In site synthetic measuring method and apparatus for conductivity of variable density fibre aggregate

A fiber aggregate, comprehensive measurement technology, applied in the direction of measurement device, specific gravity measurement, measurement distance, etc., can solve the problem that there is no combined in-situ measurement method and device, and achieve a high degree of automation, high test accuracy, and strong comprehensiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

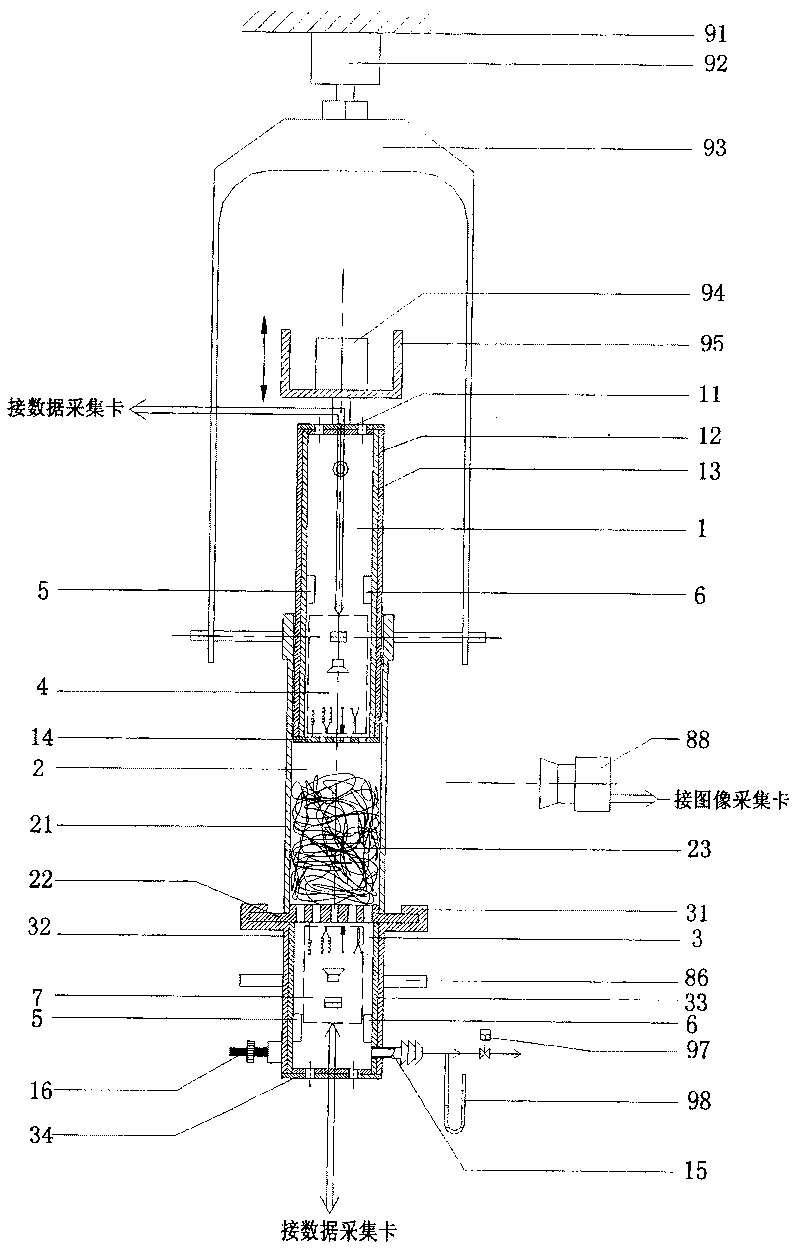

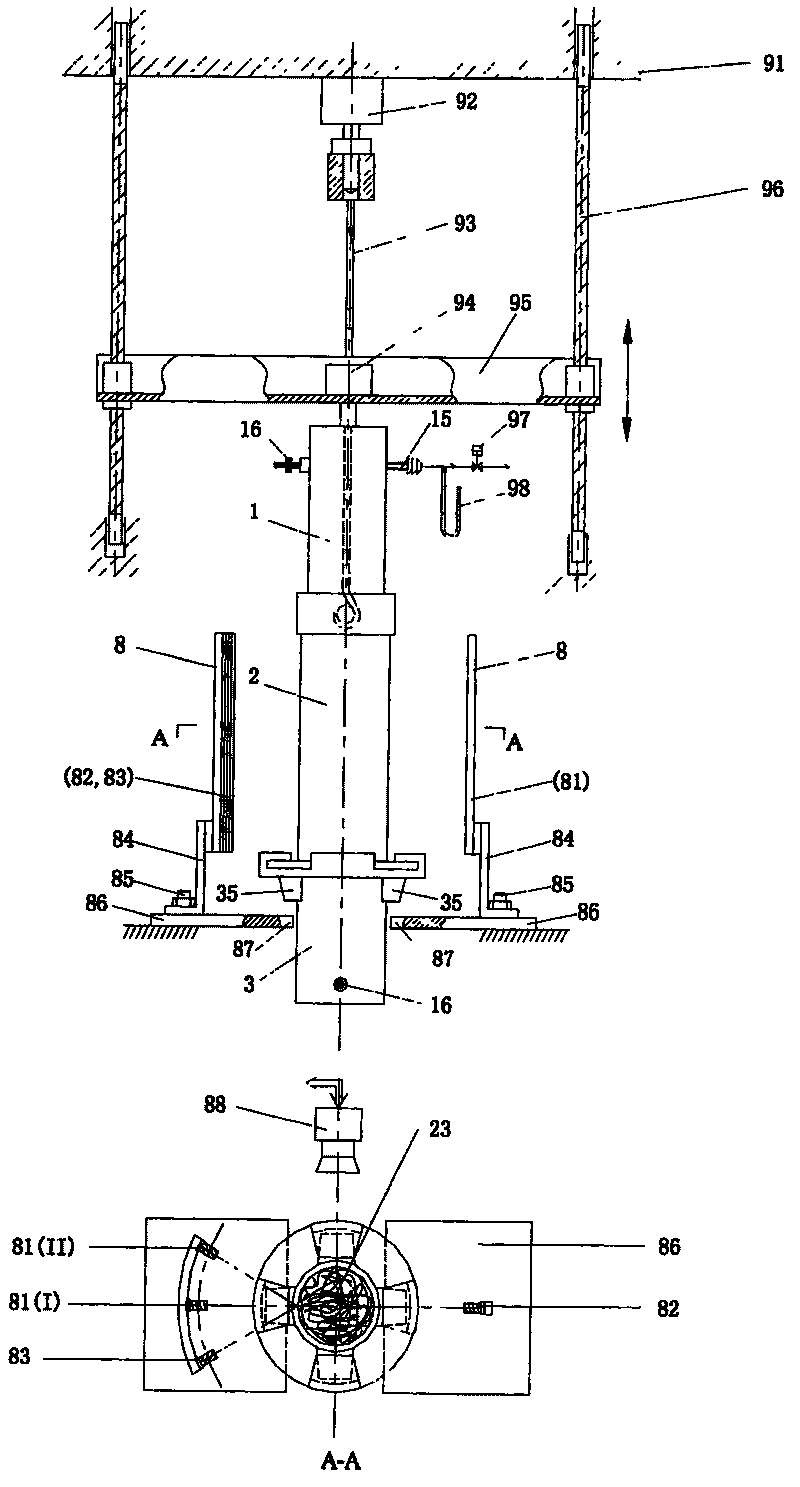

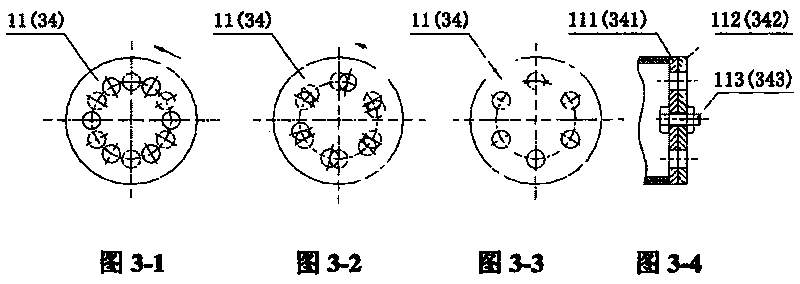

Embodiment 1

[0050] Using the in-situ comprehensive measuring device of the present invention, according to the above-mentioned actual measurement operation description, take 2g of wool fiber samples, fill them in the fiber plug tube 2 randomly and evenly in a natural relaxation state, and perform a compression mode extrusion. Fully open the air hole window 11 on the upper end of the push tube measuring chamber 1 before extrusion to ensure that the air pressure at one end of the fiber plug 23 is normal pressure; the air hole window 34 at the bottom of the lower measuring chamber 3 is completely closed, and start pumping to make the lower measuring chamber 3 produce a negative pressure. Press to form the air pressure difference ΔP at both ends of the fiber plug. Push cylinder to measure air pressure P in chamber 1 1 Measured by the air pressure sensor 46 in the upper measuring unit 4; the air pressure P of the lower measuring chamber 2 Measured by the air pressure sensor 76 in the lower me...

Embodiment 2

[0052] According to the sample and test conditions described in Example 1, while the extrusion test is applied, an electric field is applied to the wool fiber plug, that is, the electrodes 41 in the upper measurement unit 4 and the electrodes 71 in the lower measurement unit respectively apply an electric field to the fiber plug. Apply a voltage to the metal plates 14 and 22 of the end porous structure, and measure the current flowing through the fiber plug at this time to obtain the resistance R of the fiber plug. The fiber plug is constantly squeezed, and the resistance changes synchronously. As a result, the resistance R-fiber plug density ρ curve is shown in the attached Figure 7 Shown, is a clear resistance attenuation process.

Embodiment 3

[0054] According to the sample and test conditions described in Embodiment 1, while the extrusion test is applied, the wool fiber plug is subjected to acoustic action, that is, in the lower measurement chamber 3, the sound emitter 74 in the lower measurement unit 7 outputs a fixed frequency ( 4000Hz audio), the sound pressure is 82dB. The sound pressure intensity I measured by the acoustic sensor 75 in the lower measuring chamber 3 1 It is 79.4dB when it is not squeezed; the sound pressure I 2 , the percentage of sound pressure intensity at both ends of the fiber plug is α t =I 2 / I 1 ×100%. The measured sound intensity I-fiber plug density ρ curve and sound intensity percentage α t - fiber plug density ρ curve, respectively as Figure 8 with Figure 9 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com