Koaxialer resonator

A coaxial resonator and resonator technology, applied in resonators, waveguide devices, electrical components, etc., can solve problems such as metal wear and narrow tuning area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

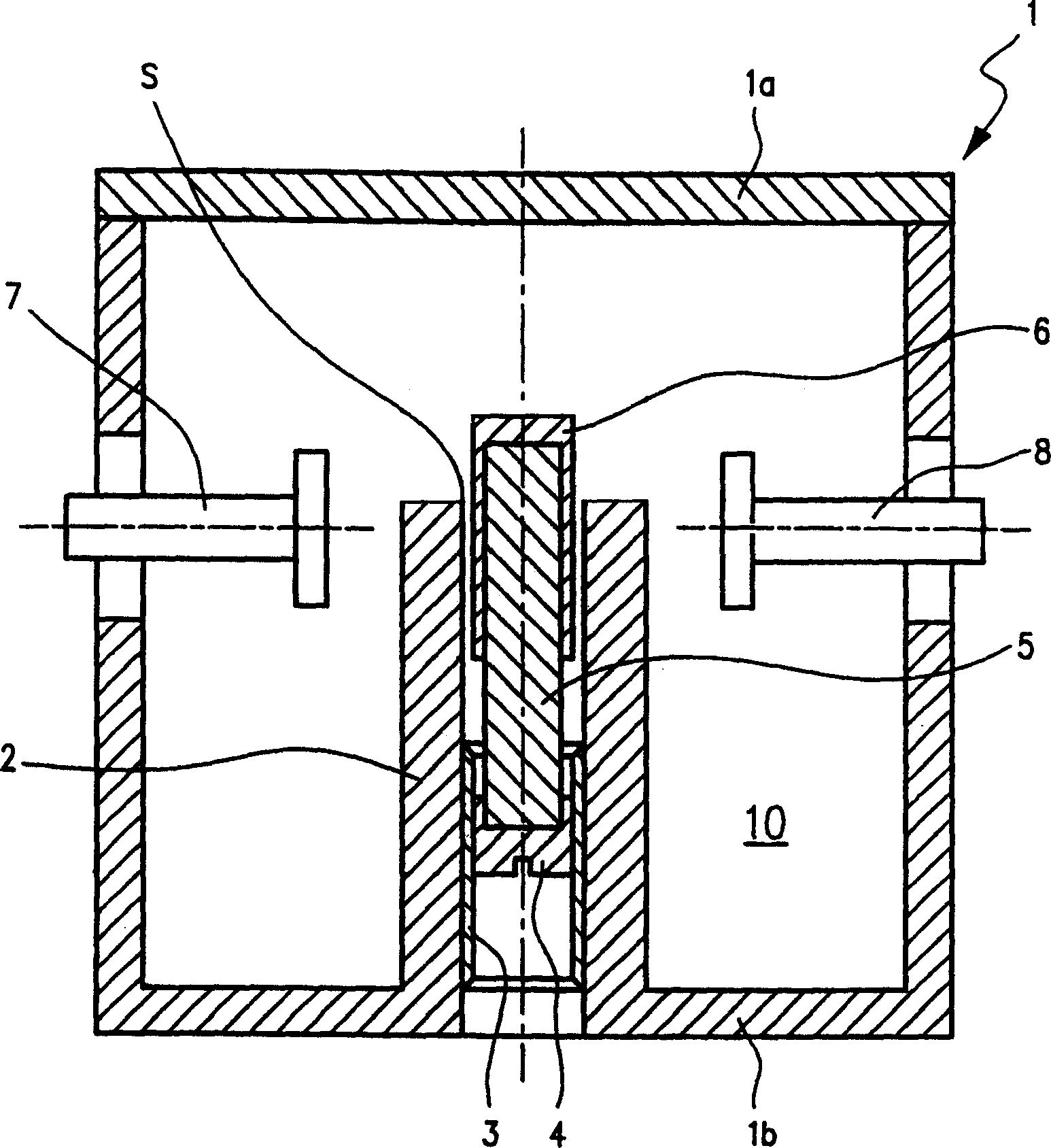

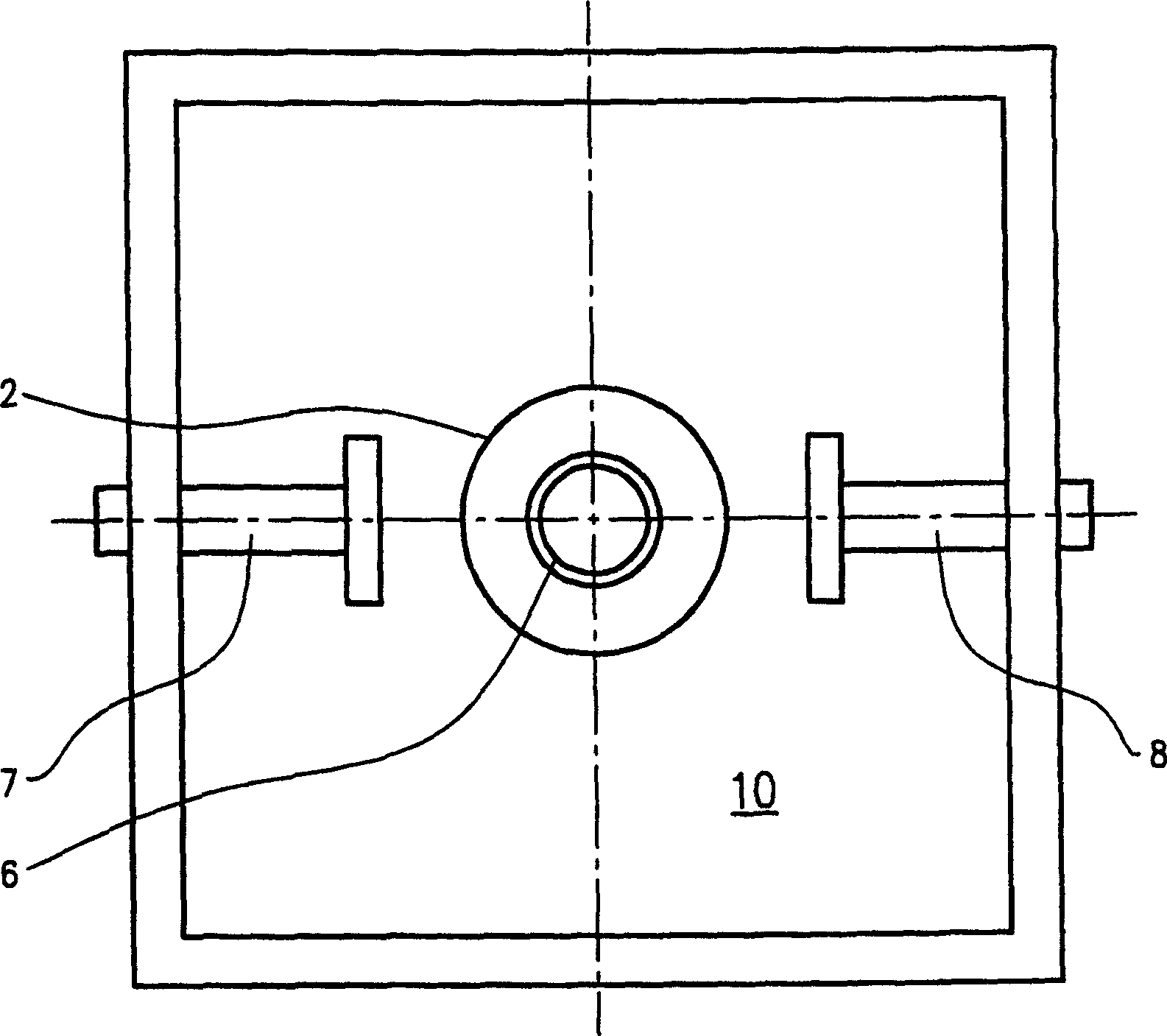

[0019] This embodiment involves a resonator having a center or resonant frequency of 1750 MHz and a tuning range of 640 MHz. This resonator is part of a four-loop bandpass filter for mobile communications.

[0020] The resonator comprises a cup-shaped metal housing 1 which in this embodiment is square in side and top view. However, other geometries are also possible. The housing 1 is closed in a high-frequency-tight manner by a cover 1a. A tube 2 extends from the middle of the housing bottom 1b in the direction of the cover 1a. As shown, the tube 2 may be integral with the bottom 1b. Press or glue a threaded sleeve 3 into the pipe 2 from the opening on the bottom side. The threaded sleeve 3 has an internal thread portion, and a tuning screw 4 is screwed into the internal thread portion. The tuning screw 4 receives the lower end of a ceramic rod 5 . A metal sleeve-shaped or cup-shaped tuning body 6 is fitted over the upper end of the ceramic rod, said tuning body is conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com