Method and apparatus for measuring fatigue strength of zipper

A fatigue strength, zipper technology, applied in the direction of testing wear resistance, can solve the problem of fatigue strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

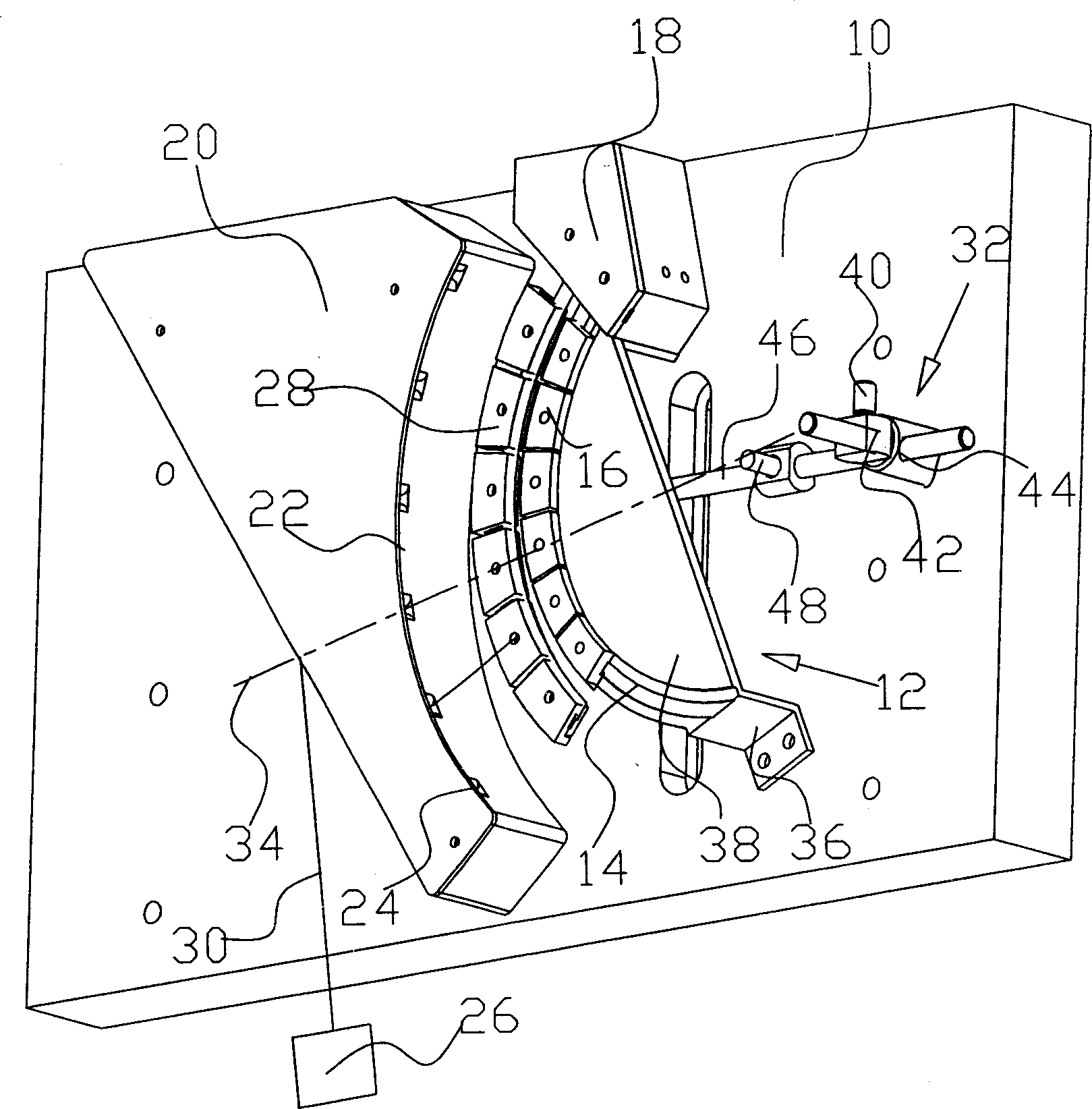

[0017] A method for measuring the fatigue strength of a zipper. The zipper includes a first tape with a zipper tooth row, a second tape and a slider; the first tape is fixed on the device in an arc, and the second tape passes through the The equipment is subjected to a predetermined tension; the upper ends of the first tape and the second tape are fixed on the equipment; the equipment drives the zipper head to reciprocate, so as to measure the fatigue strength and service life of the zipper.

[0018] Depending on the type of zipper, the reciprocating stroke of the zipper head, the clamping width of the first and second spring clips, the distance between the first spring clip and the second spring clip, and the weight of the weight can be adjusted separately.

[0019] The equipment drives the zipper head to reciprocate at a constant speed, 30 reciprocating movements per minute, and records the time and times of reciprocating movements, so as to measure the fatigue strength and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com