Bored under-reamed filling pile and fabricating method therefor

The technology of a bottom-expanding cast-in-place pile and its manufacturing method is applied in the field of drilled-bottom-expanding cast-in-situ pile and its manufacture, which can solve the problems of poor uplift bearing capacity, troublesome construction, long pile body, etc., and achieve the purpose of increasing the bearing area of pile ends, The effect of simple construction and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

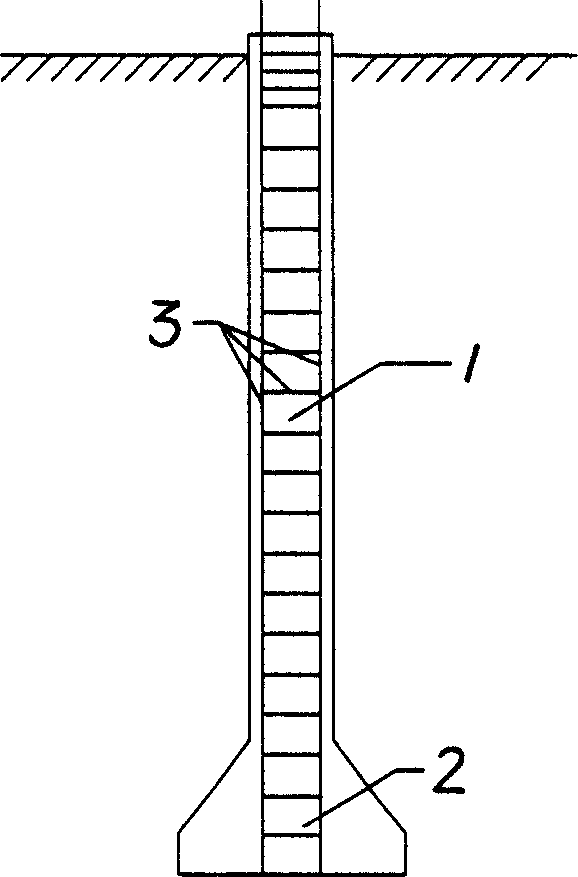

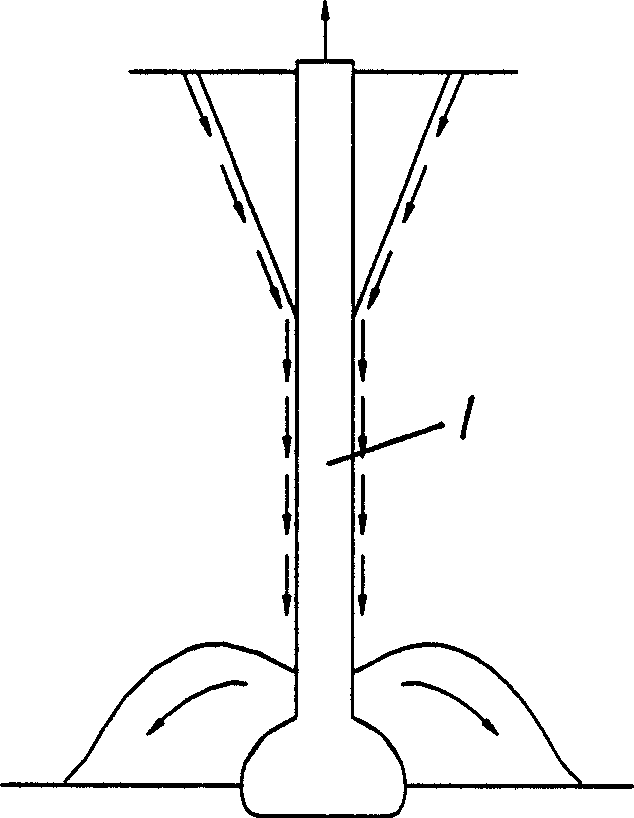

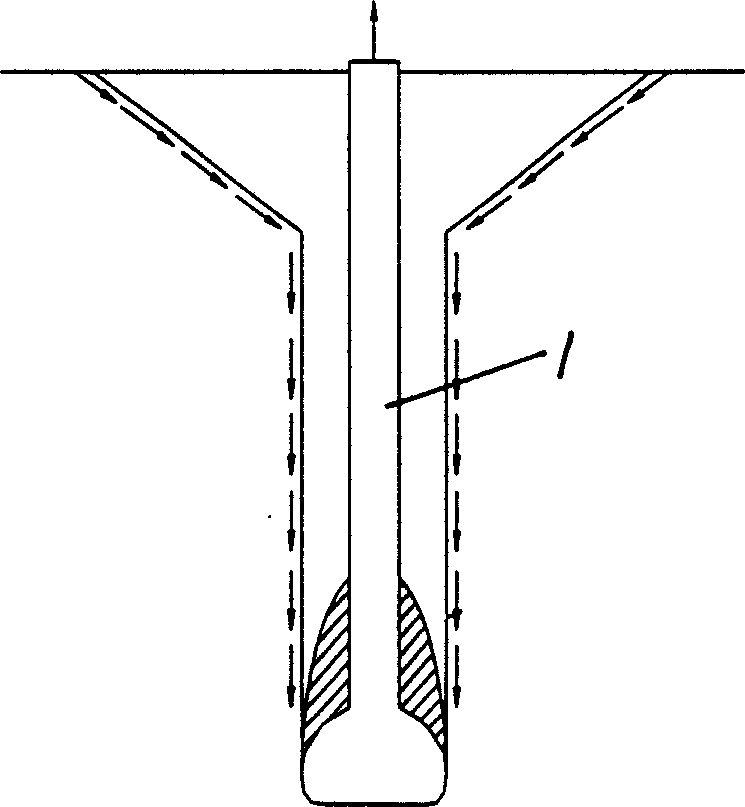

[0015] The present invention mainly comprises pile body 1, is characterized in that: described cast-in-place pile has an expanding head 2 at the bottom of pile body 1; The expanding head is concrete, its section is isosceles trapezoidal or conical, the inclination angle is greater than 30 degrees, the expanding head is 1.5-2.5 times of the pile diameter, and the whole pile is 30-70 meters long. A method for making cast-in-situ bored piles, characterized in that: the method for making cast-in-place piles includes the following steps: a, measuring and setting out, and fixing pile positions; b, laying casings, and putting a drilling rig in place; c, correcting The level of the grinding disc of the drilling rig and the verticality of the drill pipe; d, the hole is formed by positive circulation, and the drill bit is used to drill to the bottom of the hole, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com