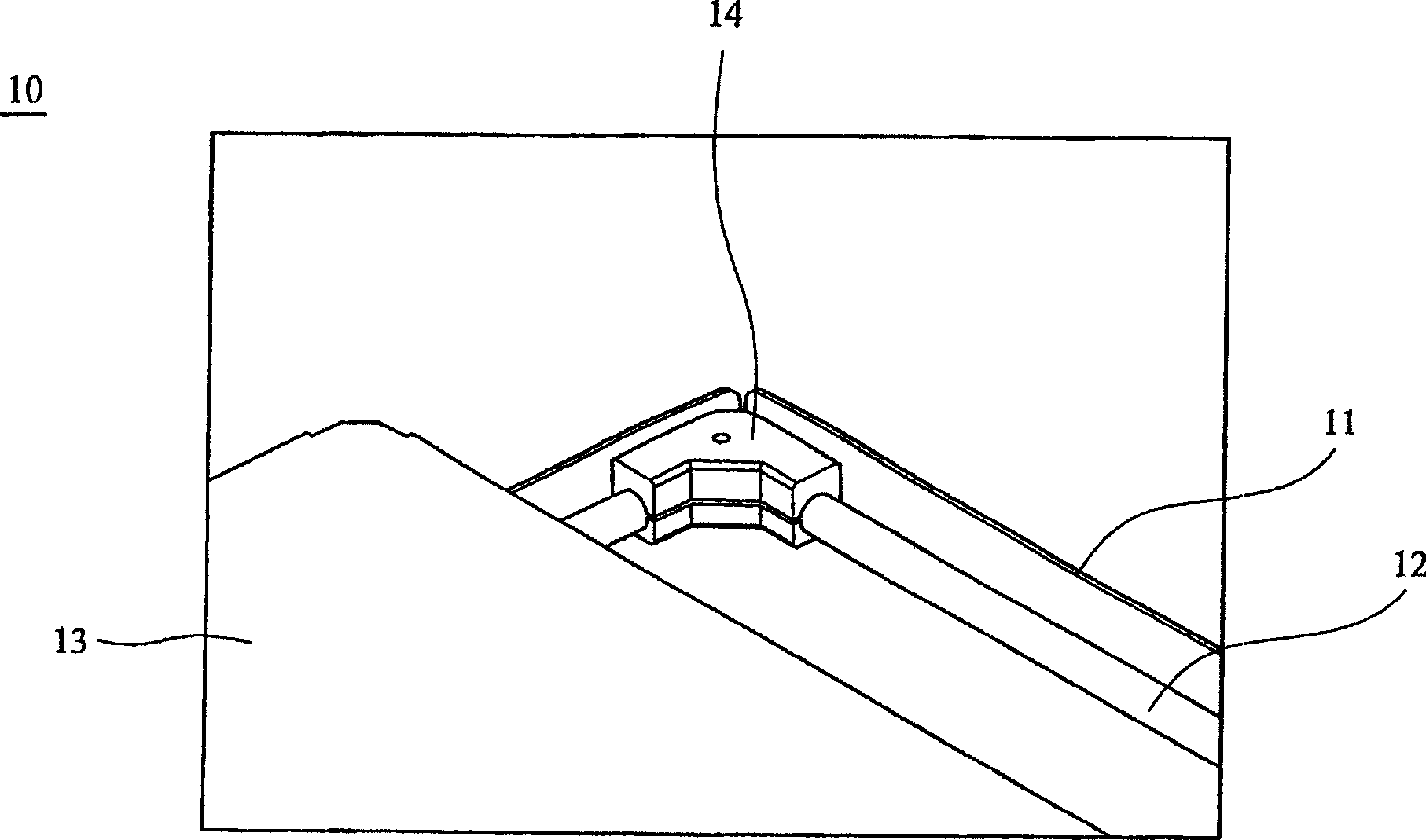

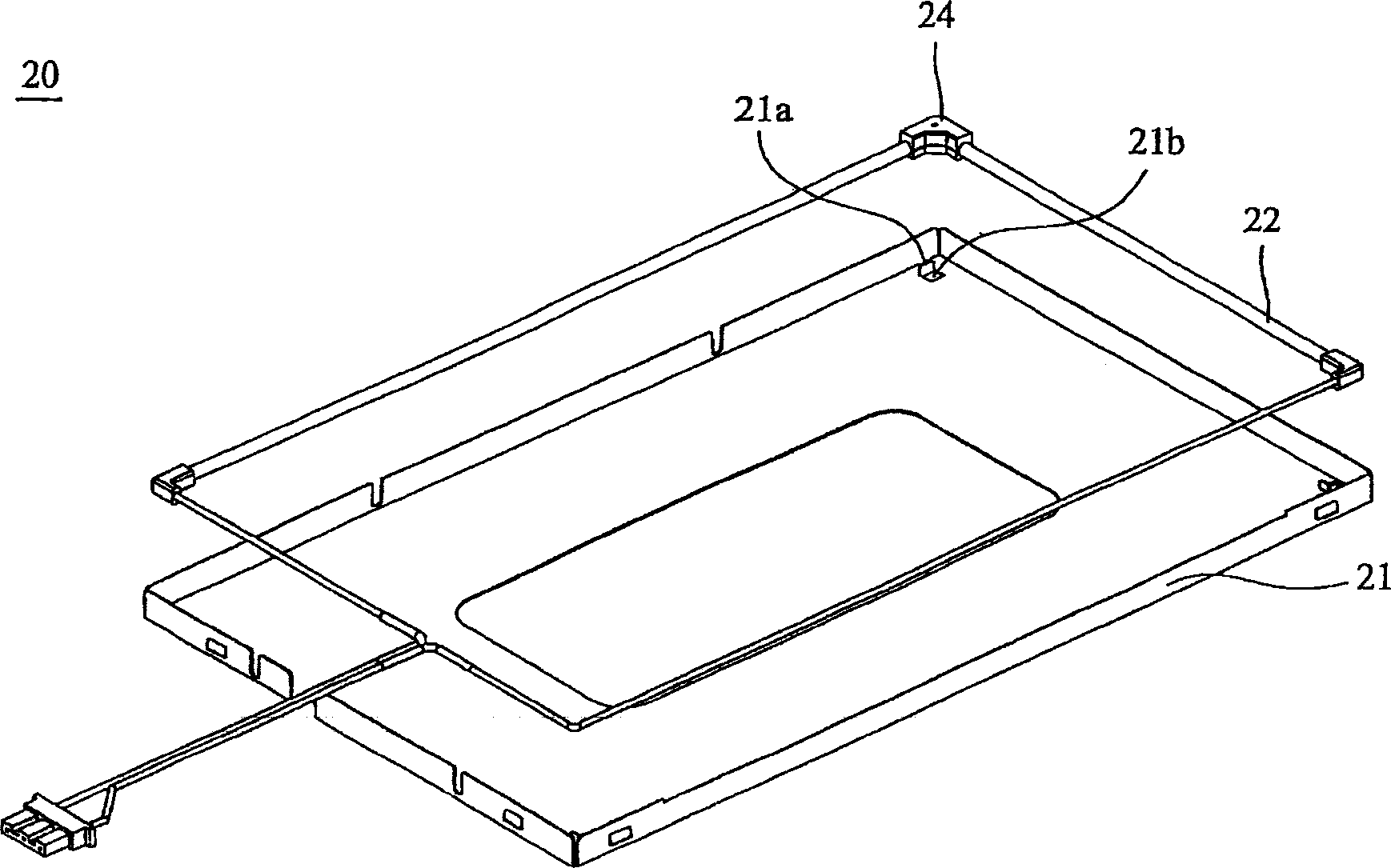

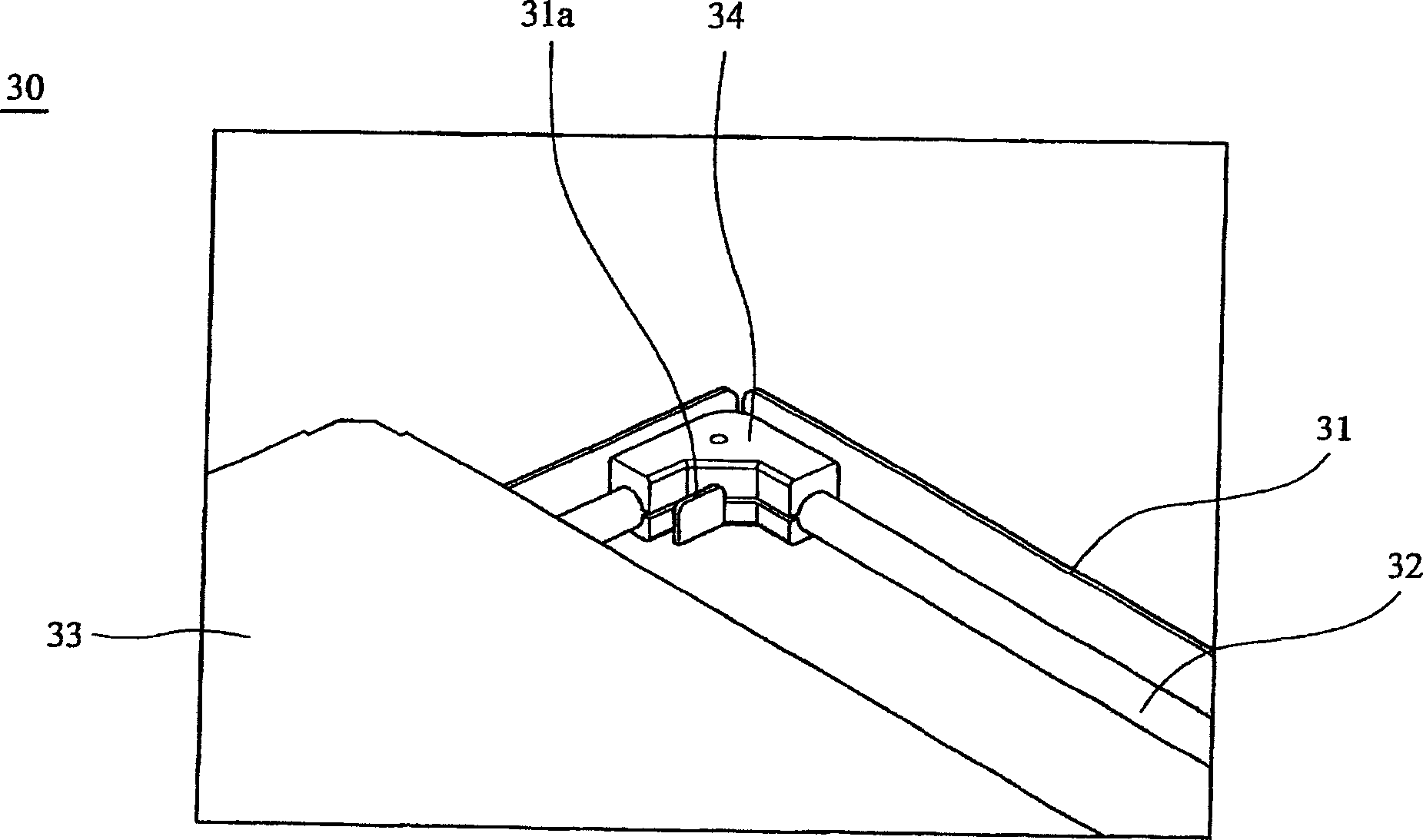

[0053] refer to Figure 4a , the backlight assembly 100 of the present invention includes: a bottom case 110, a frame 120, a light guide plate 130, a lamp tube 140, two fixing members 150, and a reflector 160. It should be understood that there are still Since other components are not directly related to the present invention, their descriptions are omitted here.

[0054] The bottom case 110 is made of metal, such as iron, and is used to carry other components. The frame 120 is made of plastic, which is disposed on the bottom case 110 and forms a blocking wall 121 at a corner.

[0055] The light guide plate 130 is disposed on the bottom case 110 and is located in the frame 120. The light guide plate 130 has four sides 130a, 130b, wherein the side 130a is in contact with the frame 120, and the side 130b is in close contact with the lamp tube 140, as Figure 4b Shown; Also, the shape of the retaining wall 121 of the frame 120 corresponds to the shape of the corner 130c between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com