Longitudinal sliding and vertical lifting mechanism of large-tonnage guy cable hanging basket main truss

A large-tonnage, basket-main technology, applied in the direction of lifting device, lifting frame, transportation and packaging, can solve the problems of the need to improve the installation accuracy, reduce the construction efficiency, increase the construction cost, etc., so as to improve the overall construction efficiency and vertical The effect of improving efficiency and reducing sliding load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

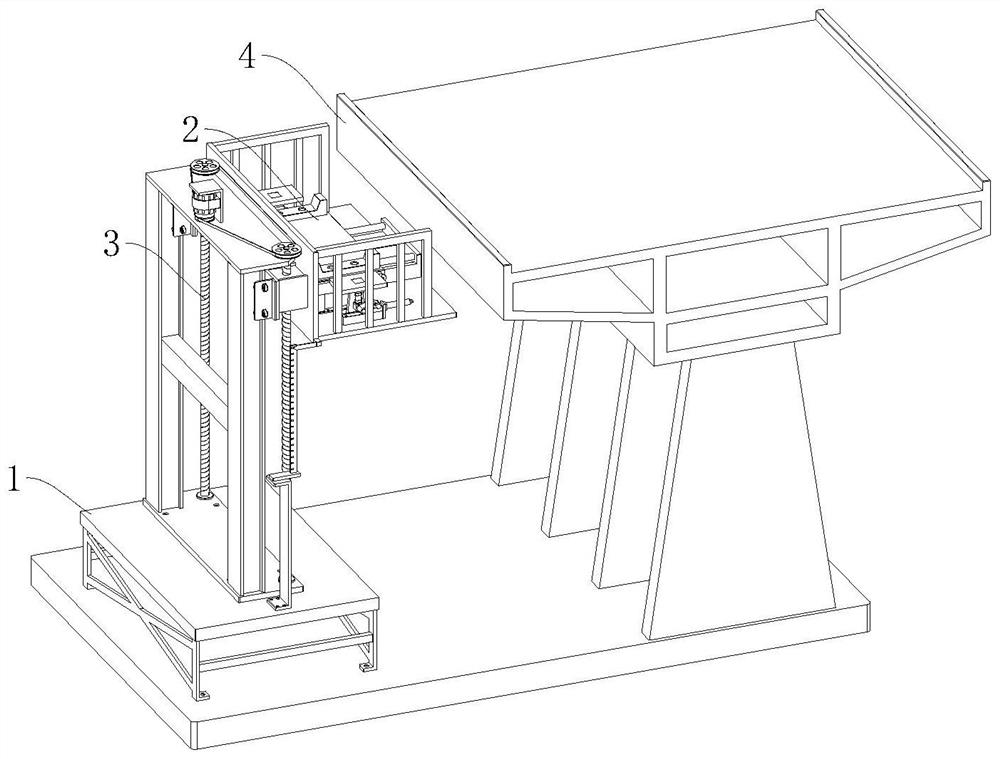

[0044] The present invention provides a technical solution, referring to figure 1 , a longitudinal sliding and vertical lifting mechanism of the main truss of a large-tonnage cable hanging basket, including a base 1, the base 1 is arranged on the ground,

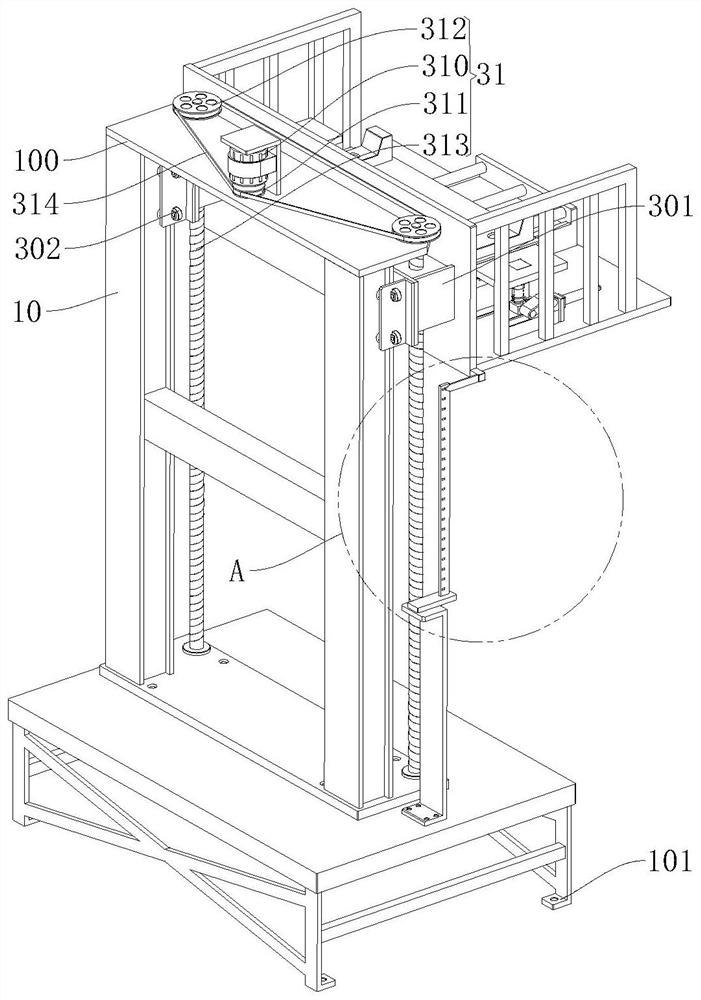

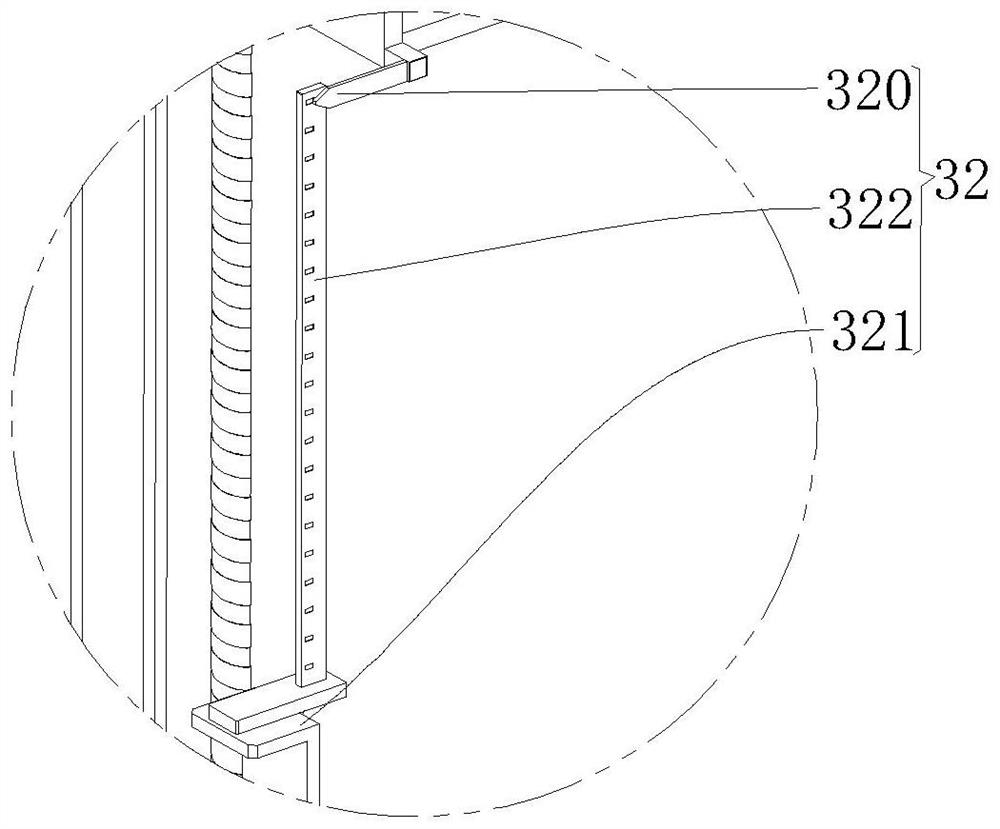

[0045] Also comprise controller, sliding device 2 and elevating device 3, elevating device 3 is arranged on the top of base 1 for lifting sliding device 2, and elevating device 3 comprises bearing frame 30, driving assembly 31 and measuring assembly 32, and driving assembly 31 Set on the top of the base 1, the bearing frame 30 is set on the drive assembly 31, the measuring assembly 32 is set on the top of the base 1, the sliding device 2 is set inside the bearing frame 30 to slide the main truss of the hanging basket, the sliding device 2 includes a loading platform 20, a push-pull assembly 21 and two locking assemblies 22, the loading platform 20 is slidably arranged inside the carrying frame 30, the push-pull assembly 21 i...

Embodiment 2

[0054] In order to ensure that the main truss of the hanging basket and the main beam 4 are installed in place, refer to Figure 5As shown, the inside of the bearing frame 30 is symmetrically provided with two vertical plates, and a long-axis cylinder 303 is inserted on the outer wall of each vertical plate, and a driving block 304 is fixed on its output end. The inside of the bearing frame 30 is shaped like Two support plates are arranged symmetrically, each support plate is slideably provided with an insertion rod 305, the bottom of the insertion rod 305 is fixed with a push rod 306, and the push rod 306 is plugged with the drive block 304, and the inside of the drive block 304 is provided with An arc-shaped contact groove for reciprocating sliding of the push rod 306, a limit block 307 is fixed on the top of the support plate, an adjustment plate 308 is fixed on the top of the insertion rod 305, a level sensor 309 is embedded in the inside of the adjustment plate 308, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com