Cleaning method for pre-processing

A secondary water washing and working state technology, applied in the field of pre-treatment cleaning, can solve the problems of coating film shrinkage, easy generation of static electricity, sticking dust, etc., achieve high stability and improve the effect of cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] The present invention is described in further detail below with reference to the accompanying drawings in conjunction with examples:

[0019] For the pretreatment cleaning method, the cleaning principle used will be described first:

[0020] The oil stains on the surface of the workpiece to be cleaned are wetted, softened and separated under the action of the physical and chemical forces of heat energy and detergent and the mechanical force of the water jet of the cleaning machine. The force leads to the crushing, peeling and falling off of the dirt layer. When the cleaning fluid flows along the workpiece, the dirt particles are taken away, so as to achieve the purpose of cleaning.

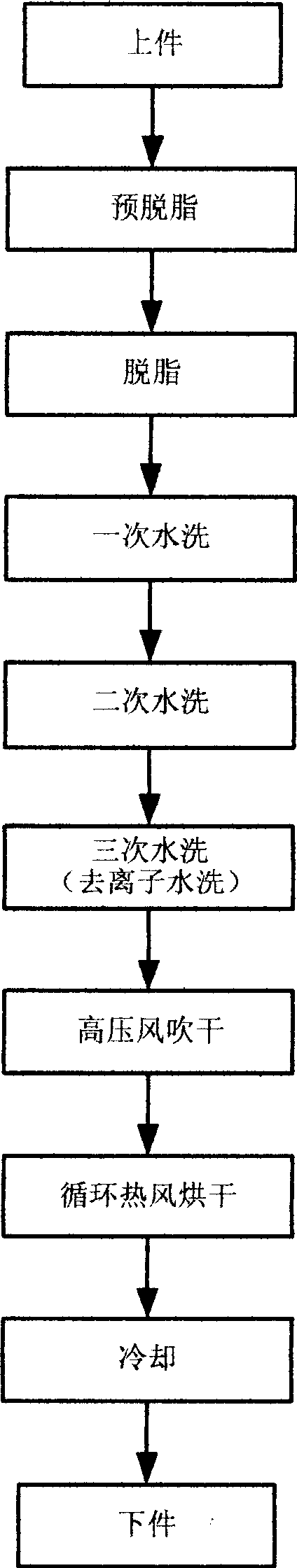

[0021] This principle is common in the industry, but how to optimize the arrangement and maximize the work efficiency to make the process arrangement more scientific and reasonable is the content to be disclosed by a pretreatment cleaning method of the present invention. see figure 1 , th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap