Conveying method and apparatus for cables to be assembled

A technology for conveying equipment and cables, applied in circuits, electrical components, line/collector parts, etc., and can solve the problems of cable end oscillation, swinging motion, trouble, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

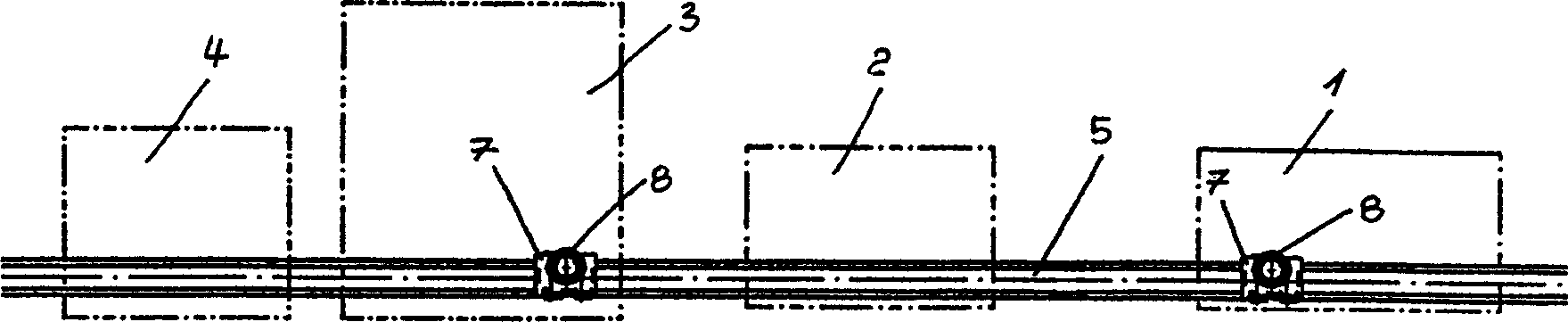

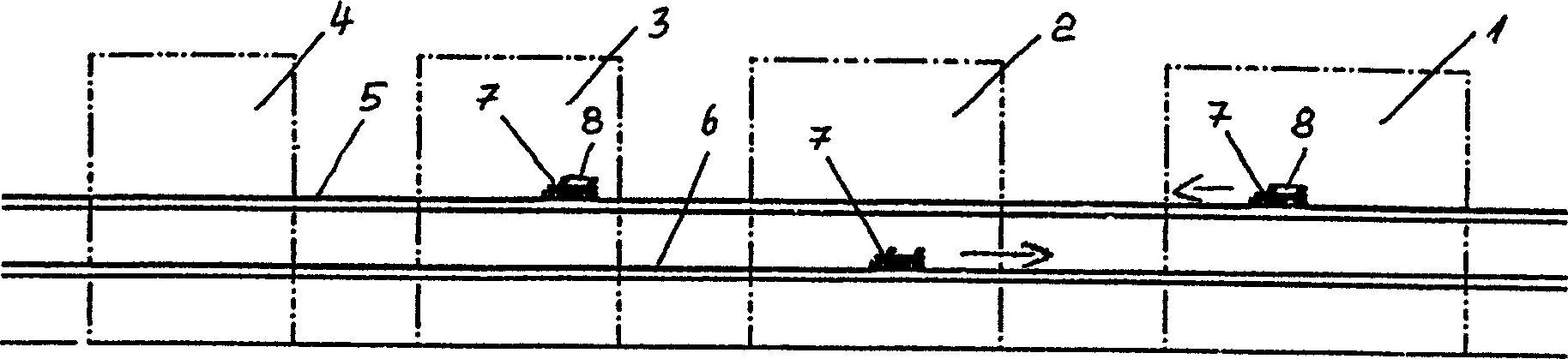

[0015] figure 1 and figure 2 The processing stations 1-4 set up for fitting the ends of the mounted cables are shown one by one. In this way, for example, the stripping of the cable ends and the stretching of the cable cores can be carried out at station 1, the installation of plug-in strips or pins can be carried out at station 2, the crimping can be carried out at station 3 and continued if necessary The necessary stripping is carried out, and the final installation is carried out in certain cases at the station 4 .

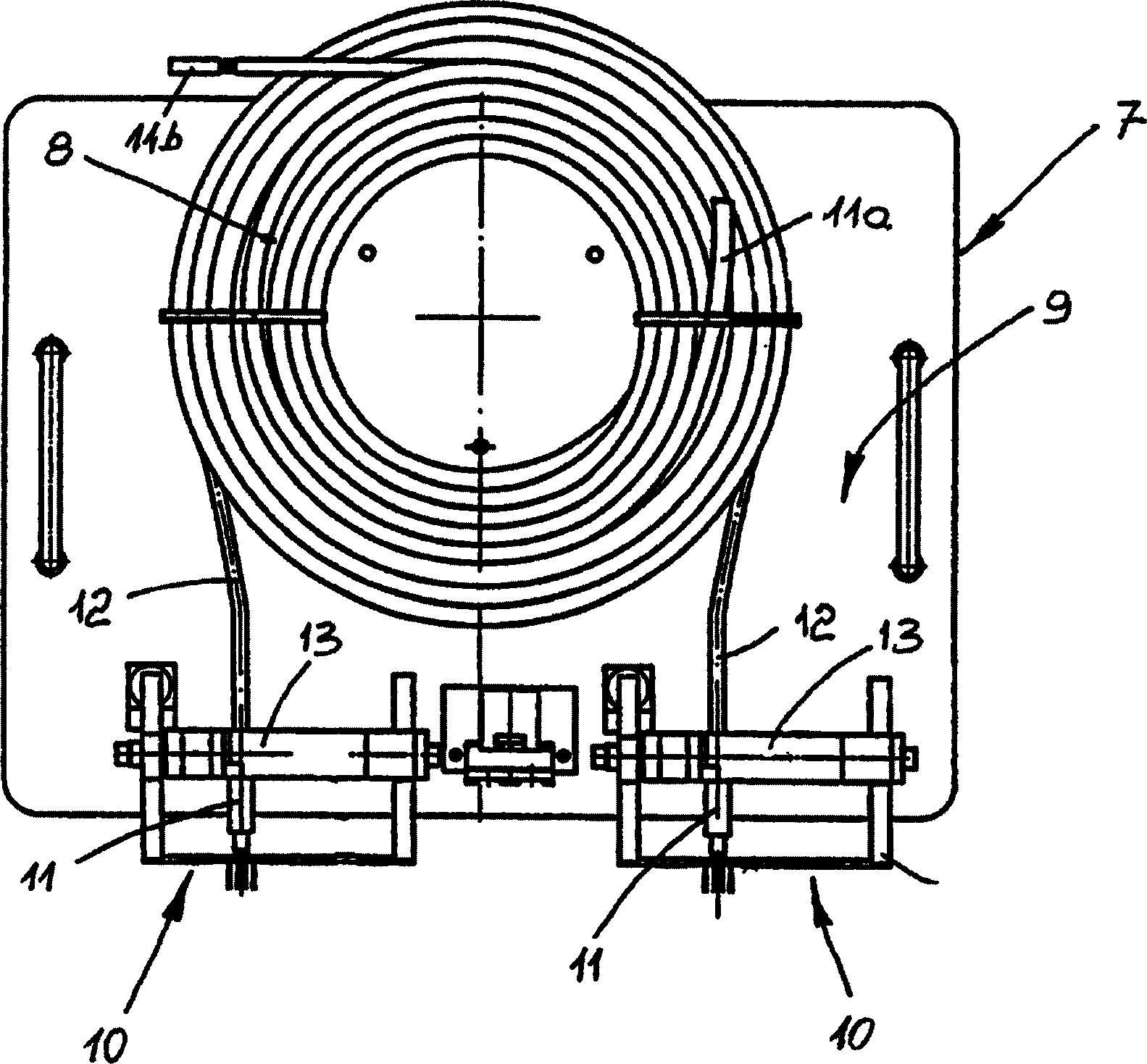

[0016] Along the processing stations 1-4, there is provided a conveying device 5, 6 consisting of a continuous endless chain or a continuous endless conveyor belt. The upper return section 5 and the lower return section 6 of the conveying devices 5, 6 are arranged above the lower return section in the vertical direction. On the upper return section 5, the follow-up pallet 7 is conveyed along the processing stations 1-4, and the follow-up pallet 7 is loaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com