Railway gondola car loading system

A railway and car loading machine technology, which is applied in the direction of railway car body parts, freight cars, transport passenger cars, etc., can solve the problems of large investment in civil engineering and equipment, loading bulk materials outside the open car, waste of manpower and material resources, etc., to save equipment funds, High loading efficiency, civil construction saving and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

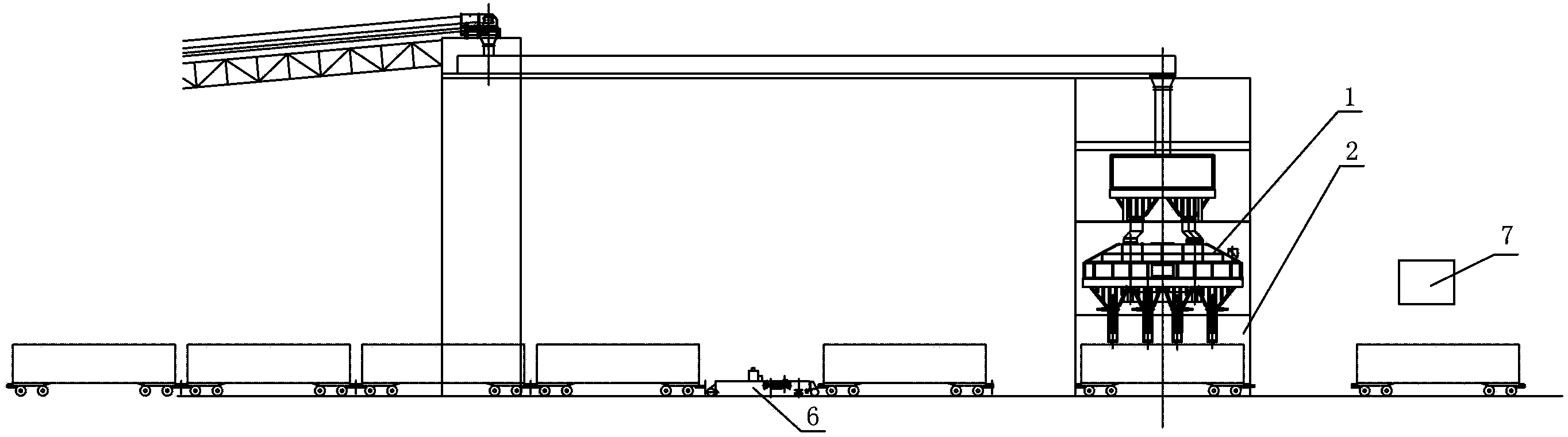

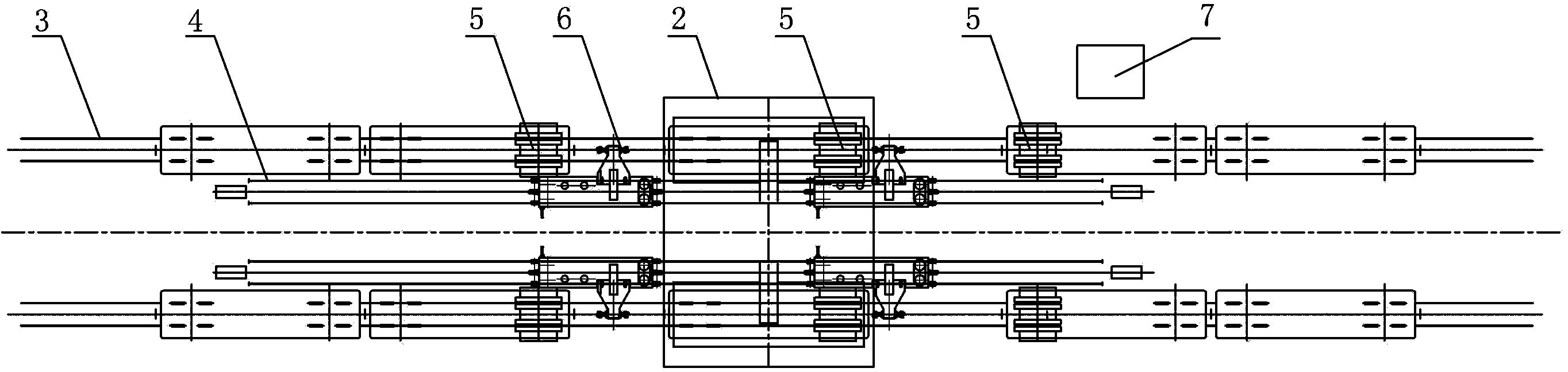

[0037] The specific embodiment of the present invention such as shown in accompanying drawing, is made up of car loading machine 1, car loading building 2, gondola track 3, gondola car fixing device 5; A fixed car loading building 2 is built across the gondola track 3, and car loading machine 1 is installed on the loading building 2, and the gondola car on the gondola track 3 is aligned with the discharge port of the loading machine 1 above; it is characterized in that a gondola car fixing device 5 is installed on the gondola car track 3; The shunting machine track 4 and the shunting machine 6 are free to walk on the shunting machine track 4; the shunting machine 6, the gondola car fixing device 5 and the loading machine 1 are connected with the PLC control system 7 for automatic control of the whole frequency conversion speed regulation.

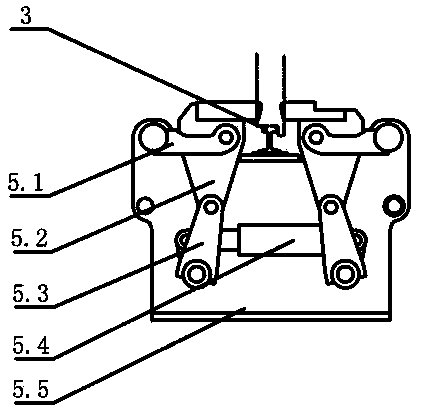

[0038] Gondola car fixing device 5 is contained in the gondola car loading waiting area of loading building 2 one sides, loading area in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com