Directly-discharging low temperature storage tank

An in-line storage tank technology, which is applied to container discharge methods, pressure vessels, container filling methods, etc., can solve the problems of poor cooling effect, rising manufacturing cost of low-temperature storage tanks, and high material prices, achieving complete liquefaction and saving Equipment cost, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

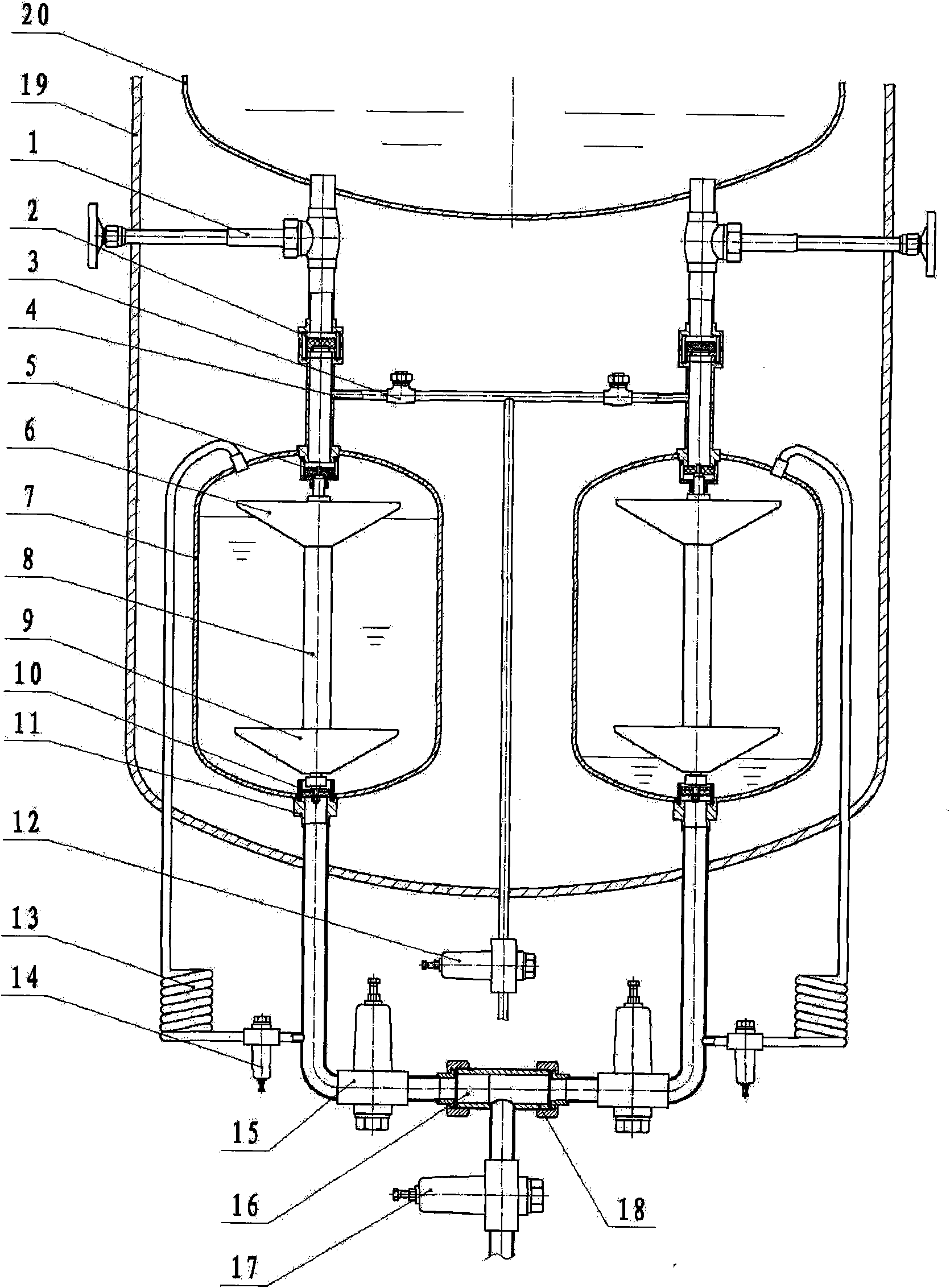

[0007] With reference to the accompanying drawings, it includes a low-temperature storage tank 19, a low-temperature storage tank liner 20 is arranged in the low-temperature storage tank, two pressurized tanks 7 with identical structures are arranged below the low-temperature storage tank liner 20, and the bottom of the low-temperature storage tank liner There are two holes, respectively connected to the main valve 1 of the booster tank on the top of the two booster tanks; There is a check valve 3 and a pressure relief pipe 4 between the one-way valve and the inlet valve of the booster tank. The pressure relief pipes on the upper part of the two booster tanks are connected to the pressure reducing (stabilizing) valve 12 through pipelines. There is a floating valve in the booster tank. Sub 6, lower float 9 and booster tank inlet valve 5, outlet valve 10 form a float assembly. It is connected with the outlet valve, and the outlet valve can slide up and down in the outlet valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com