Heat insulating acoustical structure and carbody shell structure using the same

A technology of structure and sound-absorbing materials, which is applied in the direction of upper structure, vehicle parts, upper structure sub-assembly, etc., and can solve the problems of outsourcing container and heartwood deformation and sinking, heartwood deformation, and heat insulation performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

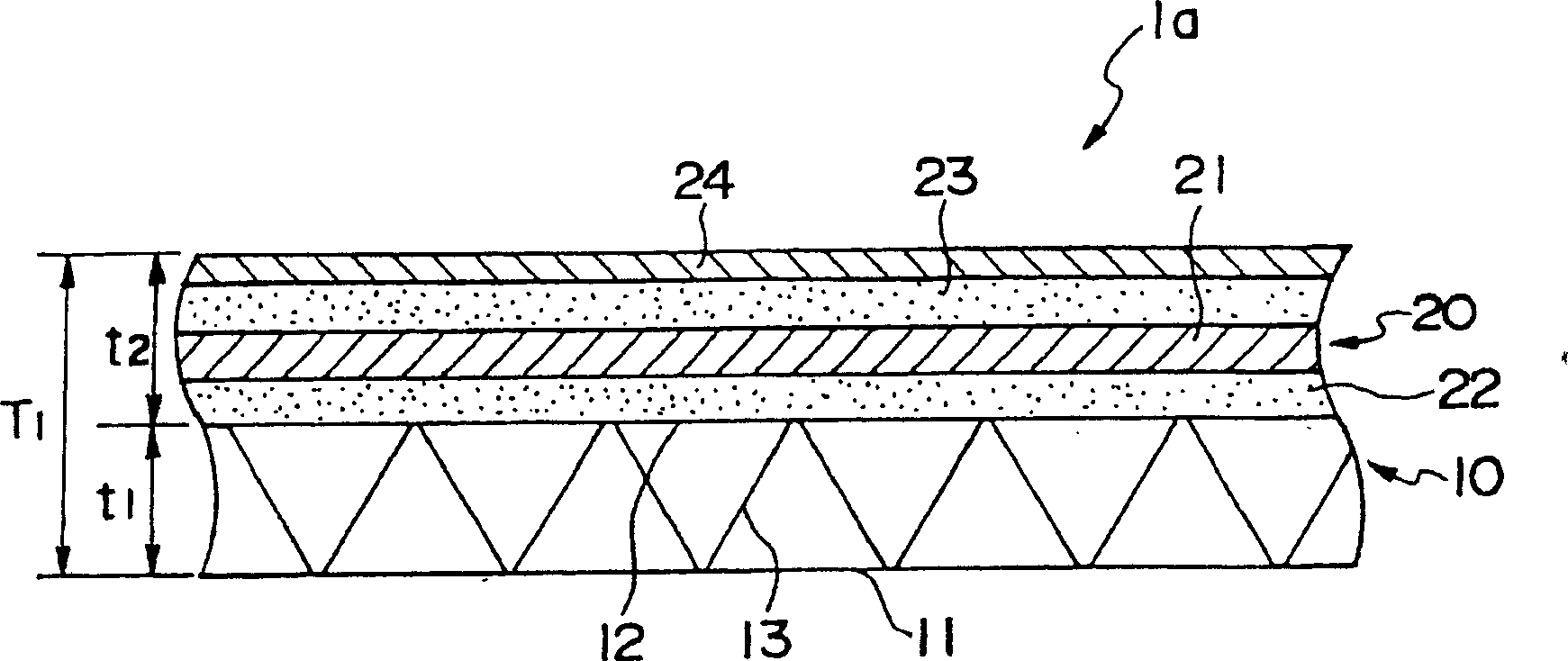

[0023] figure 1 A cross-sectional structure of a heat insulating and sound absorbing structure according to a first embodiment of the present invention is shown. The overall heat-insulating and sound-absorbing structure represented by reference numeral 1 a includes: a heavy-skin structure 10 ;

[0024] The heavy-skin structure 10 is, for example, a profile manufactured by extruding an aluminum alloy, and has a cross-sectional structure in which two parallel plates 11 and 12 are connected by ribs 13 of a framework structure.

[0025] The heat-insulating and sound-absorbing layer 20 is provided on the vehicle inner side of the heavy-skin structure 10, and has elastic sound-absorbing materials 22 and 23 formed of fibrous non-woven fabrics or foams sandwiched between both sides of the vacuum insulation panel 21. Structure. That is, the sound absorbing material 22 , the vacuum insulation panel 21 , and the sound absorbing material 23 are sequentially stacked on the vehicle inner ...

Embodiment 2

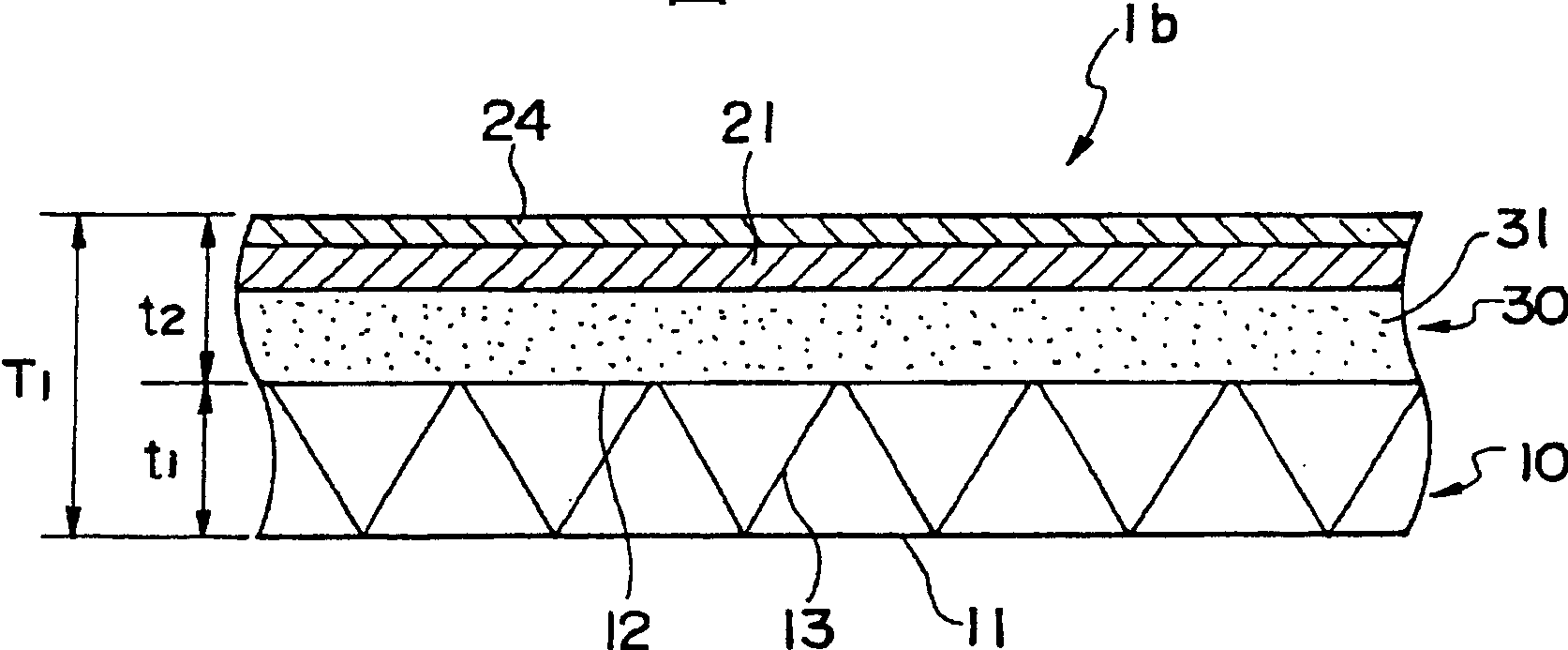

[0049] figure 2 represents another embodiment of the present invention. In the heat-insulating and sound-absorbing structure 1b of the present embodiment, the position where the vacuum insulation panel 21 is provided directly under the interior panel 24 is provided. The sound absorbing material 31 is made of the same material as the fibrous nonwoven fabric 22 used in Example 1. FIG. The thickness dimension is 16mm. The vacuum heat insulating material 21, the inner panel 24, and the heavy skin structure 10 are all the same as those of the first embodiment.

[0050] The thickness dimension t of the heavy skin structure 1 It is 40 mm as in Example 1, and the thickness dimension of the sound-absorbing layer 30 is 24 mm as in Example 1.

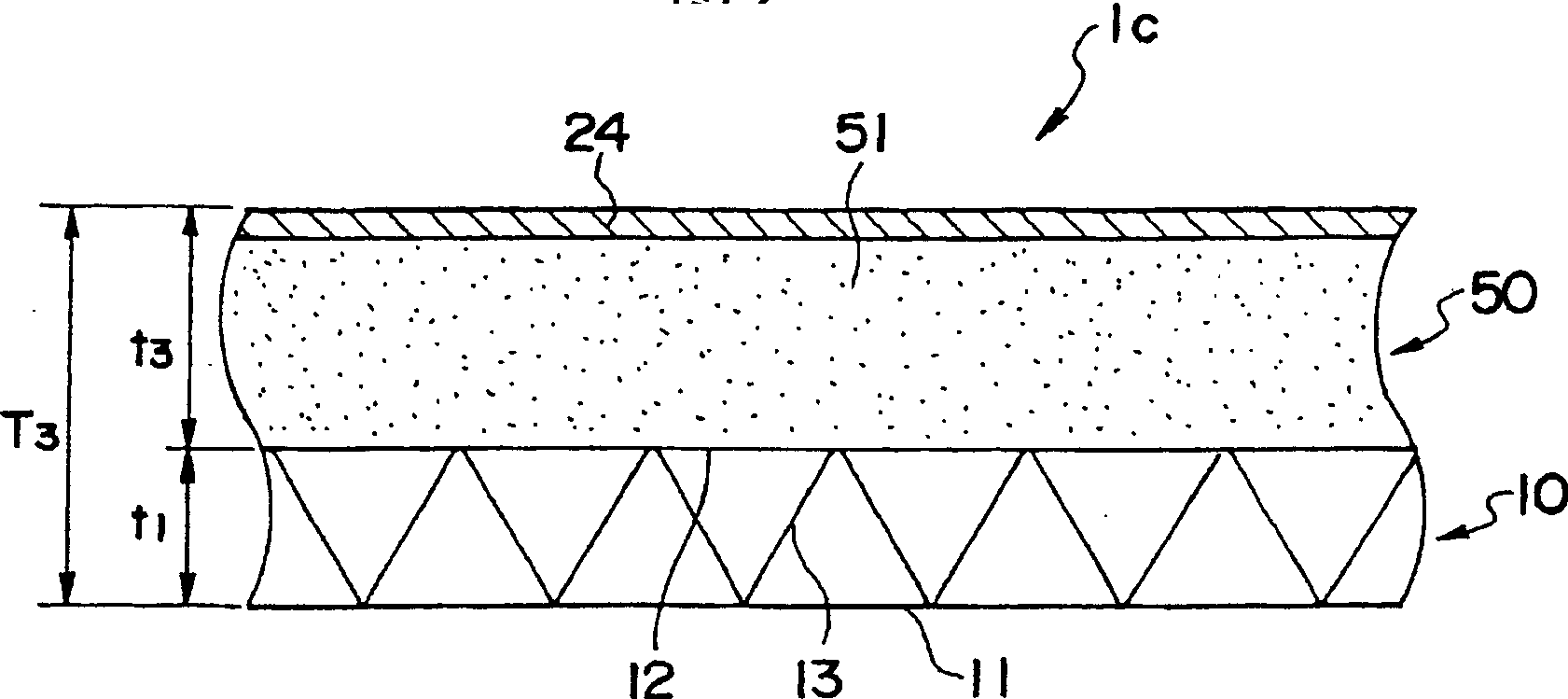

[0051] As a comparison object, use the comparison model's image 3 The sound transmission loss was measured with the test piece of the same size.

[0052] The result is in Figure 6 Indicated. It can be seen from the figure that regardles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness dimension | aaaaa | aaaaa |

| Thickness dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com