Complex three phase AC motor

A technology of three-phase alternating current and three-phase alternating current, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of low motor efficiency and power factor, energy waste, etc.

Inactive Publication Date: 2005-10-19

刘鹏 +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this way, the efficiency and power factor of the motor are very low, resulting in serious waste of energy.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

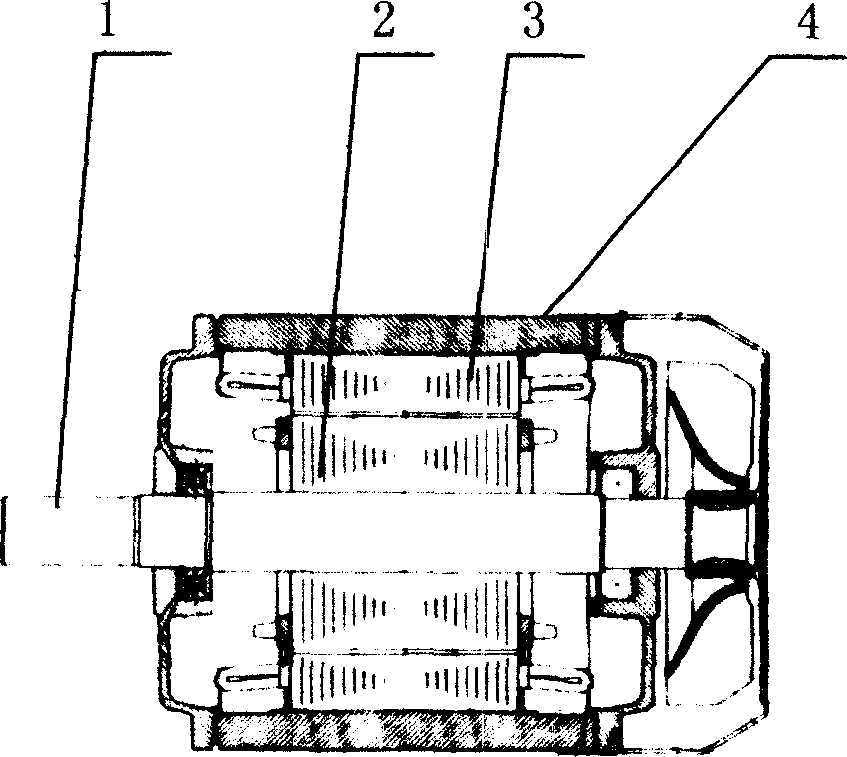

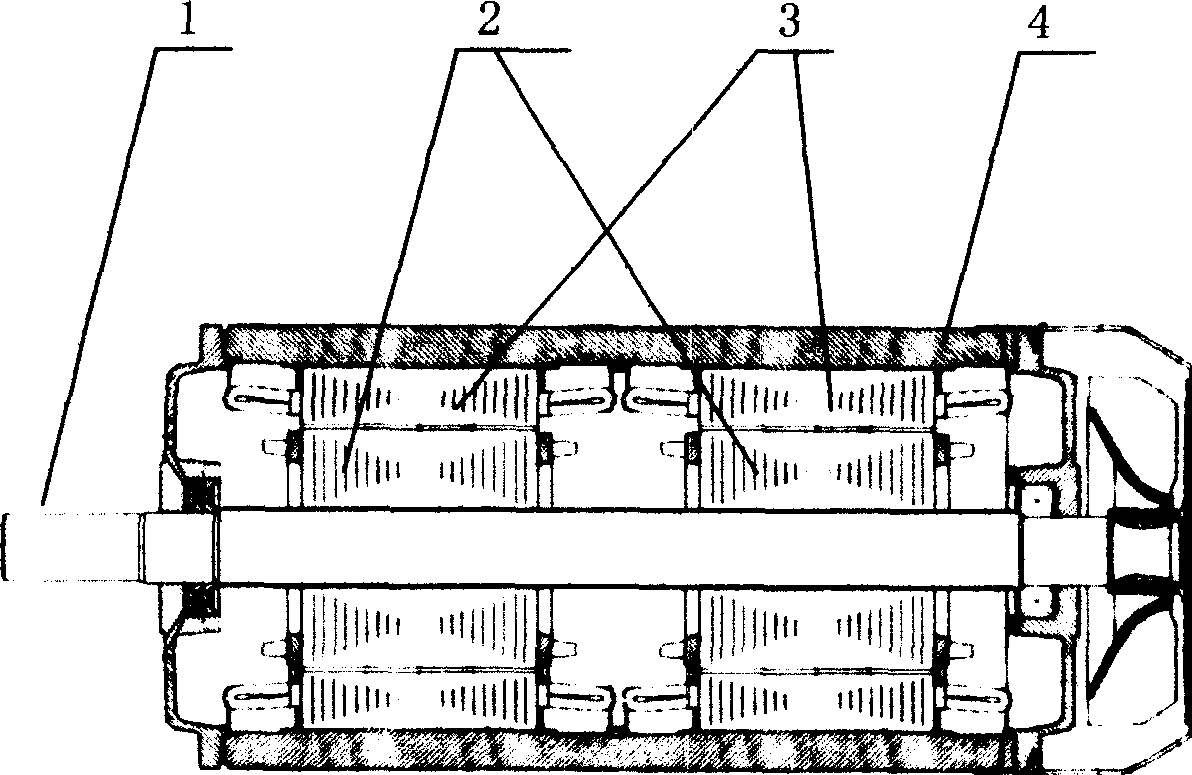

[0009] Two sets of three-phase AC motors are designed and manufactured in the same casing 4, which consists of two sets of stators 3 and two rotors 2 on the coaxial 1. When the load increases during startup or operation, the two sets of stators 3 are energized, that is, double After the load decreases, one set of stators 3 stops power supply, and the other set of stators 3 keeps energized, that is, it becomes a stand-alone operation.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The name of this invention is: a multiple 3-phase AC motor relating to many industrial fields of oils, mines, steels and cements. Many devices are very heavy when they start, large power motors should be prepared, yet, their load reduces after start, the output power of the motor is reduced too, thus its efficiency and power factor are low to result in heavy waste in energy. Now, a multiple 3-phase AC motor is used, which can ensure enough start moment at start since double motors operate, then one operates while the other stops running after it turns to normal operation. The stand-by supply can be shared by several synchronous motors.

Description

technical field [0001] The present invention relates to various industrial fields such as petroleum, mining, steel and cement. Background technique [0002] In various industrial fields such as petroleum, mining, steel, cement, etc., quite a lot of equipment has a heavy load when starting, and must be equipped with a large-power motor. The reduction, the load is often lower than 50% of the rated power. In this way, the efficiency and power factor of the motor are very low, resulting in serious waste of energy. Contents of the invention [0003] In order to save energy and improve the efficiency and power factor of the motor, dual-motor drive is used for equipment that requires high starting power and low operating power, that is, two motors with the same power or different power are connected coaxially. When starting, the two motors operate to ensure a sufficiently large starting torque, and after turning into normal operation and reducing the load, one motor stops and t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): H02K16/00H02K17/16

CPCH02K16/00H02K17/16

Inventor 刘鹏董建国

Owner 刘鹏

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap