Hollow metal pipe twisting formation method

A molding method and metal tube technology, applied in the field of molding, can solve the problems of defective products, trouble, inconvenience of clamping and rotating the square tube 1, etc., and achieve the effect of reducing equipment cost and saving material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The aforementioned and other technical contents, features and effects of the present invention will be clearly understood in the following detailed description of the two preferred embodiments with reference to the accompanying drawings.

[0037] Before presenting a detailed description, it is noted that in the following description, similar elements are denoted by the same reference numerals.

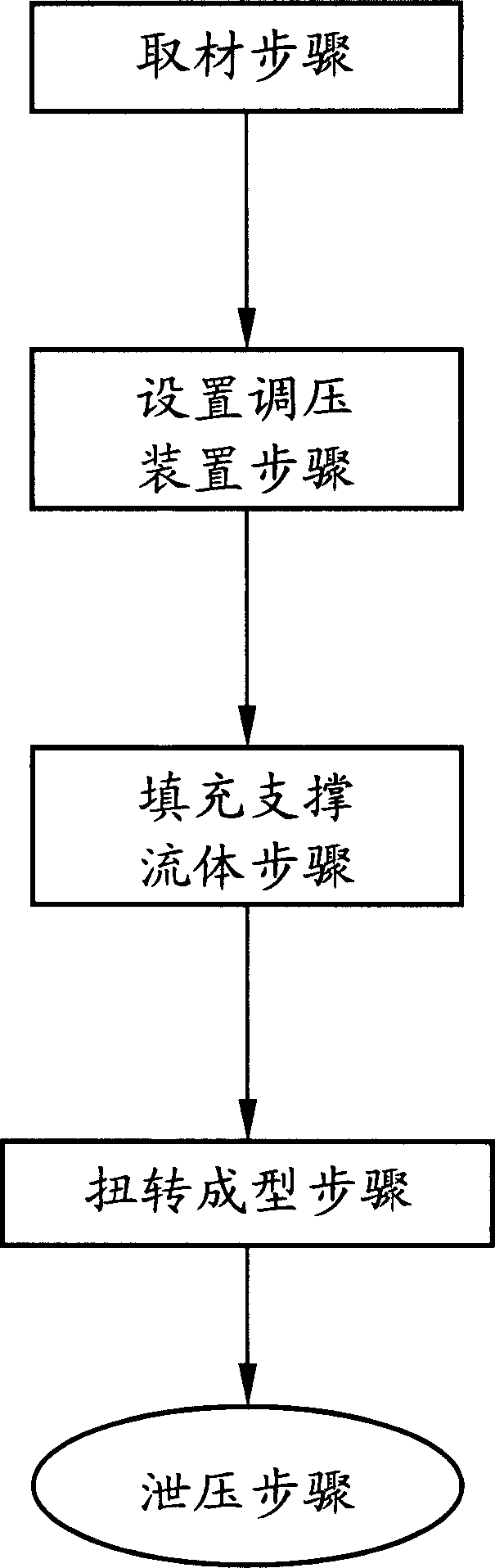

[0038] refer to Figure 4 , is the first preferred embodiment of the twist forming method of the hollow metal tube of the present invention, comprising the following steps:

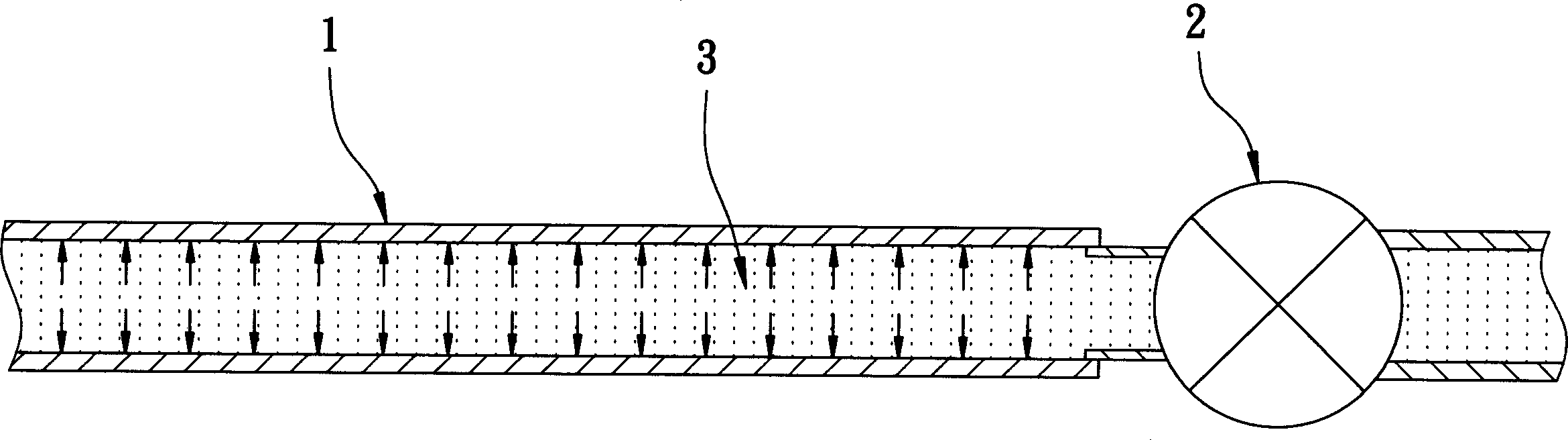

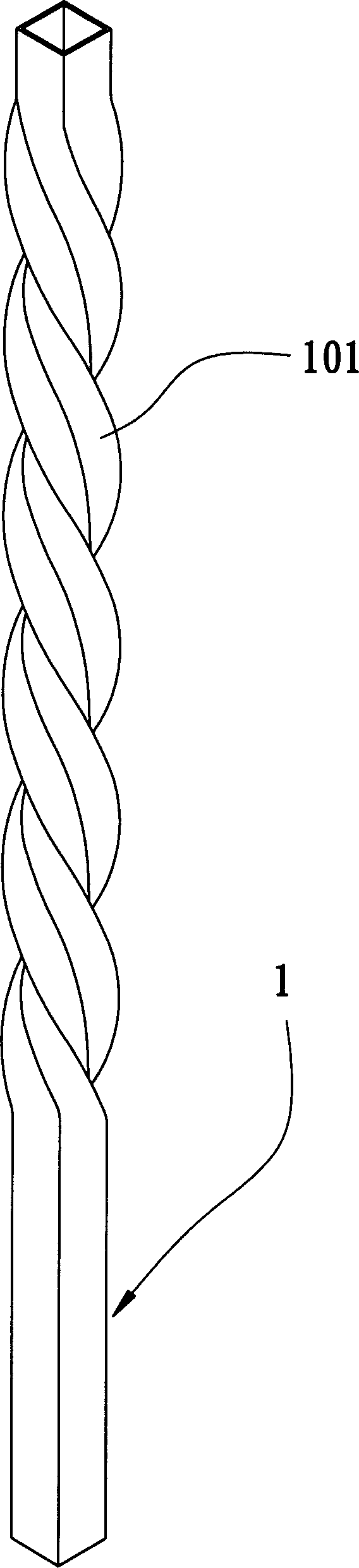

[0039] Step 1: Refer to Figure 5 , 6 , 7. Prepare a hollow metal tube 10 , a solid reinforcing piece 20 , and a twisting machine 30 . The metal pipe 10 has a first positioning section 11, a second positioning section 12, and a pre-torsion section 13 connected between the first and second positioning sections 11, 12 along an axis x, the first positioning section 11 has a first inner hole 111, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com