Manual valve of automatic transmission

A manual valve and slide valve technology, applied in the field of manual valves, can solve the problems of lubricating oil affecting shifting feeling and slowing lubricating oil flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

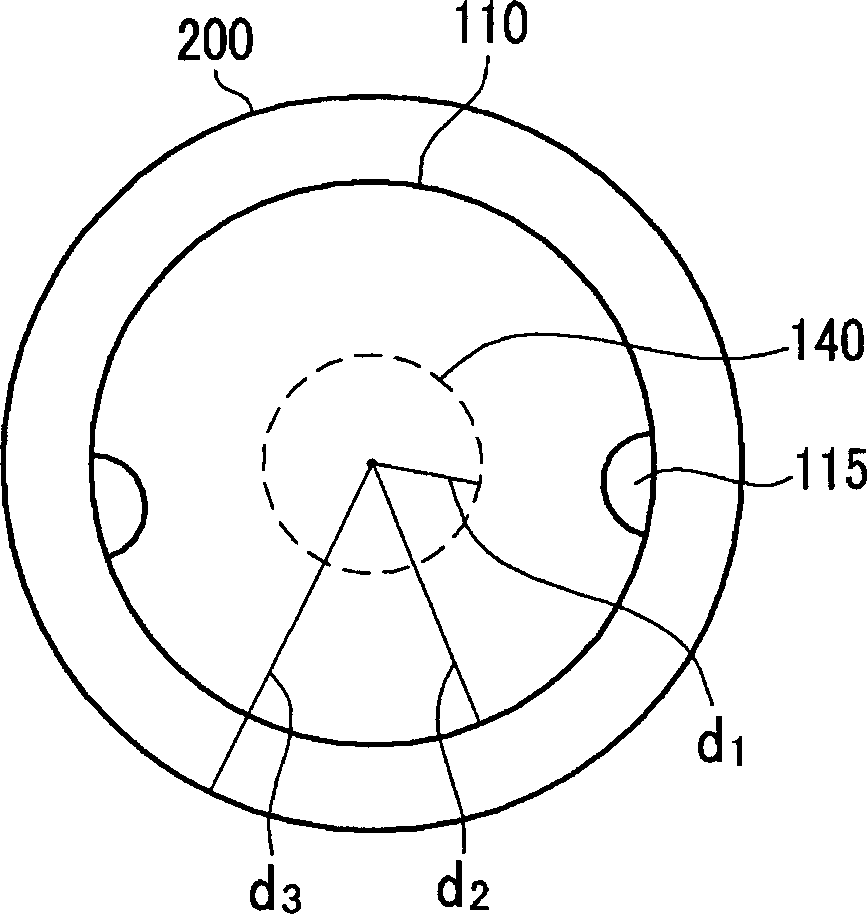

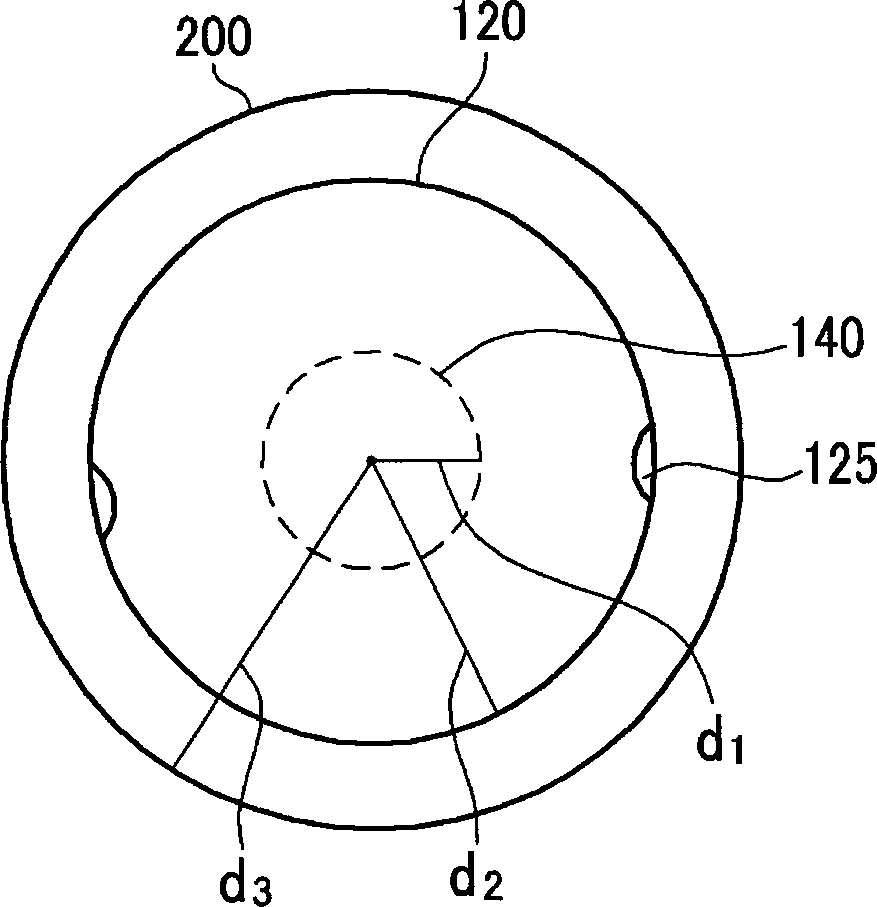

[0048] A manual valve according to an exemplary embodiment of the present invention includes a valve body 200 and a spool valve 100 .

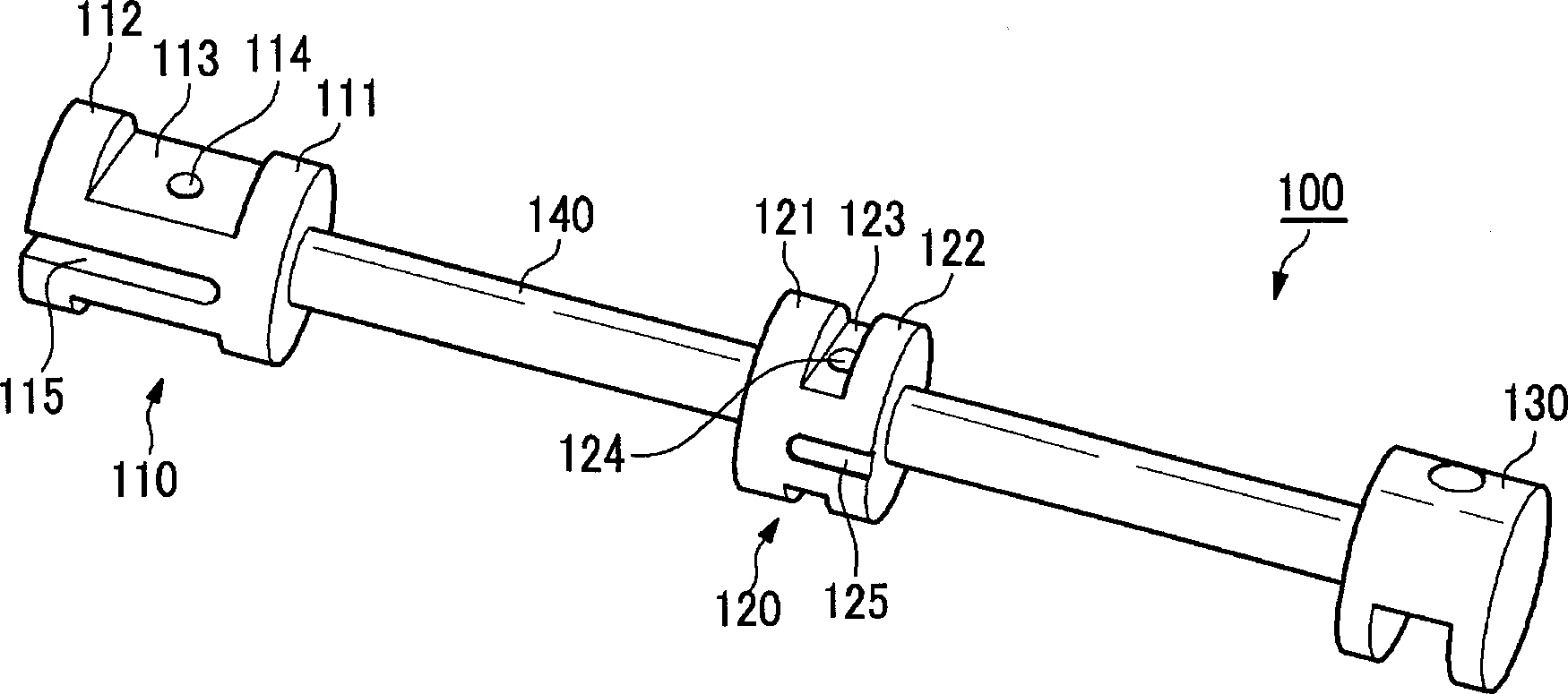

[0049] Below, refer to Figure 1 to Figure 3 , the structure of the slide valve 100 according to the exemplary embodiment of the present invention will be described in detail.

[0050] The spool valve 100 according to the exemplary embodiment of the present invention includes a central shaft 140, a lower transmission boss assembly 110 formed at one end of the central shaft 140, a connector formed at the other end of the central shaft 140 and connected with a shift control lever. 130, and the reversing boss assembly 120 formed between the lower transmission boss assembly 110 and the connector 130.

[0051] The lower transmission boss assembly 110 includes a first boss 111 and a second boss 112 that are cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com