Process for producing filmy optical waveguide

A technology of optical waveguide and optical waveguide parts, which is applied in the coupling of optical waveguide, optical waveguide light guide, light guide, etc., can solve the problem that the light incident end surface and the light exit end surface cannot have smoothness, and achieve the effect of efficient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

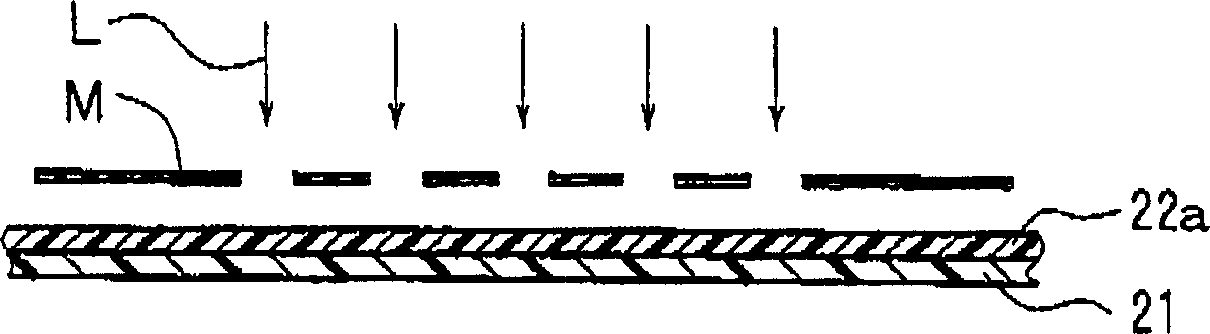

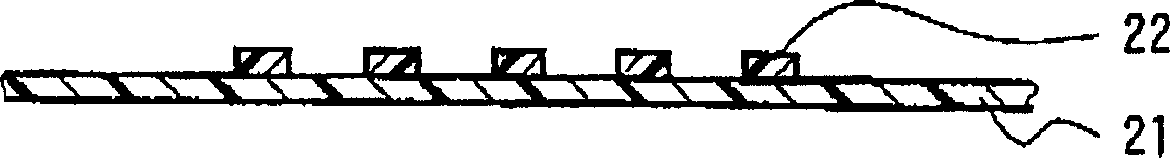

[0047] Manufactured in the manner shown below as Figure 5 The thin film structure shown, then fabricates an optical waveguide in the manner shown below.

[0048] Fabrication of Thin Film Structures

[0049] A strip-shaped epoxy resin film (250 mm in width; 30 m in length; 30 μm in thickness; 1.55 in refractive index) was prepared for use as an under cladding layer. A core layer having a predetermined pattern (line width 50 μm; height 50 μm; refractive index 1.62) was formed from a photosensitive epoxy resin in a region where an optical waveguide was to be formed in the resin film. Next, a liquid epoxy resin was applied onto the core layer and then cured to form an upper cladding layer (thickness 30 μm; refractive index 1.55). In this way, a strip-shaped thin film structure (thickness 150 µm) having an optical waveguide formed therein was produced.

[0050] Optical waveguide formation

[0051] Subsequently, the individual optical waveguide members in the film structure...

example 2

[0057] Fabrication of Thin Film Structures

[0058] A strip-shaped fluorinated epoxy resin film (250 mm in width; 30 m in length; 20 μm in thickness; 1.51 in refractive index) was prepared for use as an under cladding layer. A region in the resin film where the optical waveguide is to be formed is formed of a photosensitive polyimide resin with a predetermined pattern of a core layer (line width 8 μm; height 8 μm; refractive index 1.54). Next, a polyamic acid solution (polyimide resin precursor solution) is applied to the core layer, and then imidized to form an upper cladding layer (thickness 20 μm; refractive index) made of polyimide resin. rate 1.51). In this way, a strip-shaped thin film structure (thickness 48 µm) having an optical waveguide formed therein was manufactured.

[0059] Optical waveguide formation

[0060] An optical waveguide was obtained in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com