Device and method for checking printed circuit board power source isolation

A technology of printed circuit boards and inspection devices, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

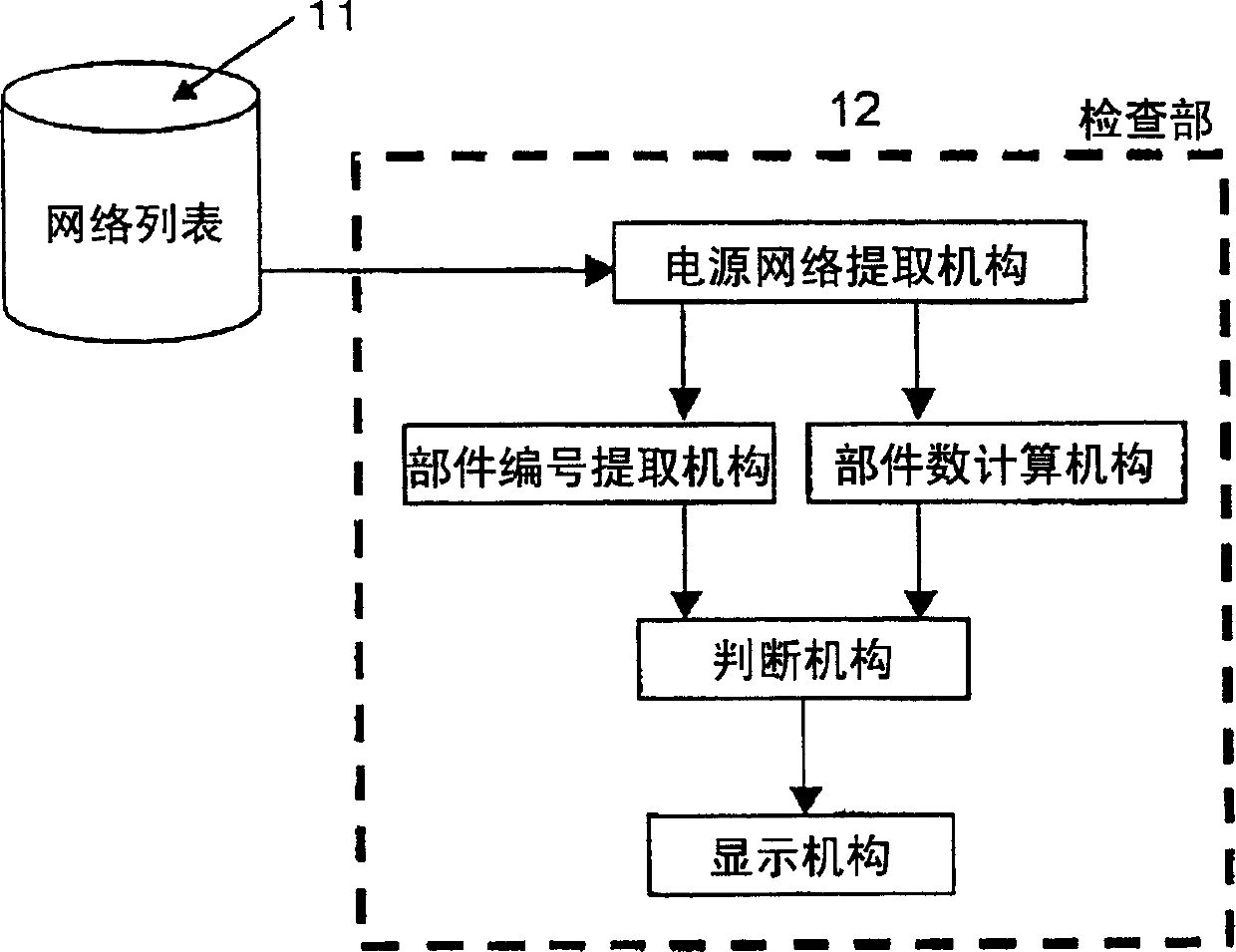

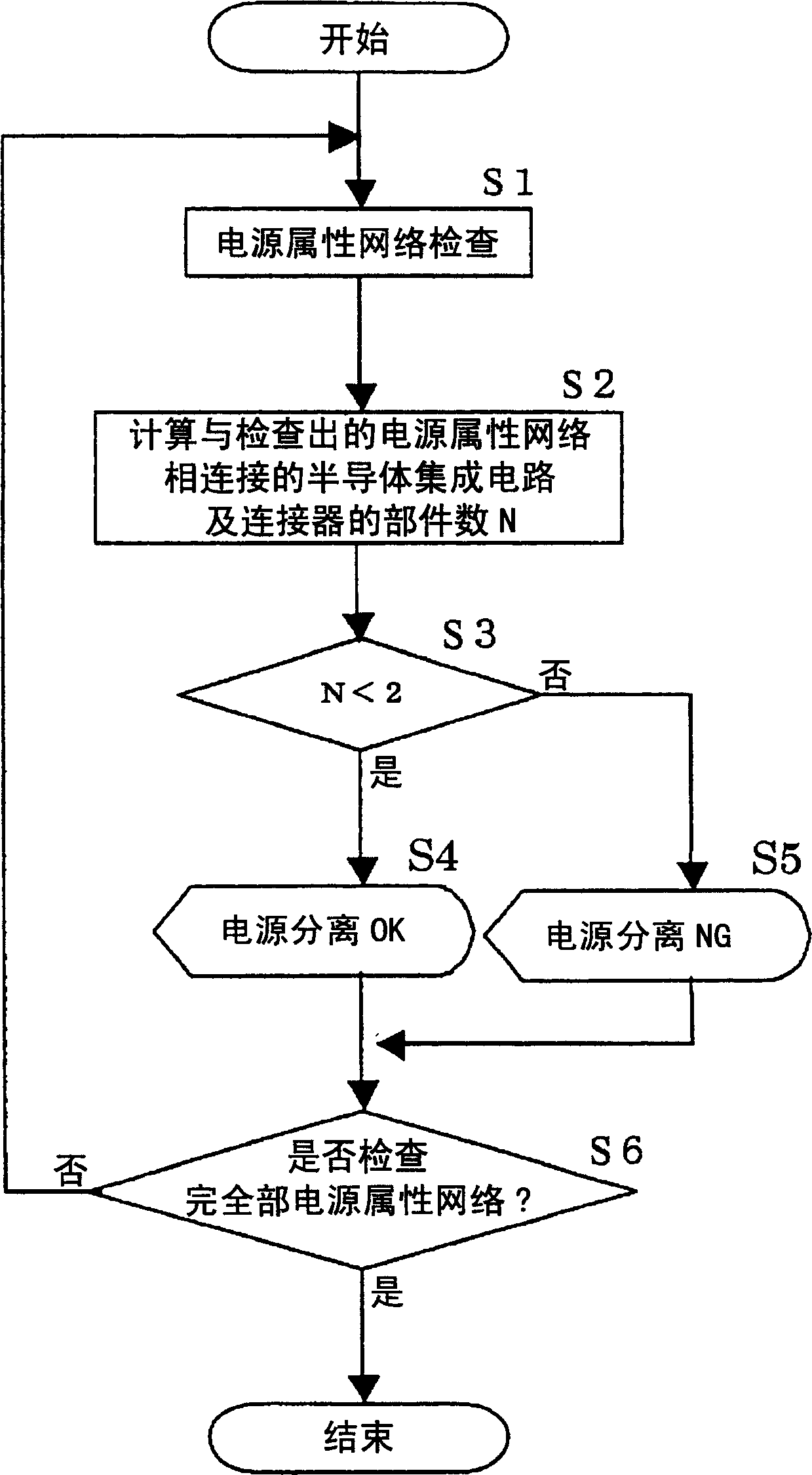

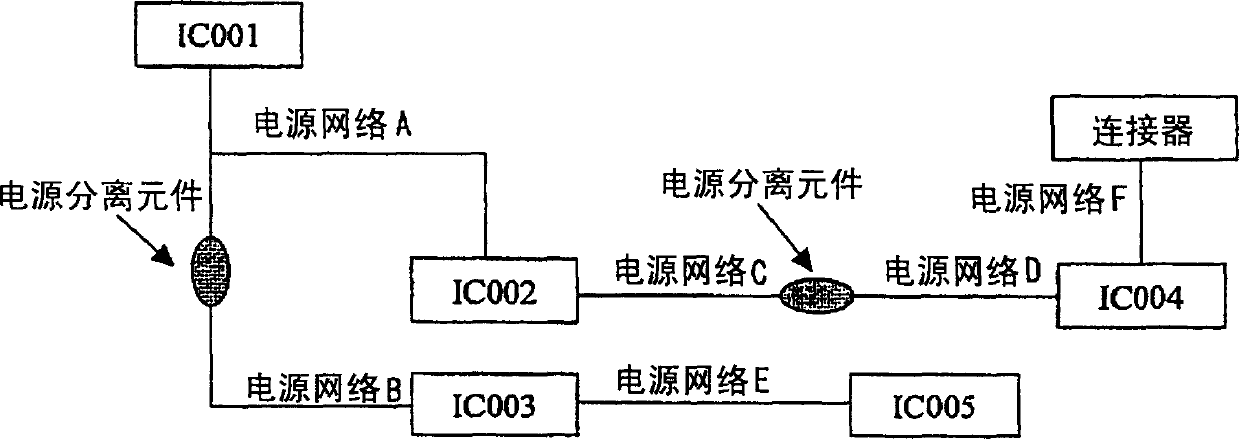

[0036] FIG. 1 is a functional block diagram showing the configuration of the first embodiment of the present invention. The printed circuit board power isolation inspection device includes an inspection unit 12 for judging the power isolation state of the printed circuit board by referring to the circuit design data of the printed circuit board stored in the net list unit 11 of the data storage device or the like.

[0037] The inspection unit 12 can be composed of a computer including an arithmetic processor, various hardware and various software, etc. Functionally, it includes a power supply network extraction mechanism, a part number extraction mechanism, a component number calculation mechanism, a judgment mechanism, and a display mechanism.

[0038] The power supply net extraction means refers to the power supply nets of the power supply attribute that are classified by the power supply separation elements with reference to the circuit design data of the printed circuit boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com