Multifunction sliding bearing experimental platform

A technology of sliding bearings and test benches, which is applied in the direction of mechanical bearing testing, etc., and can solve problems such as the absence of sliding bearing test benches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

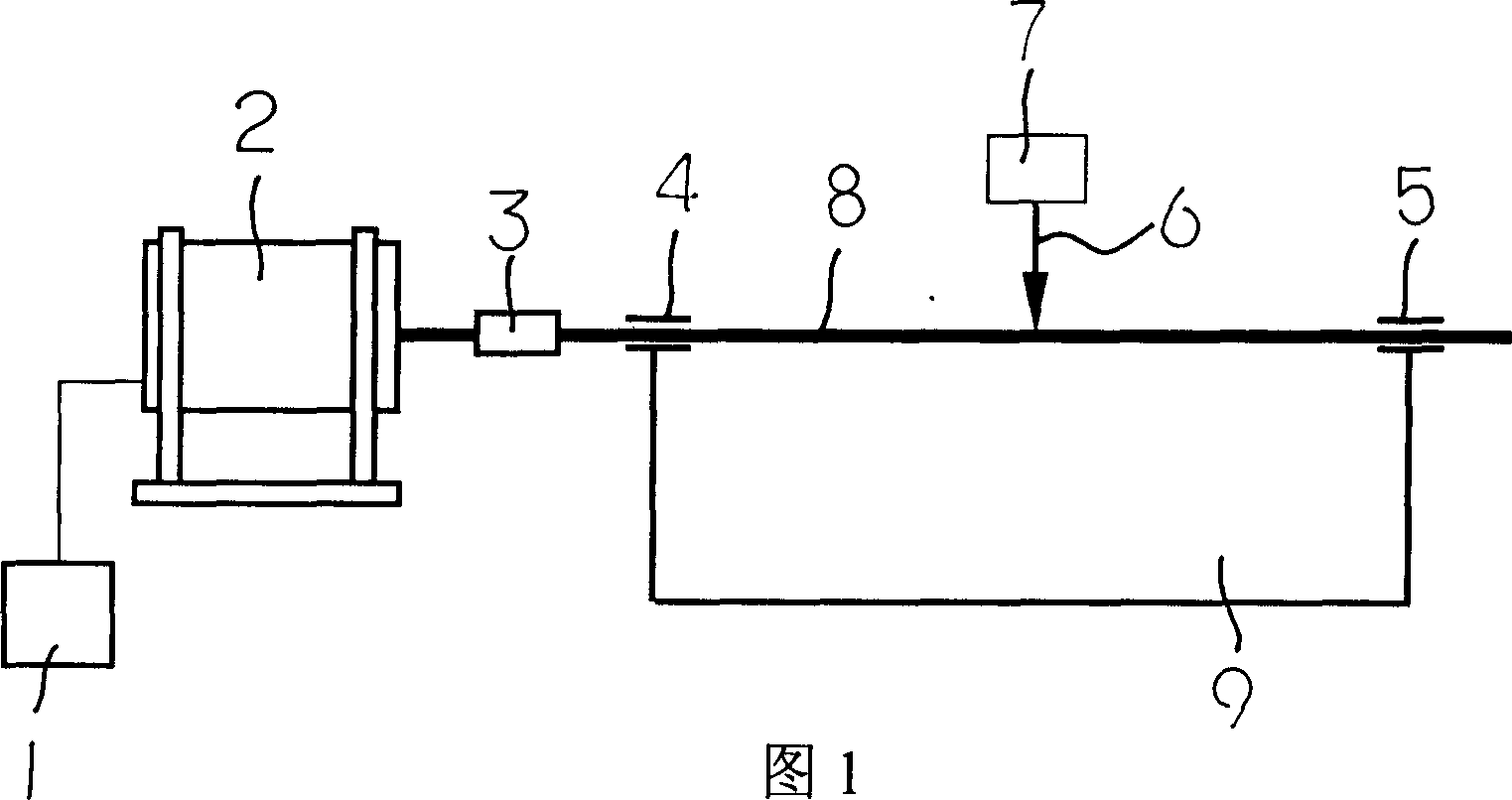

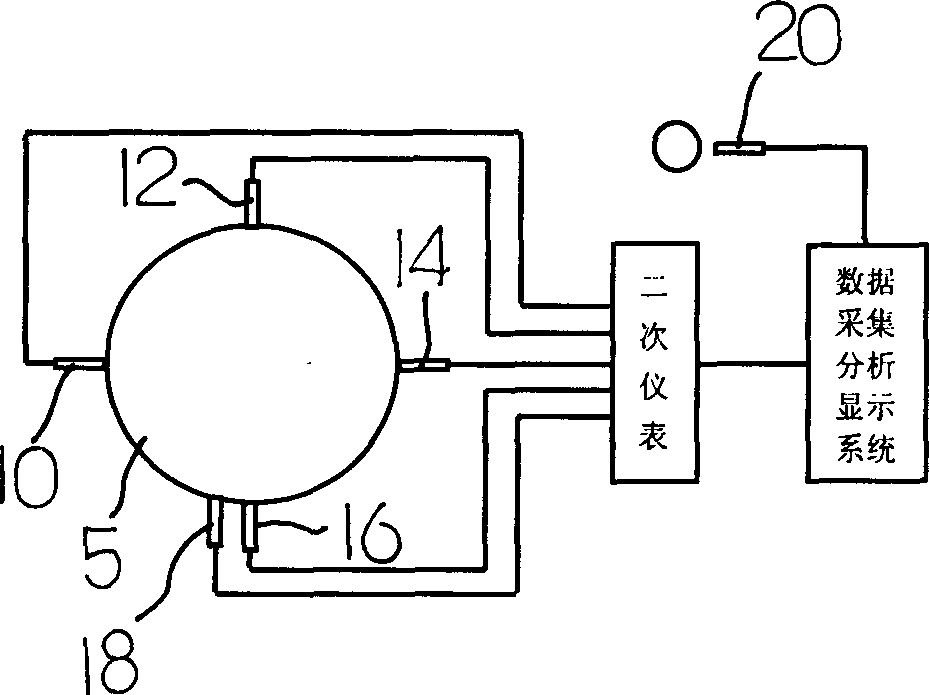

[0033] As shown in Figure 1, the motor 2 provides a speed of 0-5000r / min, drives the main shaft 8 to rotate through the coupling 3, and the speed is regulated by the frequency converter 1. The two ends of the main shaft 8 are supported by the bearing 4 and the tested bearing 5, and the bearing 4 and the tested bearing 5 are installed in the coaxial hole of the box 9; the load 6 is generated by the load controller 7 and applied to the center or both sides of the main shaft 8. On the side, the stiffness (deformation) of the main shaft and the influence of dynamics on the sliding bearing are generated. The load can be static load or dynamic load. The load is controlled by the computer, and the size and frequency of the change can be randomly changed; the lubricating oil is supplied by the electric pump Station supply, the lubricating oil passes through the oil supply pump of the electric pump station, then injects into the bearing through the oil supply hole of the bearing, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com