Back light for display device

A backlight unit and display technology, applied in optical components, instruments, optics, etc., can solve problems such as uneven brightness, low brightness, and non-luminous electrodes, and achieve the effect of solving uneven brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiments of the present invention are now described. Similar parts described in the above embodiments will not be repeated.

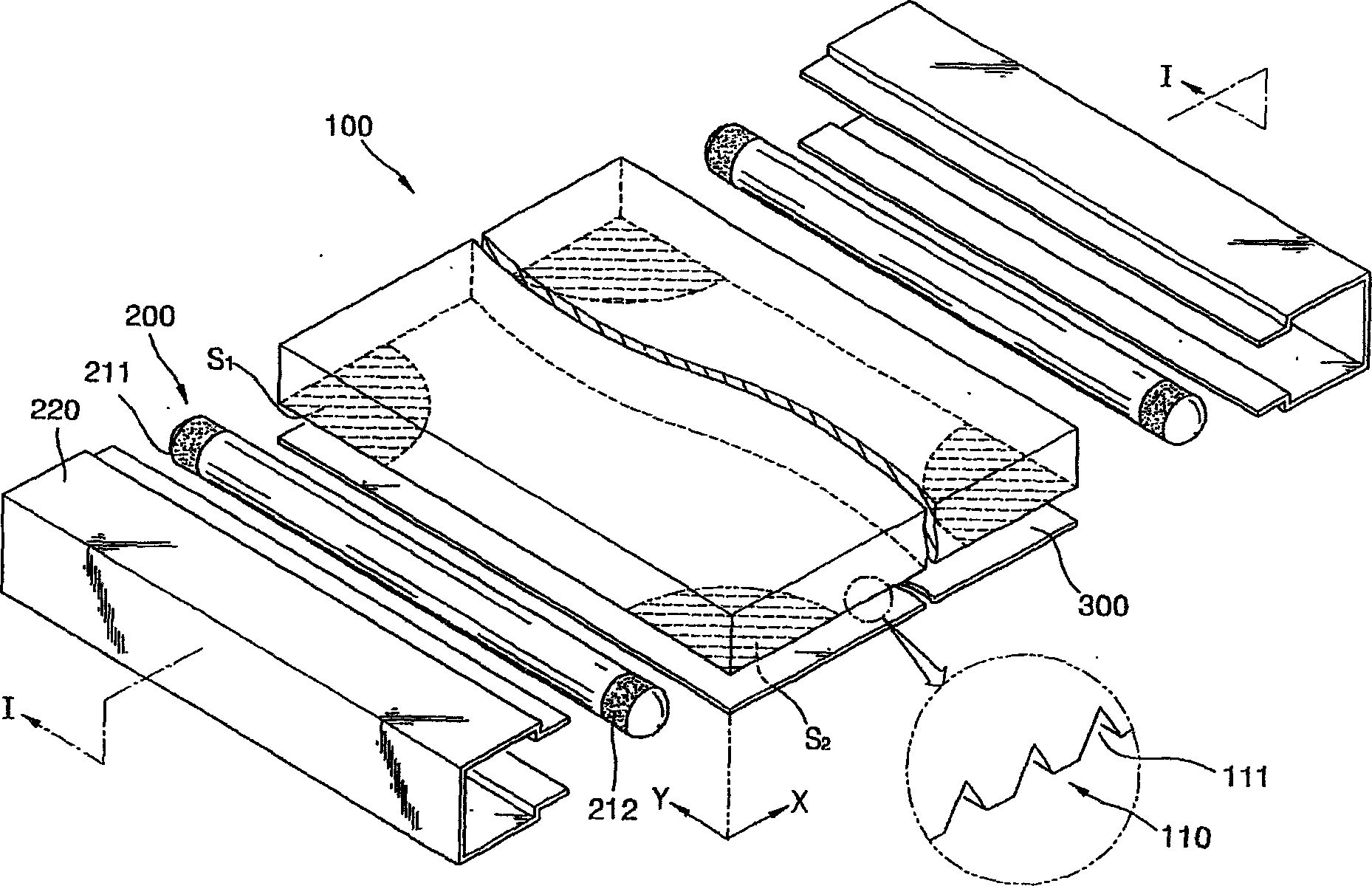

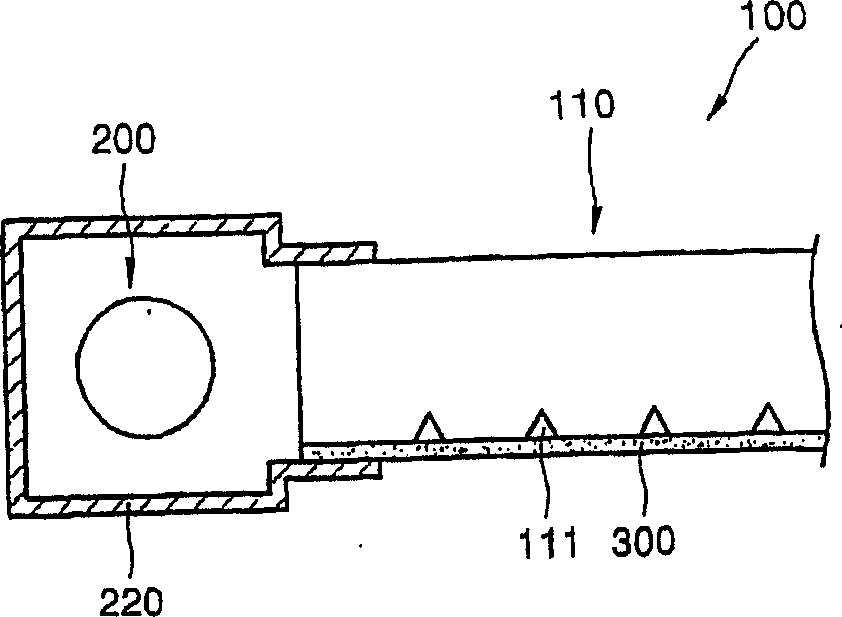

[0036] According to this embodiment, the density of the grooves 111 in the prism pattern, in the length direction of the light source 200 , increases continuously along the direction approaching the electrodes 211 and 212 of the light source 200 .

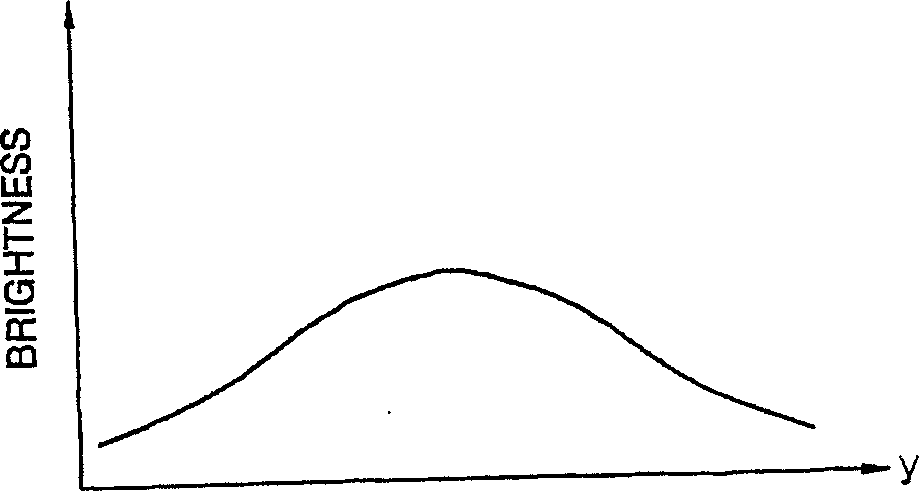

[0037] In this case, due to the reduced pitch of the grooves 111, in the regions S1 and S2 adjacent to the electrodes 211 and 121, the light refracted by the pattern forming unit 110 is relatively more than other regions. Accordingly, the amount of light refracted out of the light guide panel 100 at an angle greater than total reflection increases. That is to say, the problem of uneven brightness in the length direction of the light source 200 is solved.

[0038] Also, by continuously increasing the density of the grooves 111 in the prism pattern in the pattern forming unit 110 away from the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com