Siding boards attachment structure

A technology of structure and siding, applied in the direction of building structure, covering/lining, construction, etc., can solve the problems of reduced appearance design, easy cracks on outer siding, and reduced construction efficiency, etc., and achieve the effect of superior constructability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

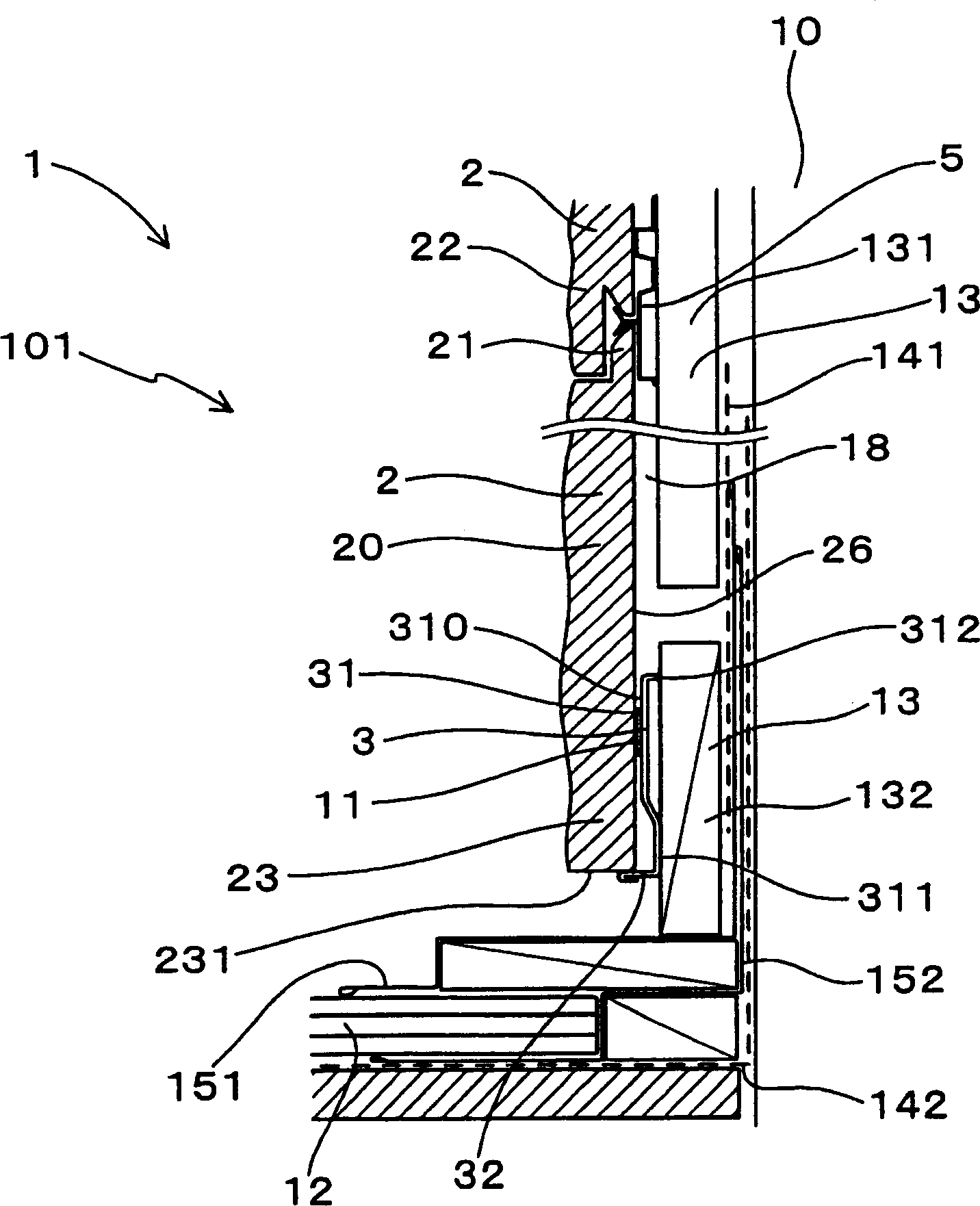

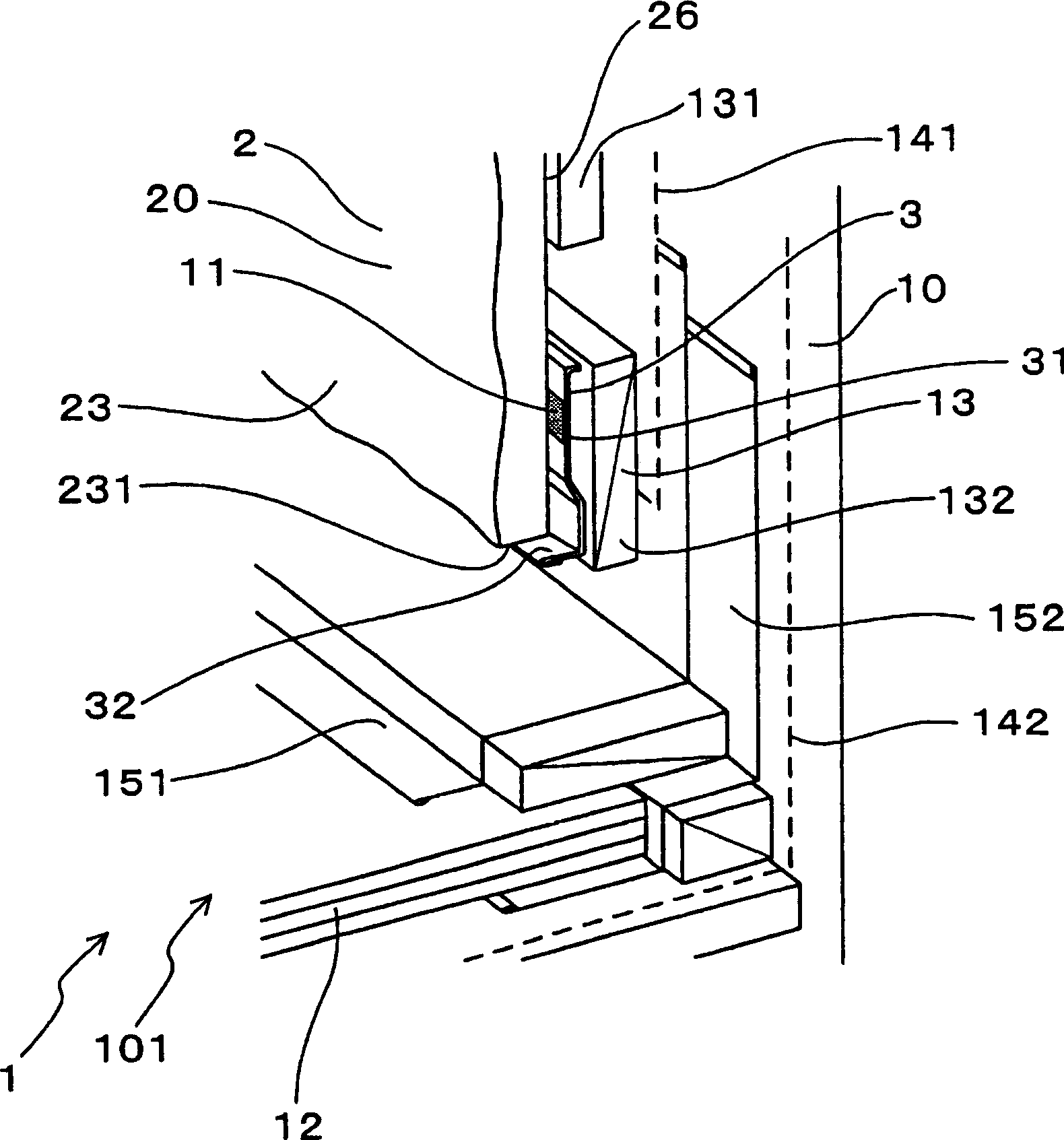

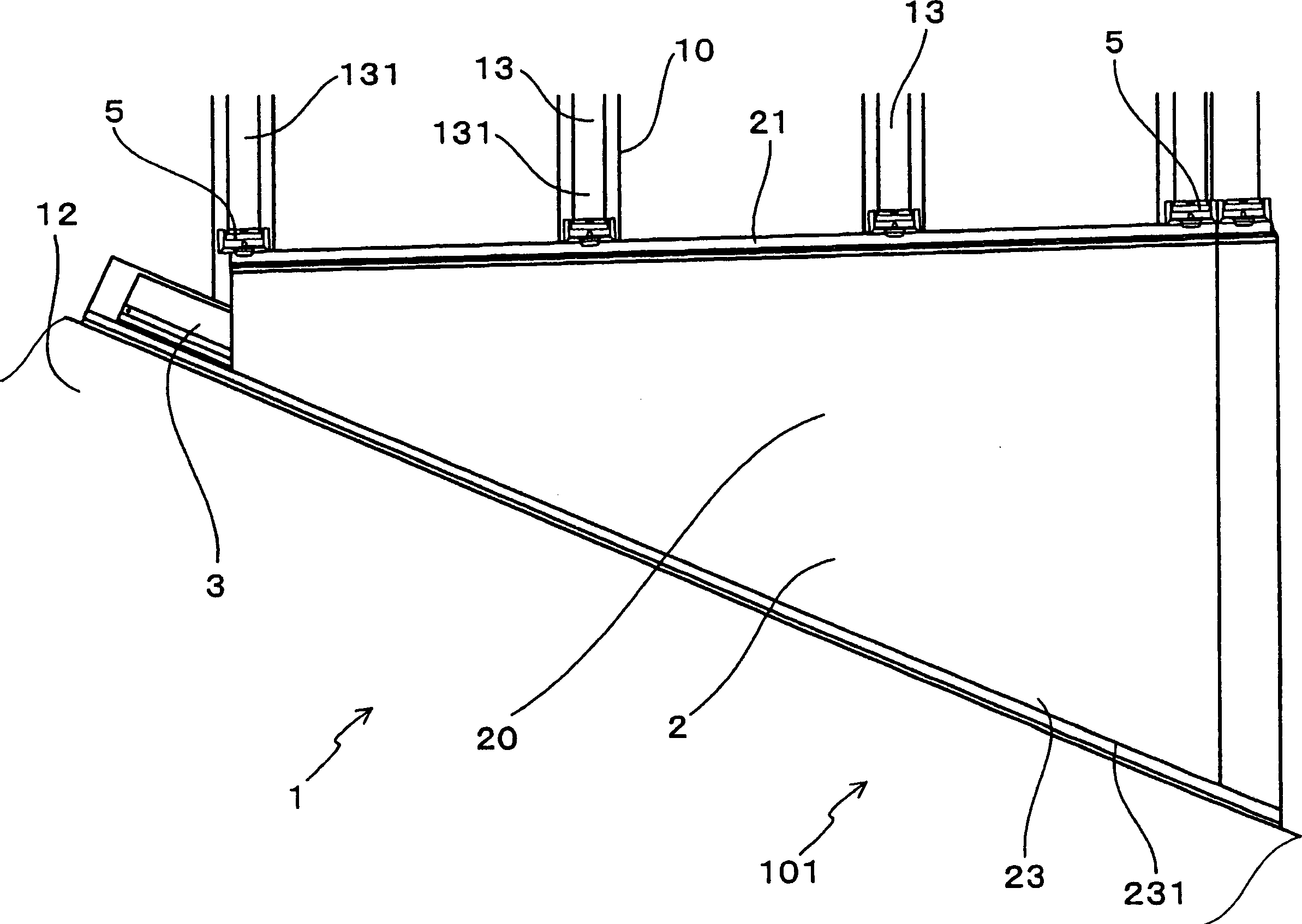

[0057] use Figure 1 to Figure 6 The outer wall construction structure of the embodiment of the present invention will be described.

[0058] The outer wall construction structure 1 of the present embodiment, such as figure 1 , Figure 4 As shown, a plurality of outer wall panels 2 are spliced up and down and joined, and at the same time, they are fixed on the structural body 10 of the building by the stop metal piece 5 .

[0059] In the state where the upper lower wedge 21 formed on the upper side of the outer wall panel 2 arranged on the lower side and the lower upper wedge 22 formed on the lower side of the outer wall panel 2 arranged on the upper side are locked, the stop metal fitting 5 is fixed to the structure. Body 10 on.

[0060] Such as Figure 1 ~ Figure 3 As shown, among the above-mentioned plurality of outer wall panels 2 , the lower upper wedge 22 is cut off from the size adjustment outer wall panel 20 having the truncated end portion 23 which cuts off the...

Embodiment 2

[0090] Such as Figure 7 , Figure 8 As shown, the present embodiment is an example of the outer wall construction structure 1 of the joint portion 102 on the beam side of the lower roof 12 .

[0091] That is, the end portion construction metal fitting 3 is disposed on the cut-off end portion 23 of the size-adjusting outer wall panel 20 disposed on the above-mentioned joint portion 102 .

[0092] In this embodiment, a front waterproof paper 141 and a piece of flashing 15 and a rear waterproof paper 142 are interposed between the battens 13 and the construction body 10 .

[0093] Others are the same as in Embodiment 1.

[0094]In the case of this embodiment, the design and weather resistance of the joint portion 102 on the beam side that is jointed with the lower roof 12 can be improved.

[0095] In addition, it has the same effect as Example 1.

Embodiment 3

[0097] Such as Figure 9 , Figure 10 As shown, this embodiment is an example of the outer wall construction structure 1 on the upper side of the opening 16 where windows and the like are arranged.

[0098] That is, the end portion construction metal fitting 3 is disposed on the cut-off end portion 23 of the dimension adjustment outer wall panel 20 disposed above the opening portion 16 .

[0099] In addition, a window frame 161 is disposed above the opening 16 , and above the window frame 161 , the horizontal slats 132 and the size-adjusting outer wall plate 20 are disposed. The size adjustment outer wall panel 20 is cut along the shape of the opening 102 , and the cut end 23 is arranged on the upper side of the opening 102 .

[0100] In addition, the end part construction metal fitting 3 is arrange|positioned at this cut-off end part 23. As shown in FIG.

[0101] In addition, a sealing material 163 is driven between the cut-off end portion 23 and the window frame 161 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com