Movement guide rail of machine tool

A motion and guide rail technology, applied in the field of machine tools, can solve the problems of adding springs, impossible, and existing errors, and achieve the effect of preventing yaw and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

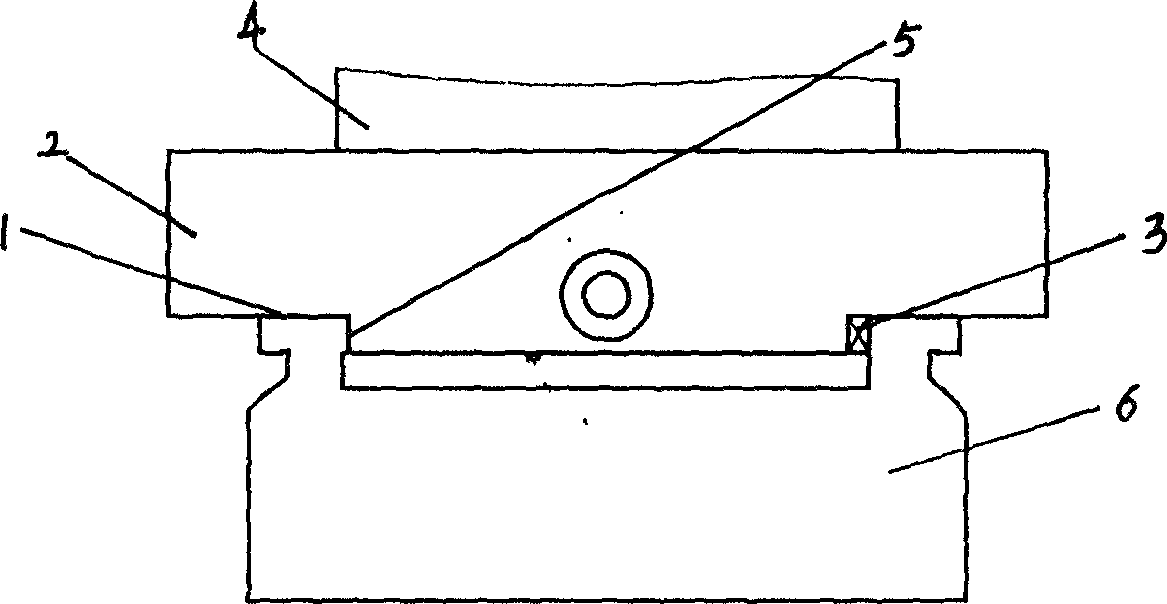

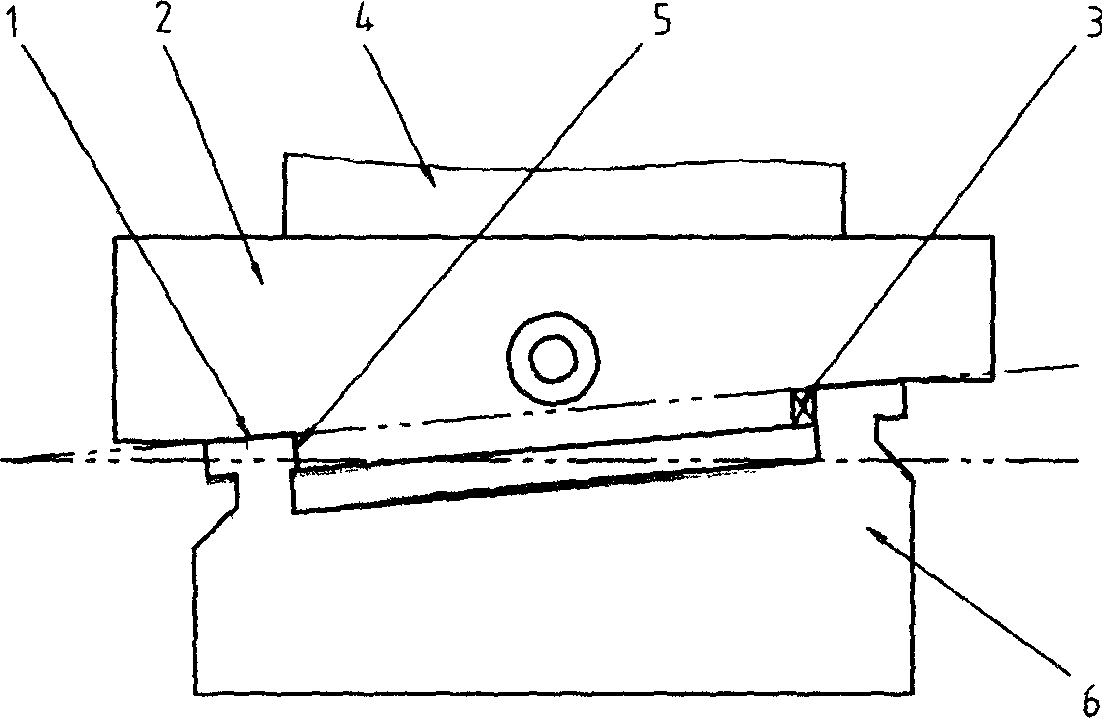

[0011] exist figure 2 Among them, the movable body 2 and the main body 6 are slidably matched through the main body, the reference surface, and the guide rail, and the workpiece 4 is placed above the movable body 2, and the upper end surface of the main body 6 that is in contact with the lower end surface of the movable body 2 is the gravity direction reference Surface 1, there is an included angle greater than zero between the reference plane 1 in the direction of gravity and the horizontal plane, the contact surface in the moving direction of the movable body is the reference plane 5 in the moving direction, and a pressing device 3 is installed between the movable body 2 and the body 6, The pressing device 3 is a wedge with an inclined surface.

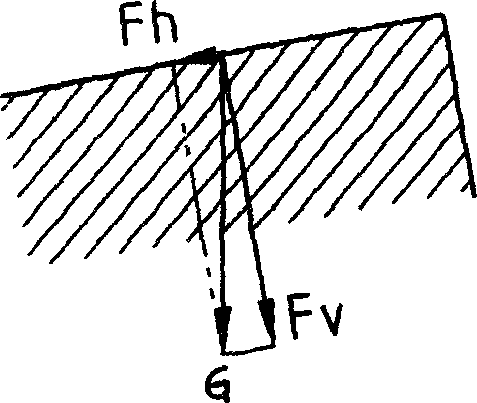

[0012] like image 3 The force analysis diagram of the reference plane 1 in the direction of gravity is shown. Gravity G is decomposed into forces in two directions, one is the component force Fh parallel to the reference plane 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com