Air flow dryer for granular material

An air-flow dryer and granular technology, which is used in dryers, tobacco drying, drying of solid materials, etc., can solve the problems of uneven drying of cut tobacco, easy accumulation and breakage of cut tobacco, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

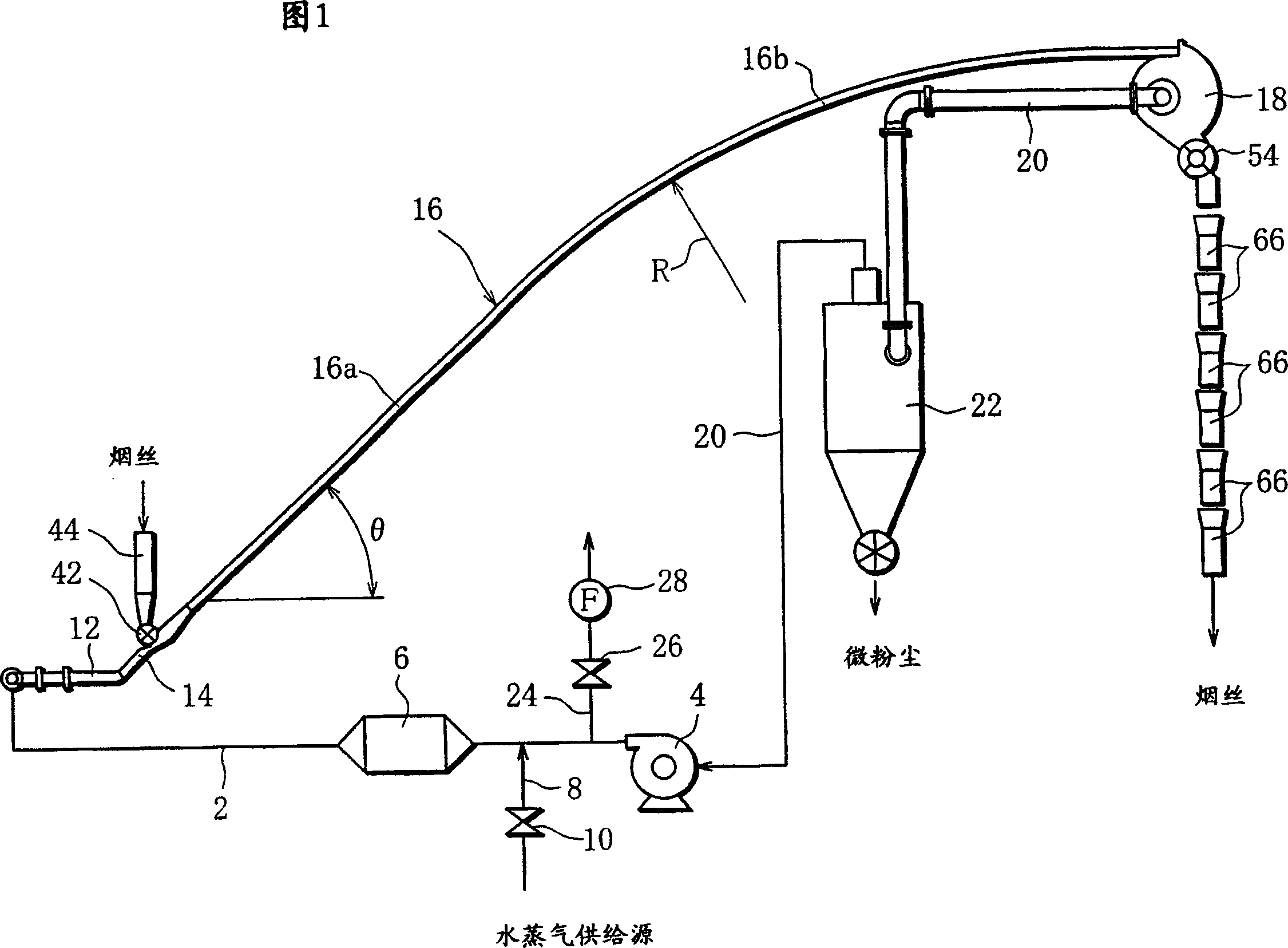

[0037] Fig. 1 schematically shows an airflow dryer used for drying treatment of shredded tobacco of pellets.

[0038] The gas dryer has a gas flow path 2, and a circulation blower 4 and a heater 6 are installed in this order in the gas flow path 2. The circulation blower 4 sends gas such as air to the heater 6, and the heater 6 heats the gas to a predetermined temperature, specifically to 160°C to 300°C, preferably to 180°C to 260°C.

[0039] A steam supply pipe 8 extends from a portion of the gas flow path 2 between the circulation blower 4 and the heater 6, and the steam supply pipe 8 is connected to a steam supply source. A steam supply valve 10 is inserted in the steam supply pipe 8 . When the steam supply valve 10 is opened, steam is supplied from the steam supply source to the gas in the gas flow path 2 through the steam supply pipe 8 , thereby generating a dry gas flow containing superheated steam in the gas flow path 2 . Here, the temperature of the dry air flow is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com