Piston type automobile tractor and assembling method thereof

A tractor and piston-type technology, applied in traction connectors, vehicle parts, transportation and packaging, etc., can solve problems such as unreasonable structural design schemes and unsafe traction, and achieve a reasonable overall structure design, convenient operation, and high-tech The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

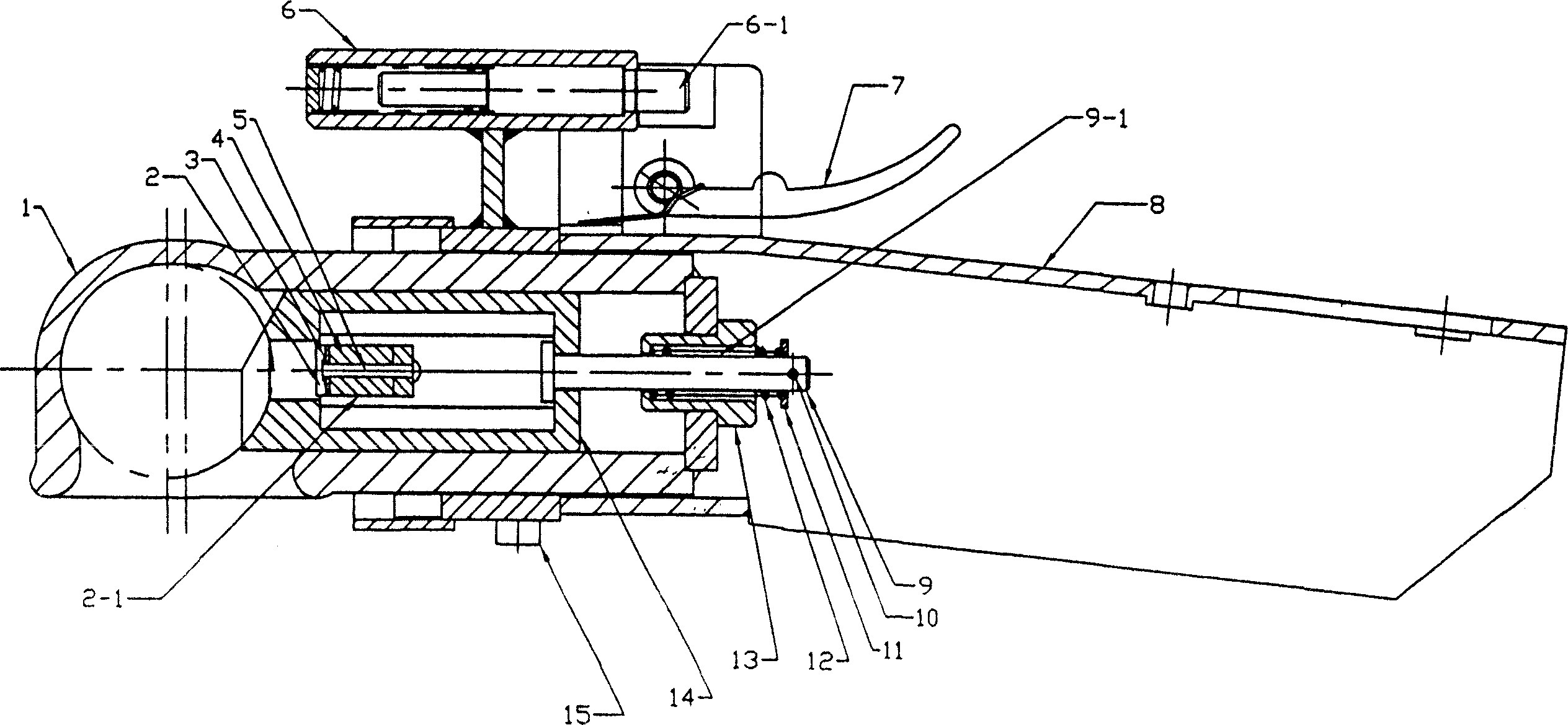

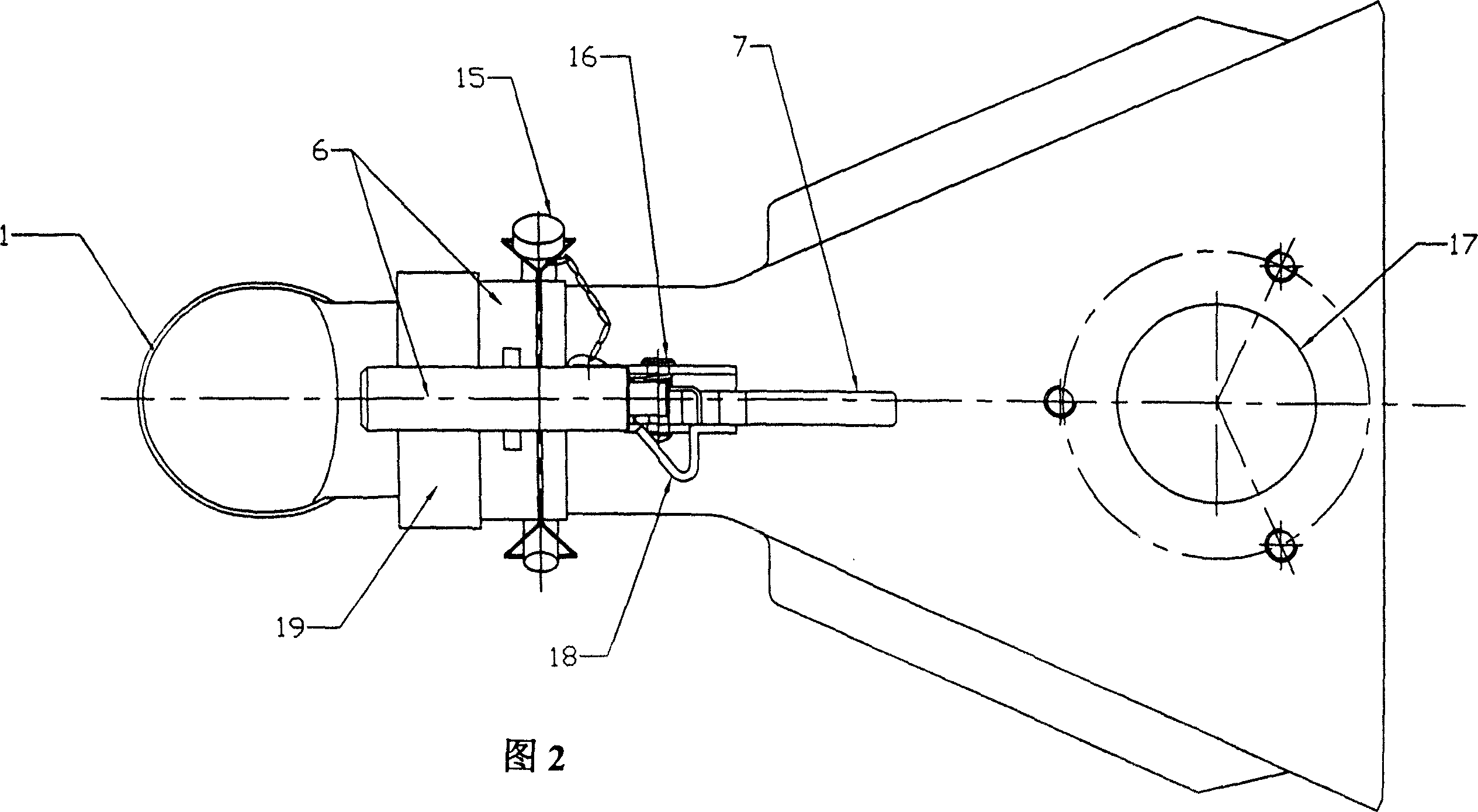

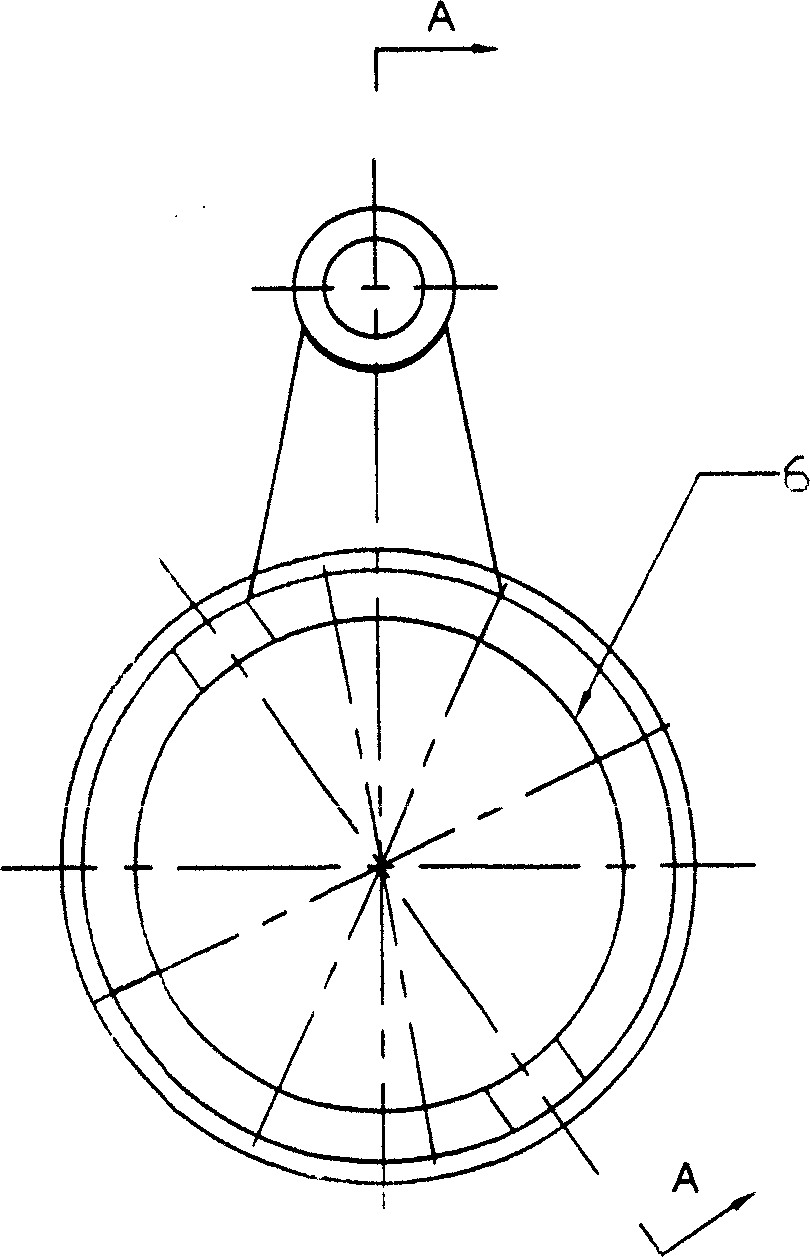

[0046] Figure 23 Shown is a diagram of the connection between the piston type automobile tractor and the hand jack 28, that is, the hand jack is inserted into the hand jack insertion hole 17 of the tailstock 8, and its end section is articulated with the passive vehicle, such as the height of the articulated It is not suitable to adjust by hand jack. Its axial direction is connected with the drawbar 27, ball head 29 of driving car. The operation steps are to pull out the piston safety shaft 15 (Fig. 25), pull up the wrench (Fig. 26) to make the shaft pin 6-1 rotate 90° artificially by the rotating cam assembly 6, and make the shaft pin 6-1 break away from the wrench bracket 18 (Fig. 27 ), the piston body 14 in the traction head 1 retreats simultaneously, and the ball joint 29 connected to the traction rod 27 of the active vehicle is inserted into the inner ball socket of the traction head 1 ( Figure 28 ), then turn the rotary cam assembly 90° counterclockwise ( Figure 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com