A three-dimensional assembly and packaging structure of a microwave module based on a silicon-aluminum alloy box

A technology of silicon-aluminum alloy and packaging structure, which is applied in the direction of semiconductor devices, electric solid-state devices, semiconductor/solid-state device components, etc., can solve the problem of low integration, incapable of hermetic packaging, and high integration of three-dimensional and three-dimensional components. The urgent requirements and other issues, to achieve the effect of solving high integration requirements and improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039]The silicon-aluminum alloy raw materials with different compositional gradients are prepared through an integrated molding process to obtain gradient aluminum-silicon electronic packaging materials, and then the raw materials are processed into a designed structural form; this process can be adopted with a patent number: 201510812388. The technical solution titled "A Preparation Method for Gradient Aluminum-Silicone Electronic Packaging Material" was prepared, and the specific steps included: (1) Aluminum-silicon material was prepared by casting or powder metallurgy, and silicon particle refinement was obtained by friction stir processing. , dense aluminum-silicon alloy with uniform distribution; (2) Drill evenly distributed blind holes on the aluminum-silicon alloy, fill the holes with silicon powder and compact them, and obtain a certain thickness of aluminum-silicon composite material layer through friction stir processing (3) Repeating step (2), by controlling the siz...

Embodiment 1

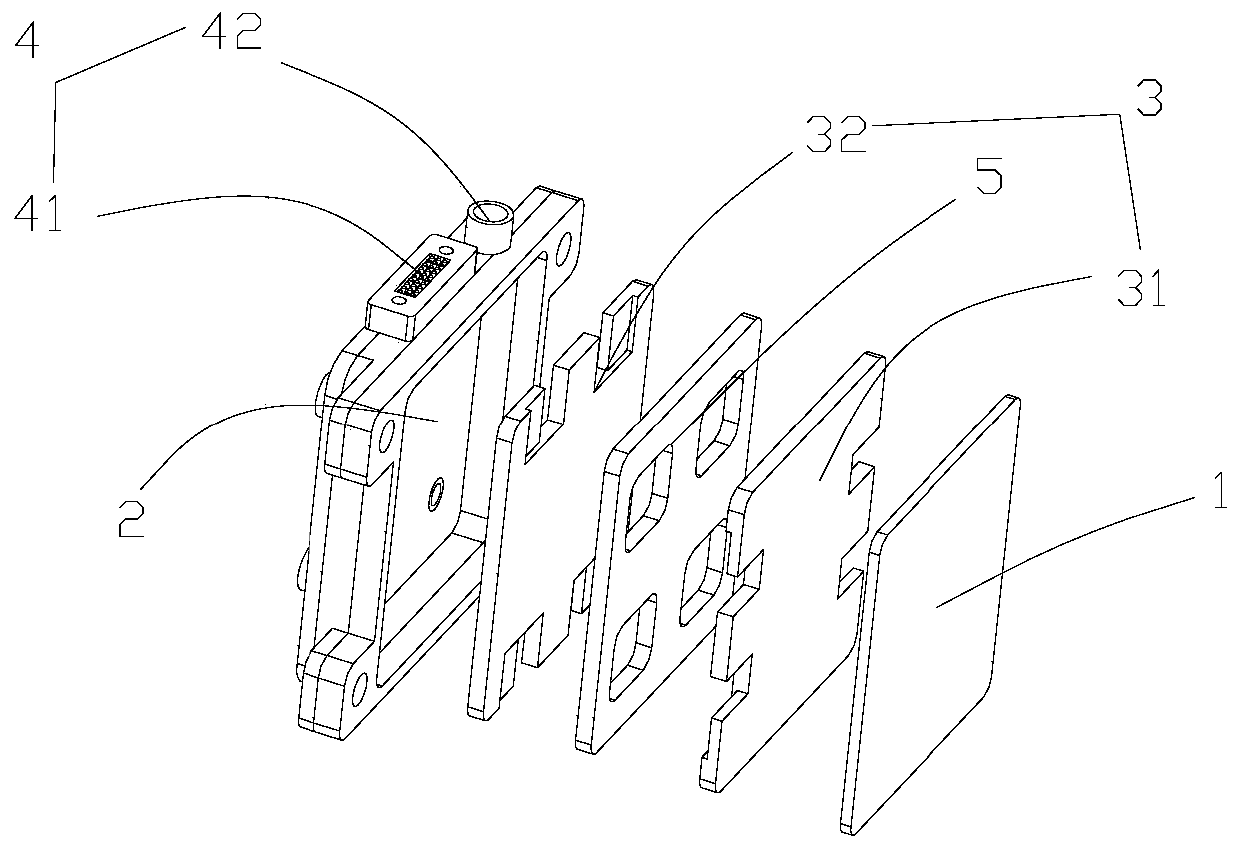

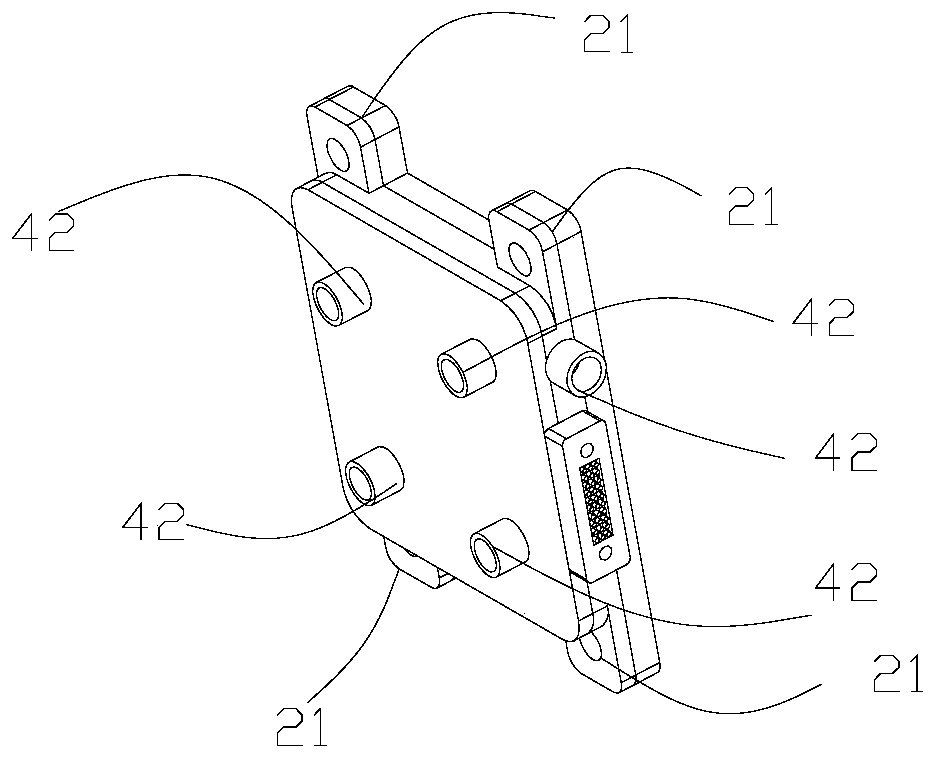

[0047] Such as Figure 1-2 As shown, a three-dimensional assembly and packaging structure of a microwave module based on a silicon-aluminum alloy box in the present invention consists of a cover plate 1, a housing 2, and two functional units 3 composed of an electronic substrate, heat sink, bare chip, components, etc. , the first functional unit 31 is assembled on the inner side of the cover plate, the second functional unit 32 is assembled on the inner side of the bottom of the housing, the connector 4 includes a low frequency connector 41, a radio frequency connector 42, and ribs 5 between adjacent functional units composition.

[0048] In this embodiment, the cover plate is a silicon-aluminum alloy with a grade of CE11, the shell is a gradient alloy of different components of silicon-aluminum, and the transition layer is a silicon-aluminum alloy with a grade of CE13, wherein the bottom material of the casing is CE11, and the integrated The frame material (including transit...

Embodiment 2

[0055] The difference from Embodiment 1 lies in: 1) the installation position of the connector, 2) the number and position of the lugs of the housing, specifically related to the following:

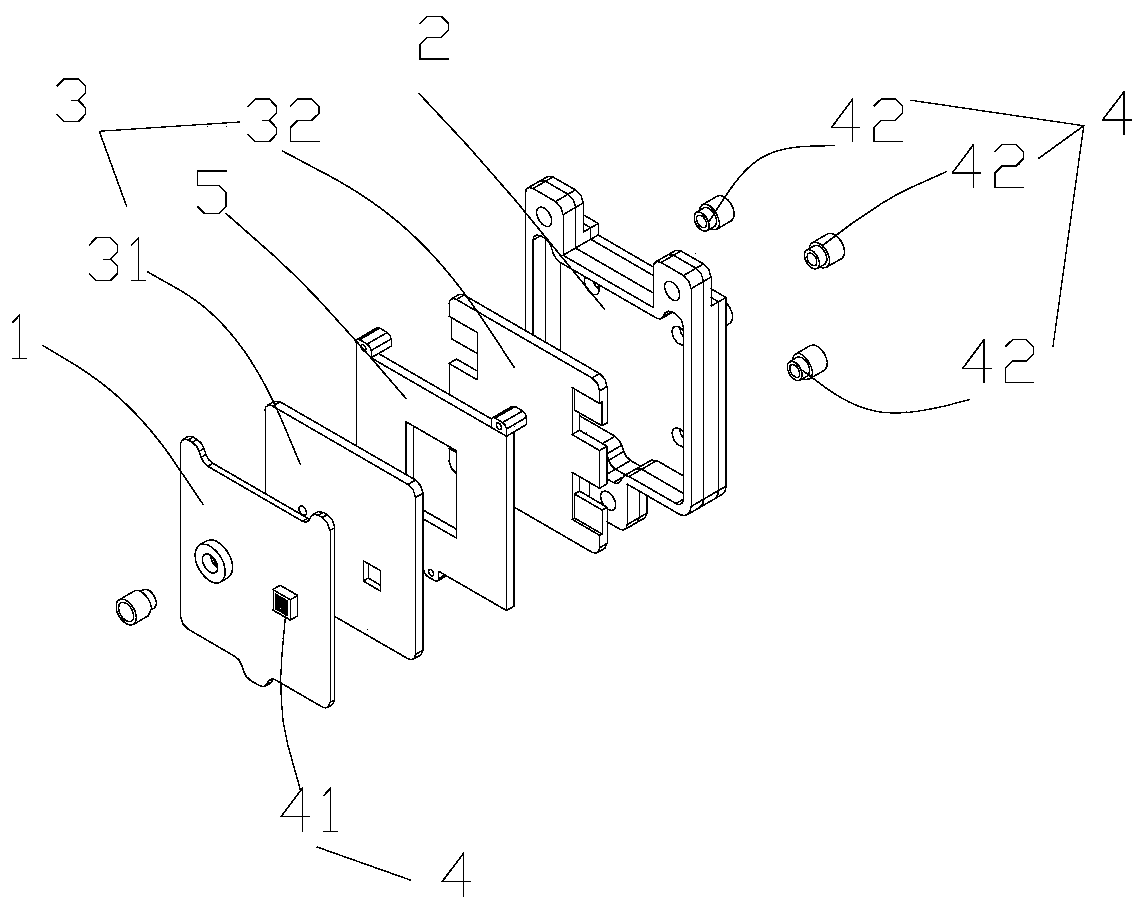

[0056] Such as Figure 3-4 As shown, a three-dimensional assembly and packaging structure of a microwave module based on a silicon-aluminum alloy box in the present invention consists of a cover plate 1, a housing 2, and two functional units 3 composed of an electronic substrate, heat sink, bare chip, components, etc. , the first functional unit 31 is assembled on the inner side of the cover plate, the second functional unit 32 is assembled on the inner side of the bottom of the housing, the connector 4 includes a low frequency connector 41, a radio frequency connector 42, and ribs 5 between adjacent functional units composition.

[0057] Among them, the cover plate 1 is silicon-aluminum alloy of grade CE11, and the shell 2 is a silicon-aluminum gradient alloy, and is respectively a sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com