Inkjet printhead having thermal bend actuator heating element electrically isolated from nozzle chamber ink

一种喷墨打印头、喷嘴腔的技术,应用在电气元件、电固体器件、半导体器件等方向,能够解决突变失效等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

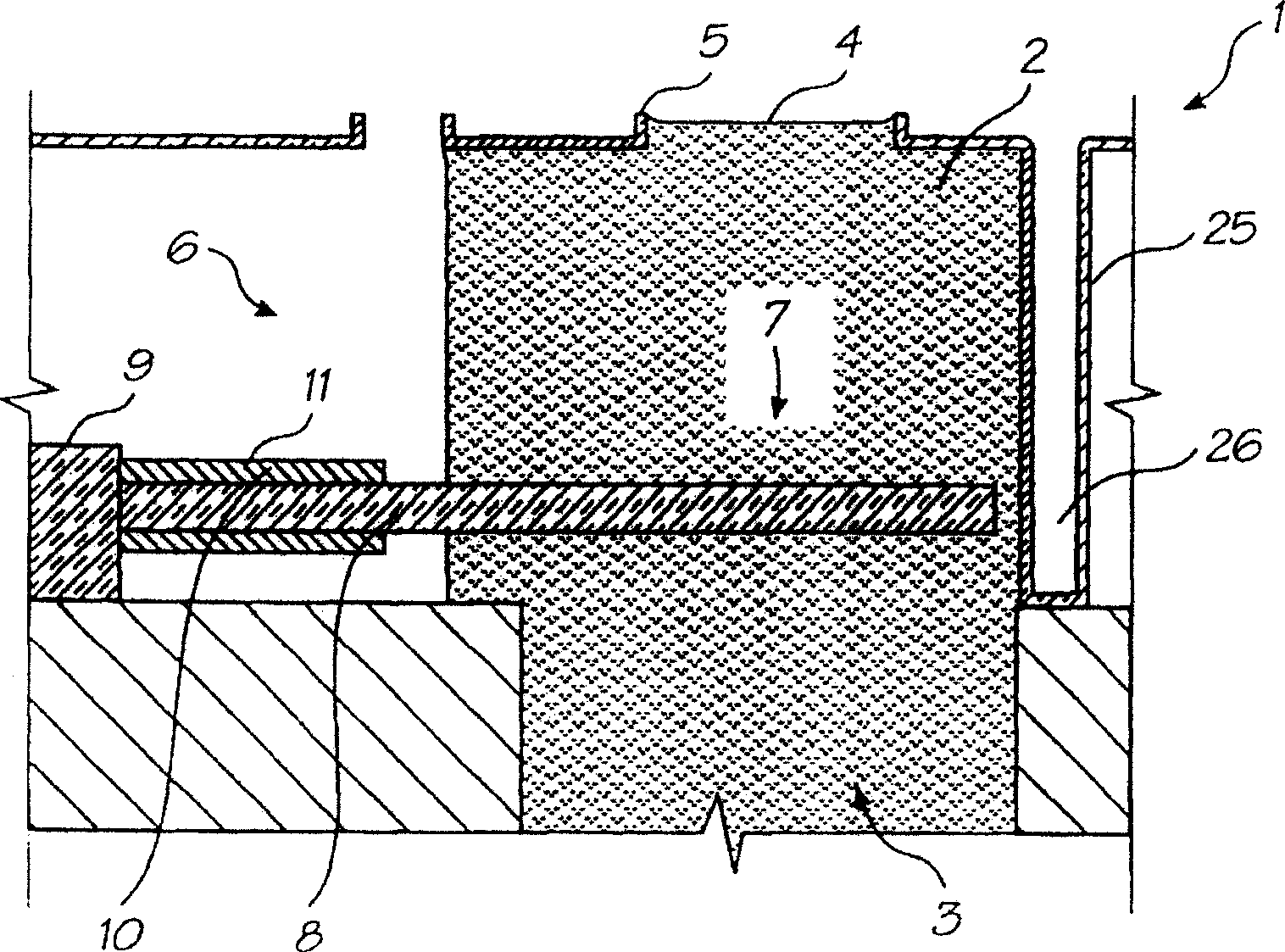

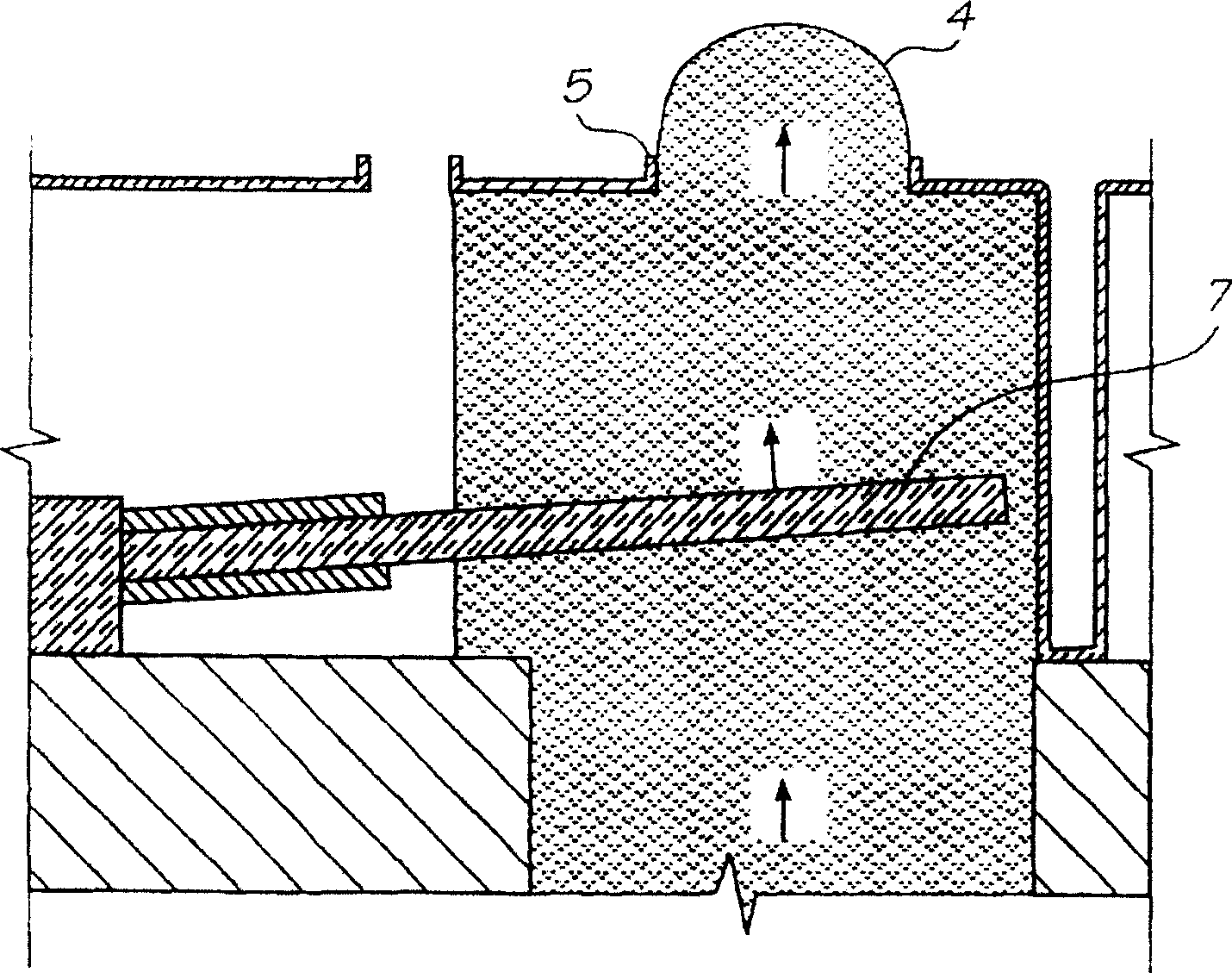

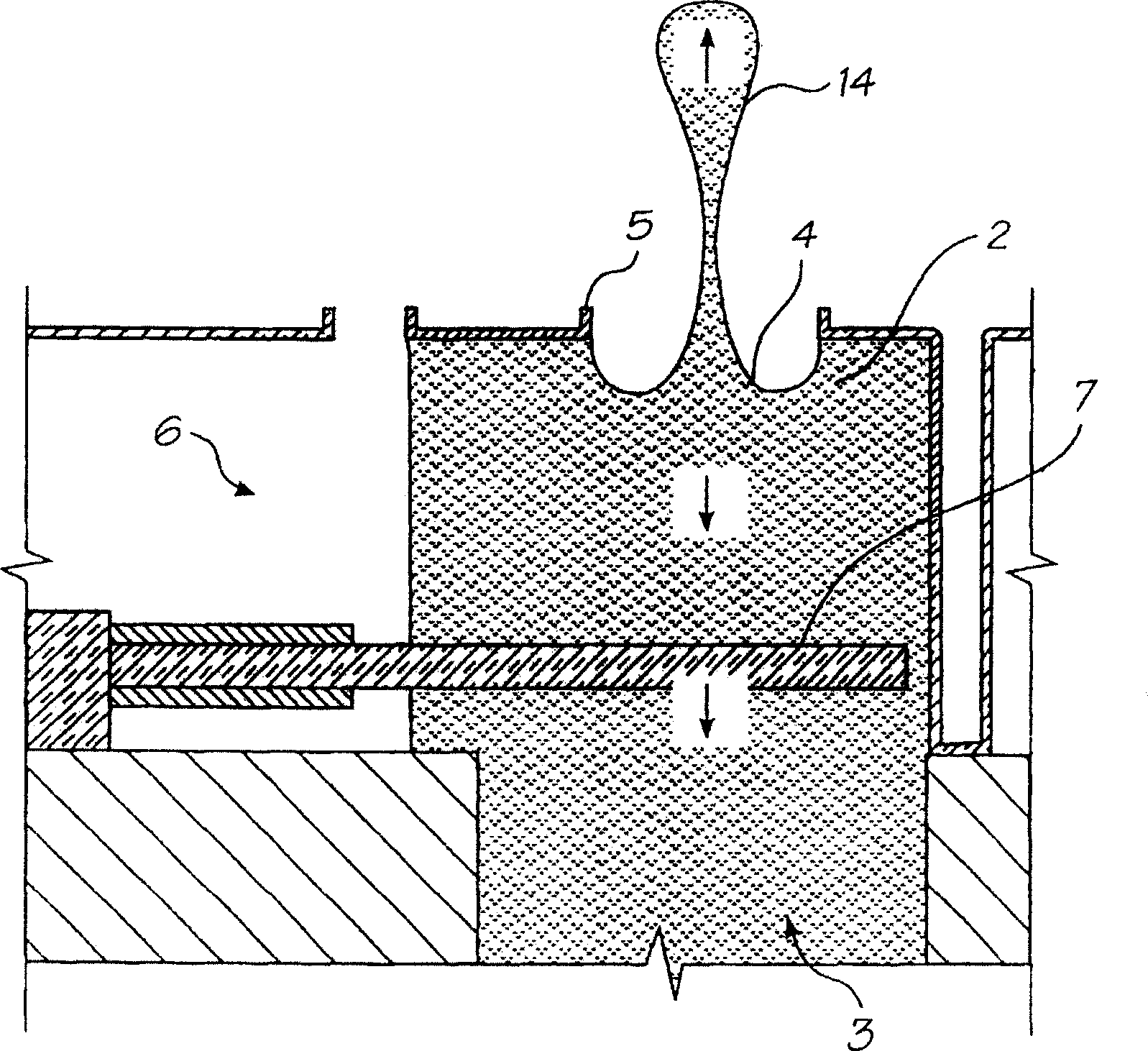

[0140] The preferred embodiment is a 1600 dpi modular single-chip printhead suitable for use in various pagewidth printers and print-on-demand camera systems. The printhead is fabricated using microelectromechanical systems (MEMS) technology, which refers to mechanical systems built on the micron scale, typically using techniques developed for the manufacture of integrated circuits.

[0141] Since a 1600dpi A4 photo-quality page-wide printer requires more than 50,000 nozzles, integrating the driver circuitry on the same chip as the printhead is key to achieving low cost.

[0142] The number of wires that integration allows from the outside world to the printhead is reduced from about 50,000 to about 100. To provide the drive circuitry, the preferred embodiment integrates CMOS logic and drive transistors on the same wafer as the MEMS nozzle. MEMS offers several major advantages over other manufacturing technologies:

[0143] Mechanisms can be constructed at micron-scale dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com