Shock absorbing steering column unit for vehicle

A steering column and impact absorption technology, which is applied to the steering control, steering column, steering control and other directions installed on the car, can solve the problem of short matching length and achieve the effect of smooth telescopic adjustment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

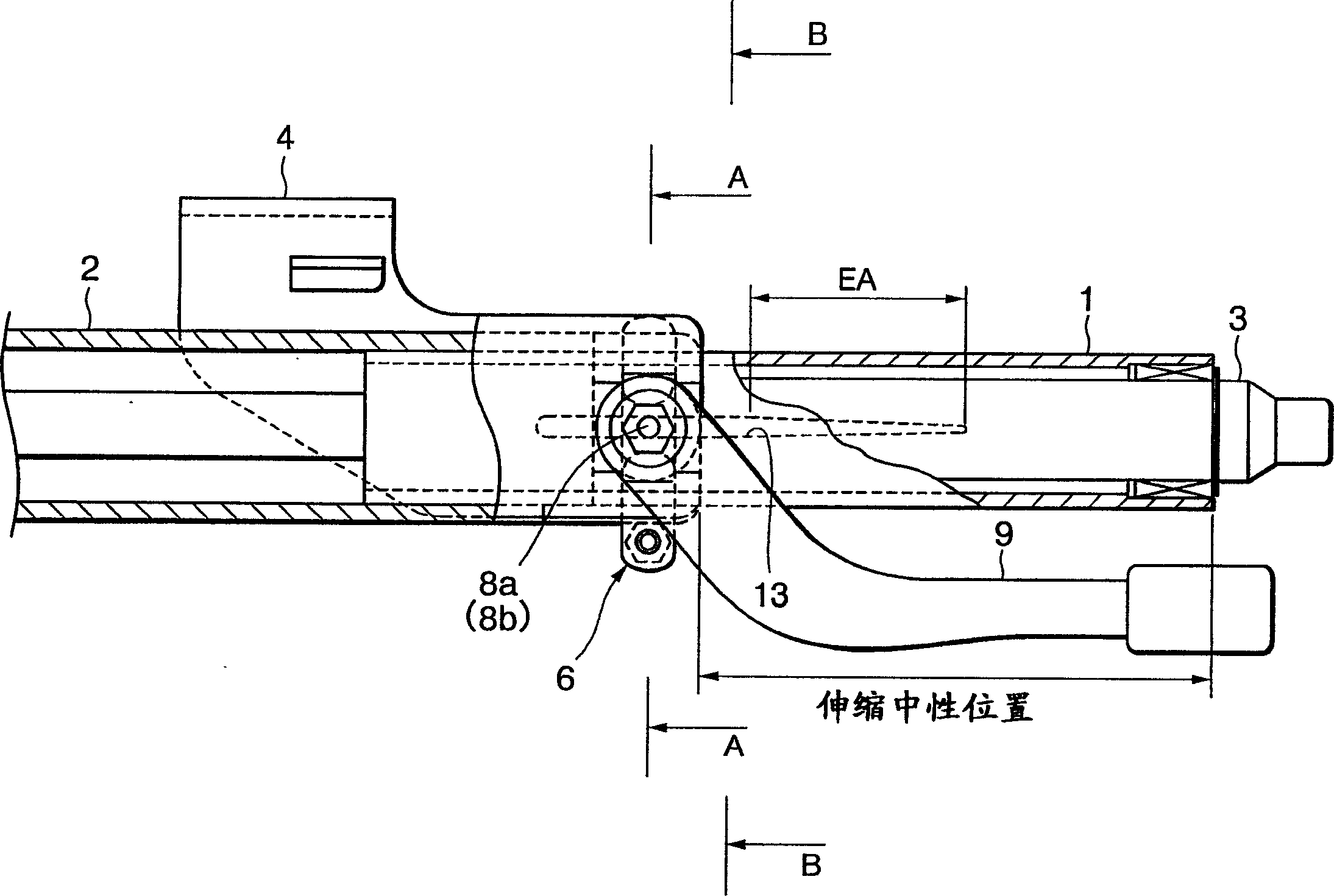

[0036] figure 1 It is a side view of a tilt / telescopic adjustable shock-absorbing steering column device in a first embodiment of the present invention.

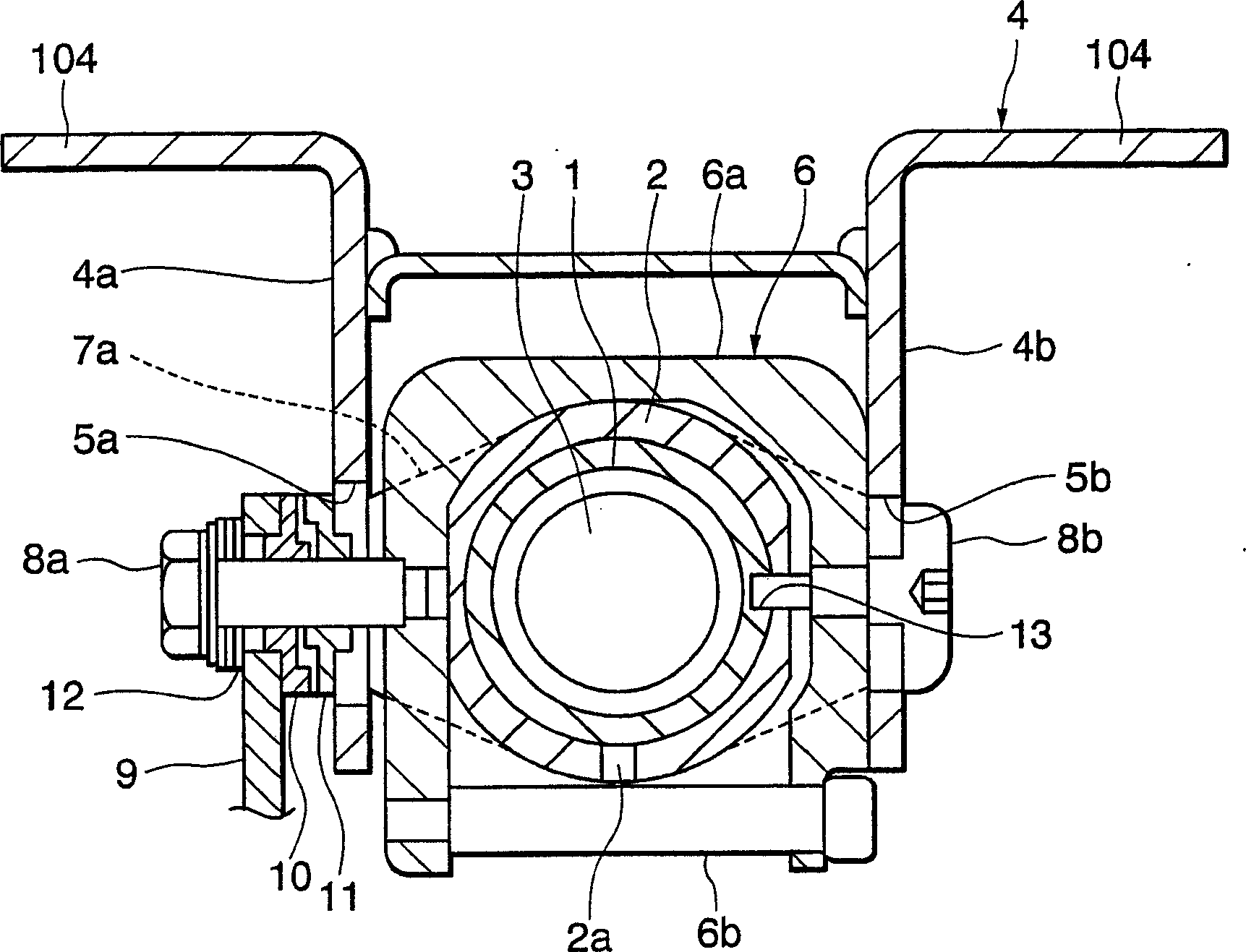

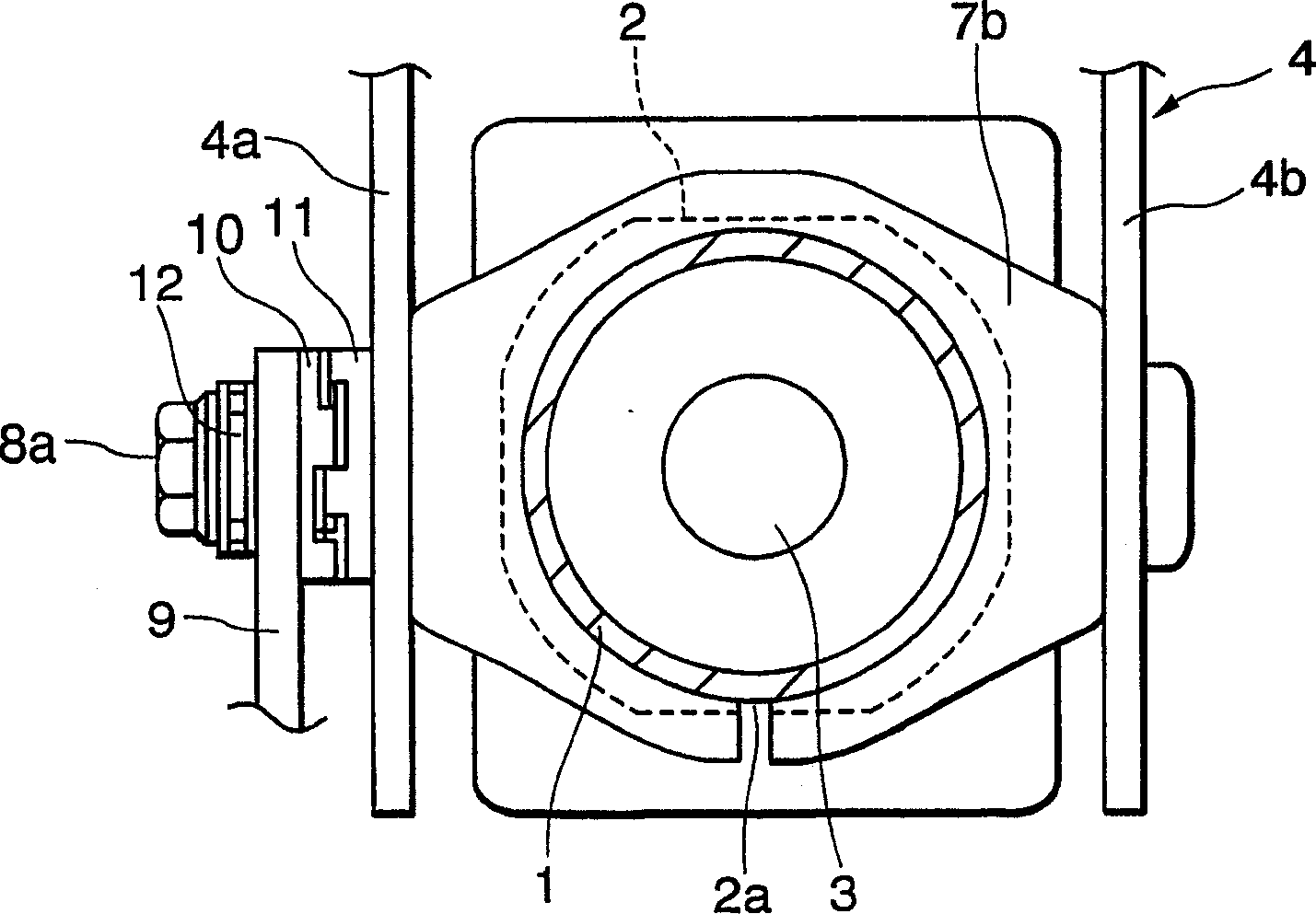

[0037] Figure 2A and 2B respectively figure 1 Middle A-A Online and figure 1 Sectional view on line B-B in middle.

[0038] image 3 to show figure 1 Side view of a shortest position in a telescoping adjustment of the steering column arrangement shown.

[0039] Figure 4 It is a view showing the termination state of shock absorption caused when a secondary collision occurs.

[0040] Such as figure 1 , 2A As shown in and 2B, the first embodiment shows an example of a fastening lock mechanism of a central holding type tilt / telescopic adjustment device. An inner pipe string 1 is slidably and telescopically fitted in an outer pipe string 2 . A steering shaft 3 is rotatably mounted in the two pipe columns 1 and 2 .

[0041] The outer column 2 is fixed on the vehicle body by the horizontal extension 104 of the vehicl...

no. 2 example

[0063] Figure 5 It is a side view of a tilt / telescopic adjustment type shock absorbing type steering column device according to a second embodiment of the present invention. In the second embodiment, a casing 102 integrally formed with the outer pipe string 2 described below is integrally formed with a gear case of an electric power assist (electric power steering (EPS)) device.

[0064] Figure 6 for along Figure 5 Sectional view of line B-B in middle.

[0065] The second embodiment includes a column assist type electric steering (EPS) device, and is an example of a tilt / telescopic fastening lock mechanism in which a fastening bolt is directly passed through the housing. The vehicle body side bracket 4 on which the horizontal portion 104 is fixed is integrally formed with a pair of side plate parts 4a, 4b extending in the vertical direction, and the outer pipe column 2 is arranged between the two side plate parts. A pair of surrounding members 30a, 30b having a larger w...

no. 3 example

[0081] Figures 7A-7C A third embodiment is shown. Figure 7A is a half-sectional view of a sleeve; Figure 7B It is a partial cross-sectional view of a modified example of an inner pipe string. Figure 7C It is a partial cross-sectional view of another modification example of an inner pipe string. Each of the sleeves is inserted into e.g. Figure 5 The steering column device shown is between the outer column 2 and the inner column 1 .

[0082] exist Figure 7A In the example, the inner surface of a sleeve 14 treated with low friction material along the Figure 5 The inner surface of the outer column 2 of the shown steering column device is mounted to a portion corresponding to the mating portion of the two columns. The low-friction material treatment is one of the following treatments: baking molybdenum disulfide, baking fluororesin, mixture of baking molybdenum disulfide and fluororesin, coating ceramics, metal soap treatment, low-friction plating treatment and coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com