Steam valve

A steam valve, main steam technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve problems such as difficulty in suppressing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

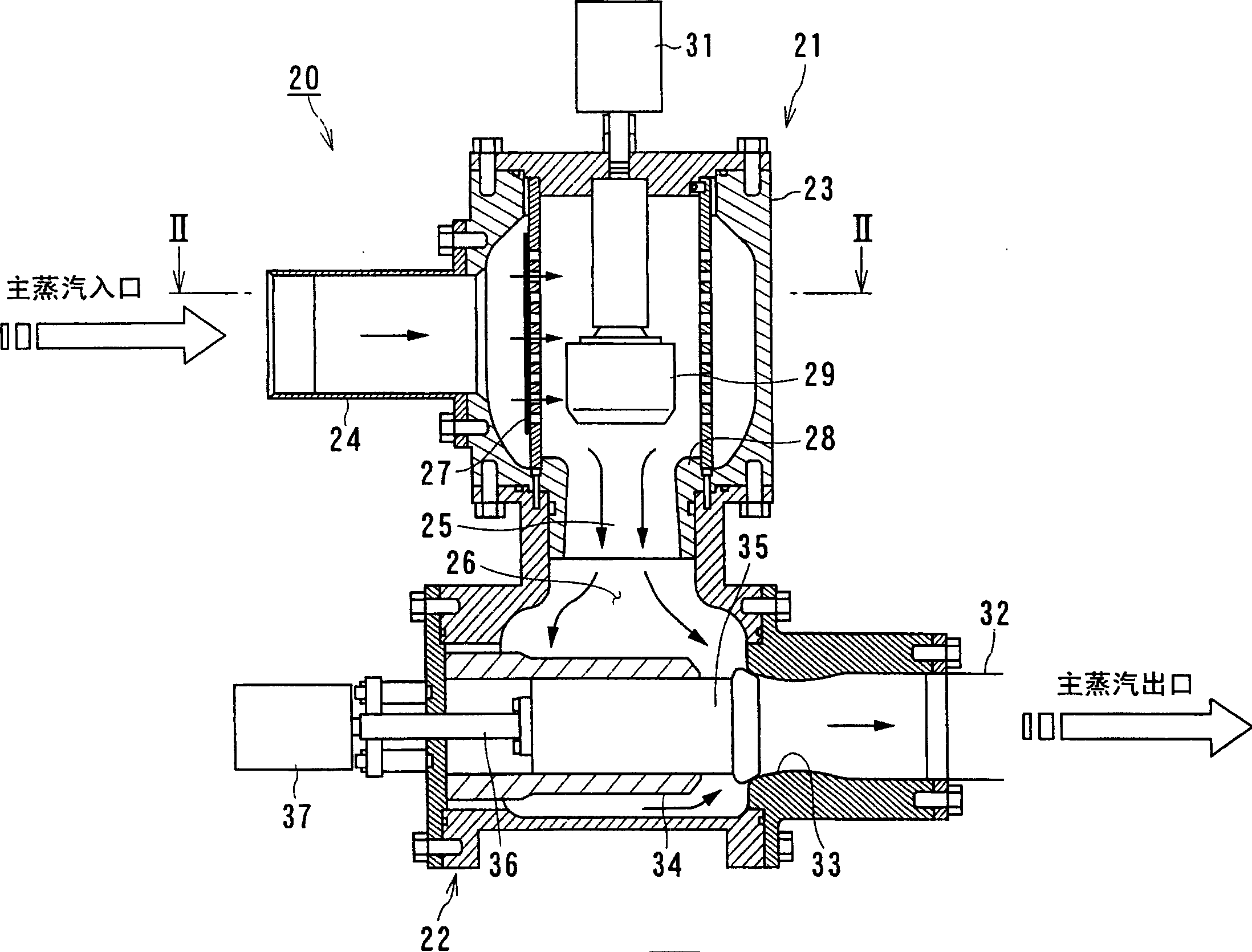

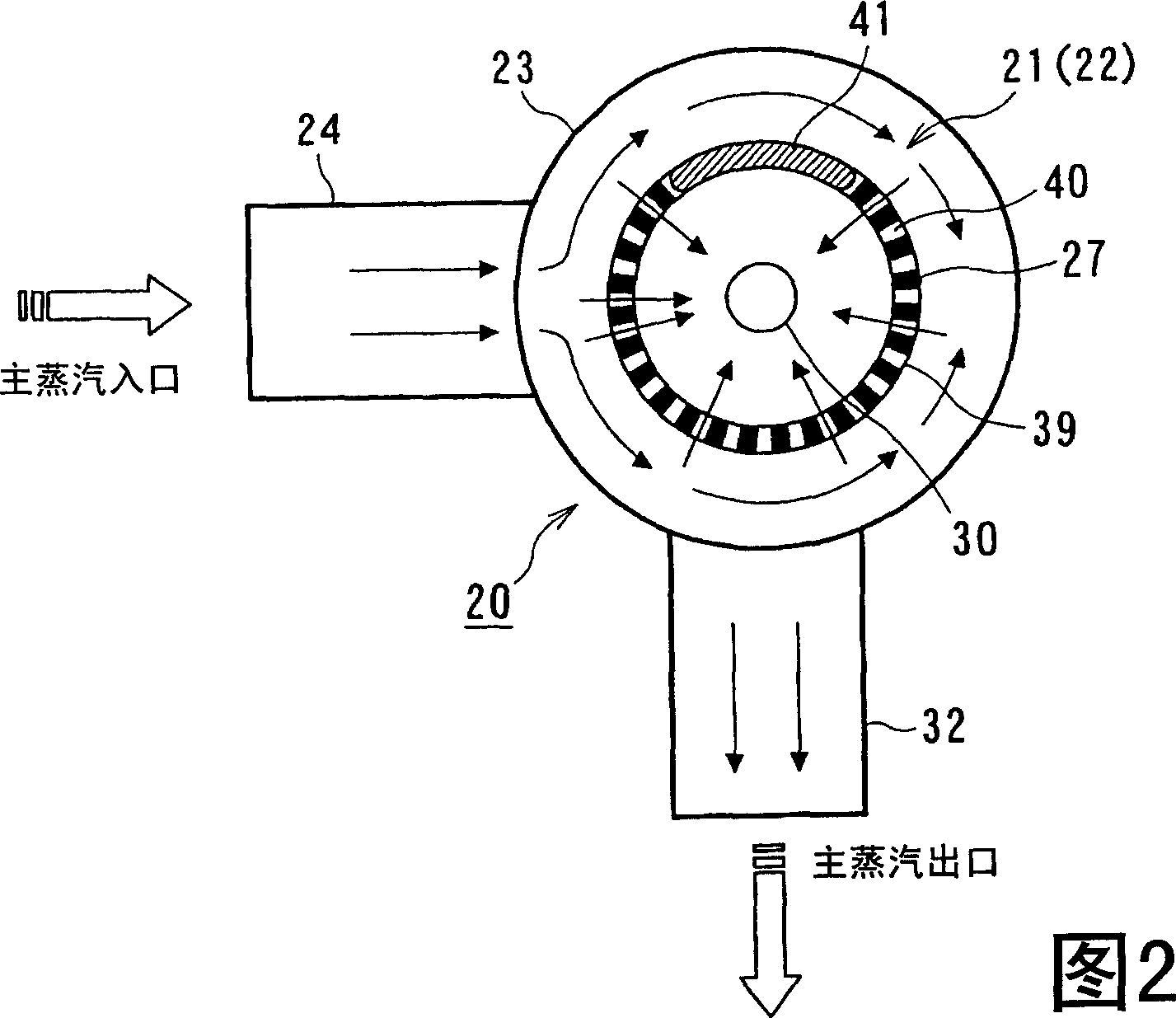

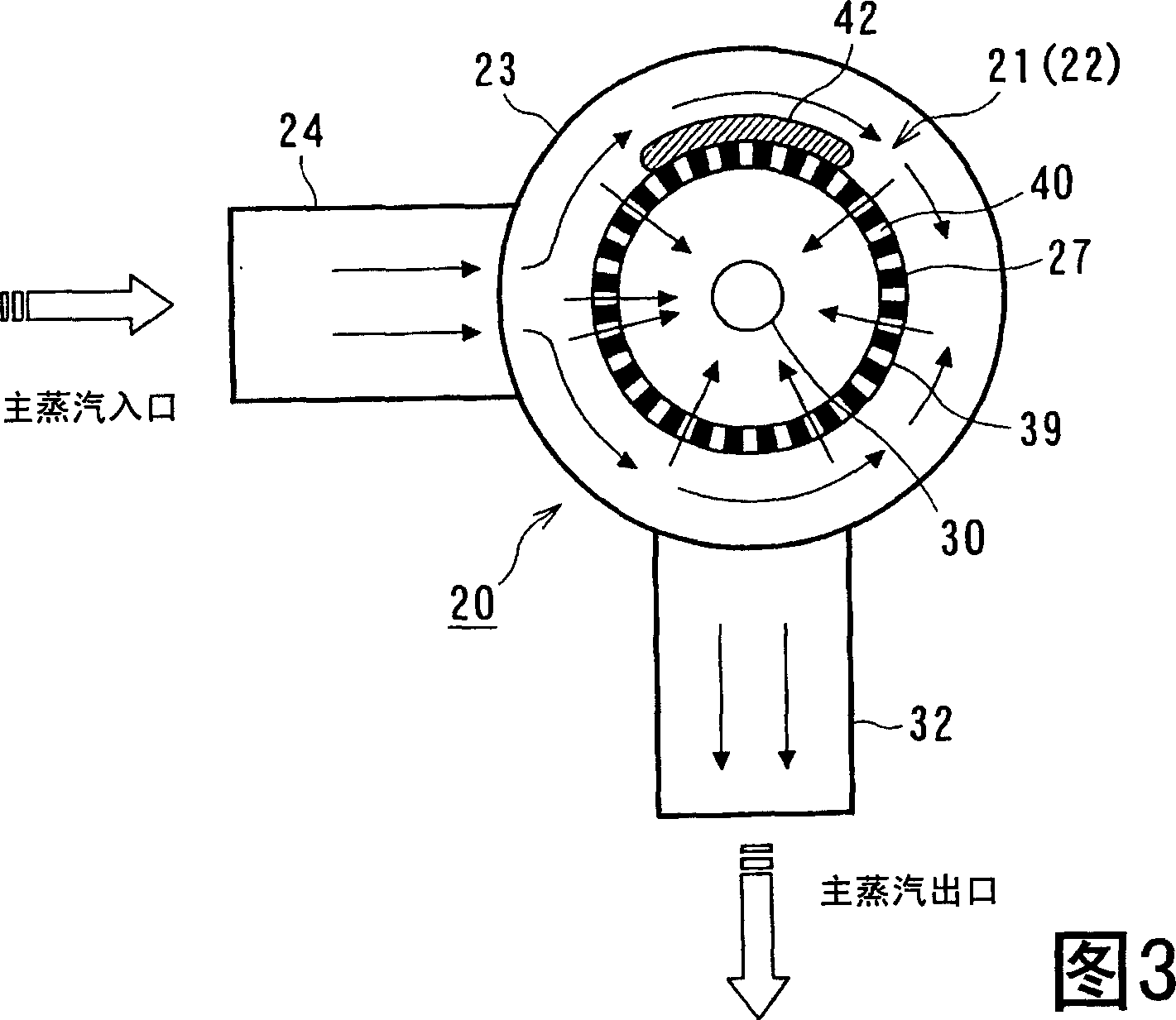

[0161] For the first embodiment, the steam valve 20 includes a main steam stop valve and a steam control valve (steam flow regulating valve) combined with each other, wherein the first valve device 21 corresponding to the main steam stop valve is arranged on the upstream side of the main steam flow, The second valve device 22 corresponding to the steam control valve (steam flow regulating valve) is arranged on the downstream side of the main steam flow, and further, the first valve device 21 and the second valve device 22 are accommodated in one valve housing 23 .

[0162] The first valve device 21 is provided with a first main steam inlet 24 and a first main steam outlet 25 connected to a second main steam inlet 26 of the second valve device 22 in the valve housing 23, and the first valve device 21 accommodates A filter 27 for removing impurities such as scale and the like.

[0163] In addition, the first valve device 21 is provided with a first valve body 29 and a first driv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap