Thermal protection system and method for gas turbine components

A gas turbine, thermal protection technology, applied in the direction of engine components, superimposed layer plating, blade support elements, etc., can solve problems such as ceramic parts or joint failures, achieve stress relief levels, heat flux reduction, cooling Effect of Air Consumption Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] see figure 1 , a gas turbine 1 (not shown in its entirety) has at least one component 2 provided with a thermal protection system 3 .

[0043] For example, the member 2 is a blade 2a or a blade support portion 2b. However, it should be understood that other components 2 of the gas turbine 1 may require thermal protection and thus may be provided with the thermal protection system 3 of the present invention.

[0044] The thermal protection system 3 comprises a high temperature resistant ceramic element 4 coupled to the metal wall 5 of the component 2 .

[0045] The component 2 or at least the wall 5 is made of metallic material.

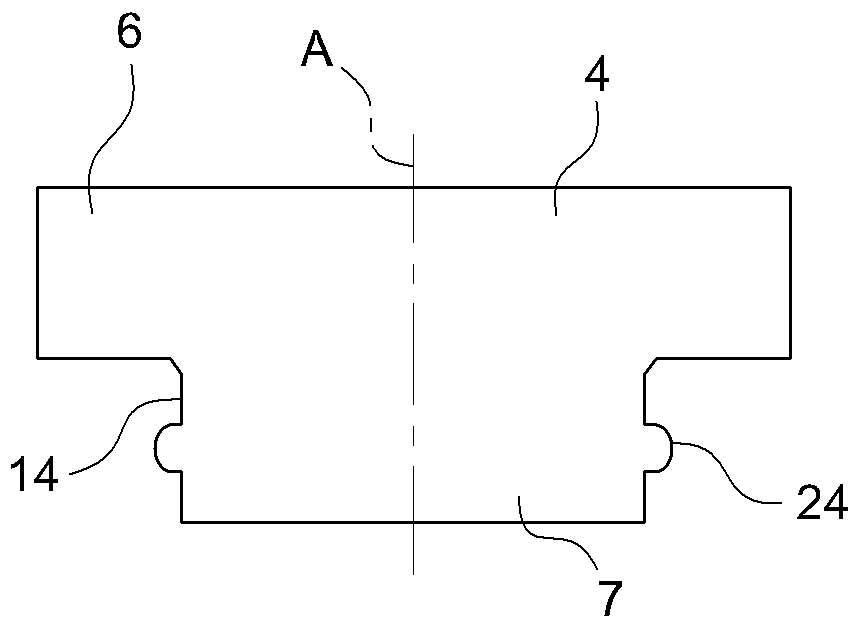

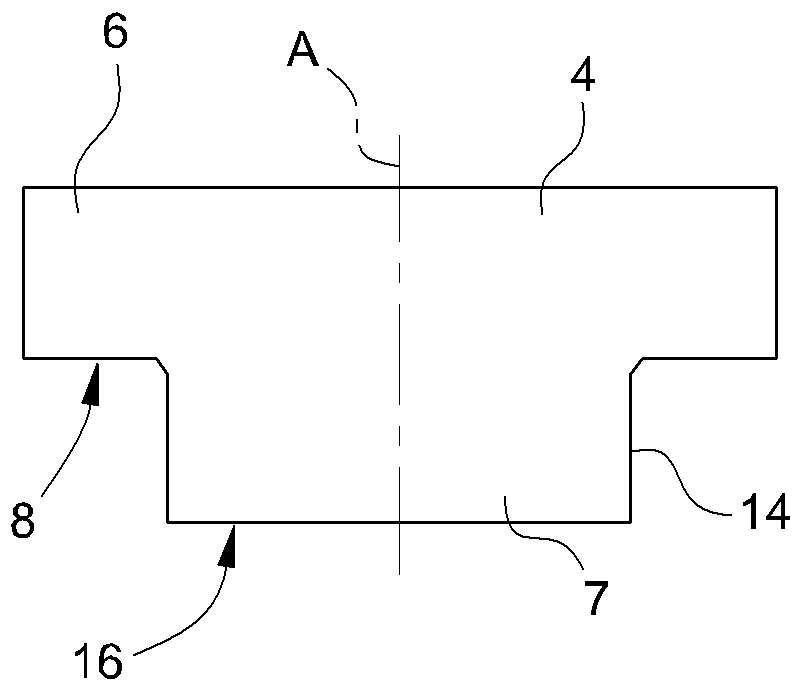

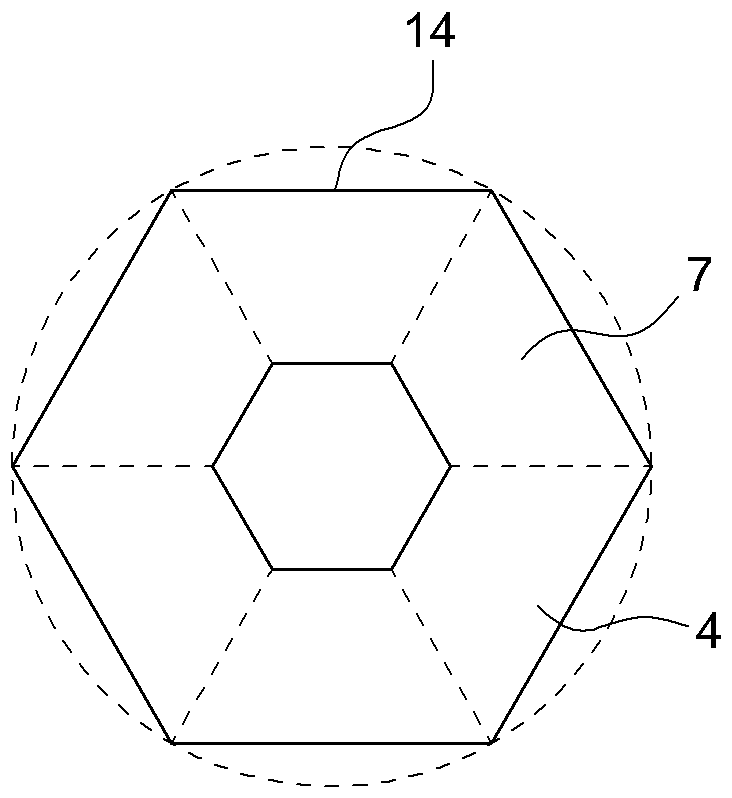

[0046] see also figure 2 and image 3 The ceramic element 4 , for example in the form of a covering tile, comprises a main body 6 and a root portion 7 protruding from a bottom surface 8 of the main body 6 .

[0047] Preferably, the ceramic element 4 is a single piece formed by the body 6 and the root portion 7 and made of ceramic materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com