Process for the hydrolysis of starch

A starch hydrolysis and starch technology, applied in biofuels, fermentation, etc., can solve problems such as energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

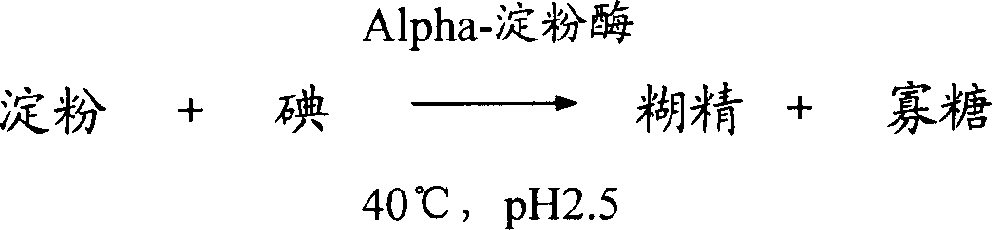

Image

Examples

Embodiment approach

[0058] The starch slurry subjected to the treatment of the present invention may have 20-55% dry solids granular starch, preferably 25-40% dry solids granular starch, more preferably 30-35% dry solids granular starch.

[0059] After treatment according to the first aspect of the present invention, at least 85%, at least 86%, at least 87%, at least 88%, at least 89%, at least 90%, at least 91%, at least 92%, at least 93%, at least 94% %, at least 95%, at least 96%, at least 97%, at least 98% or preferably at least 99% of the dry solids of the granular starch are converted to soluble starch hydrolysates.

[0060] According to the invention, the treatments of the first and second aspects are carried out at a temperature below the initial gelation temperature. Preferably, said treatment is carried out at a temperature of at least 30°C, at least 31°C, at least 32°C, at least 33°C, at least 34°C, at least 35°C, at least 36°C, at least 37°C, at least 38°C, at least 39°C, At least 40...

Embodiment 1

[0110] This example illustrates the conversion of granular wheat starch to glucose using the bacterial four-component alpha-amylase and glucoamylase and acid fungal amylase. A slurry of 33% dry solids (DS) granular starch was prepared by adding 247.5 g of wheat starch to 502.5 ml of water with stirring. The pH was adjusted to 4.5 with HCl. The granulated starch slurry was dispensed into 100 ml blue capped shake flasks, 75 g per shake flask. The shake flask was incubated in a 60°C water bath with magnetic stirring. At 0 hours, the enzyme activities set forth in Table 1 were dosed into the shake flasks. Samples were taken after 24, 48, 72 and 96 hours.

[0111] bacterial alpha-amylase

[0112] The total dry solid starch should be determined by the following method. The starch was completely hydrolyzed by adding excess alpha-amylase (300 KNU / Kg dry solids) and placing the sample in an oil bath at 95° C. for 45 minutes. The samples were then cooled to 60°C, and exce...

Embodiment 2

[0117] This example illustrates the partial conversion of granular starch to glucose using glucoamylase and acid fungal amylase.

[0118] Shake flasks containing 33% DS granular starch were prepared and incubated as described in Example 1. At 0 hours, the enzyme activities set forth in Table 4 were dosed into the shake flasks. Samples were taken after 24, 48, 72 and 96 hours. The samples were analyzed as described in Example 1. The results are shown in Table 5 and Table 6.

[0119] Glucoamylase

[0120] 24 hours

[0121] 24 hours

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap