Plug seat

A socket and insert technology, applied in the direction of contact parts, fixed/insulated contact members, etc., can solve the problem of shell thickness (height becomes larger, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

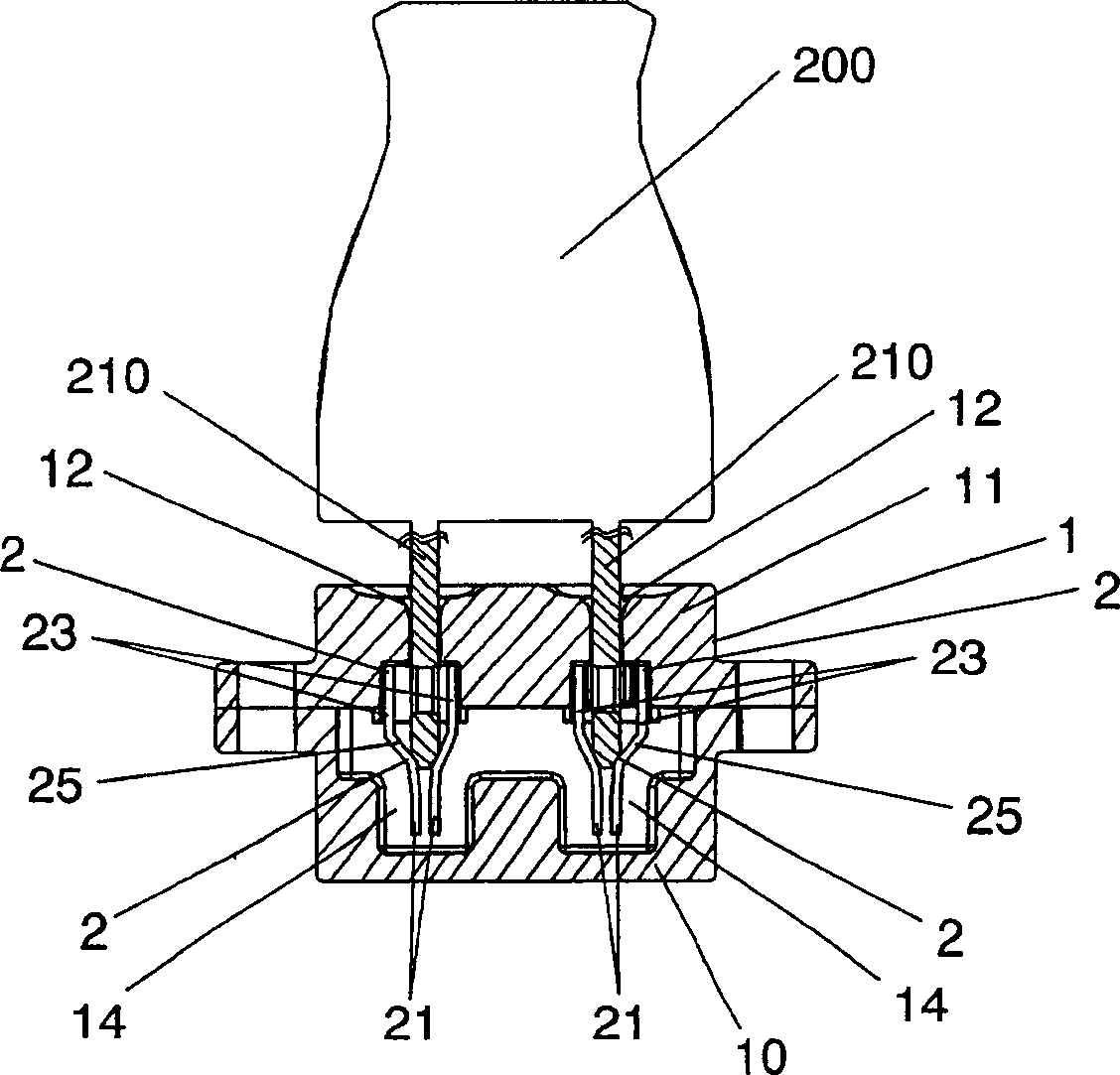

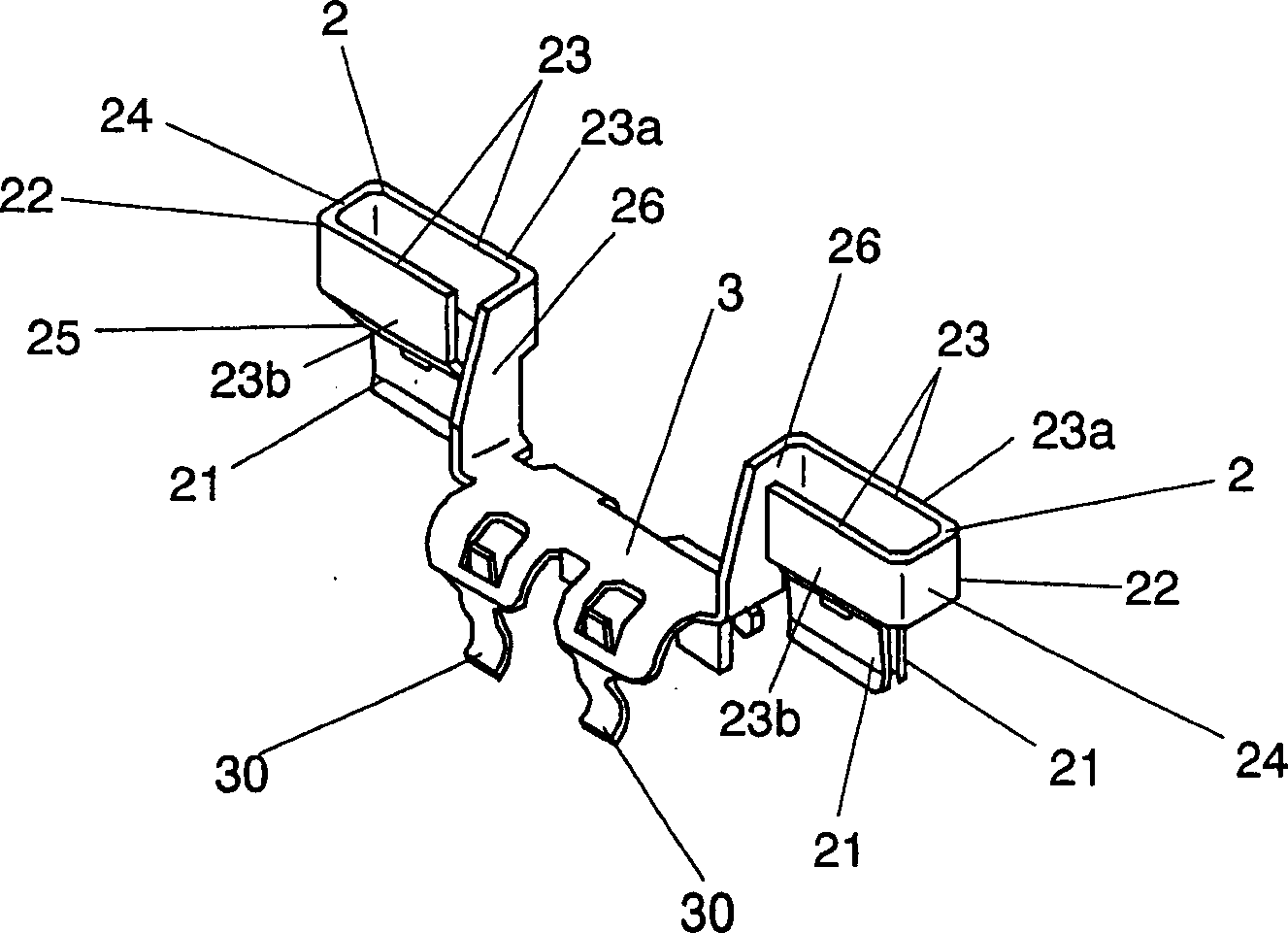

[0058] The socket according to the first embodiment of the present invention is a wall socket installed in a wall with its front surface exposed to the outside. Such as figure 1 As shown, the socket includes: a housing 1, which has two paired slots 12 on its front surface, for inserting the flat insert 210 of the plug 200; and the insert accommodation reed 2, which is installed in the housing , used to accommodate the flat insert inserted into the housing 1 from the slot 12, and electrically connected to the wires (not shown) extending from the outside.

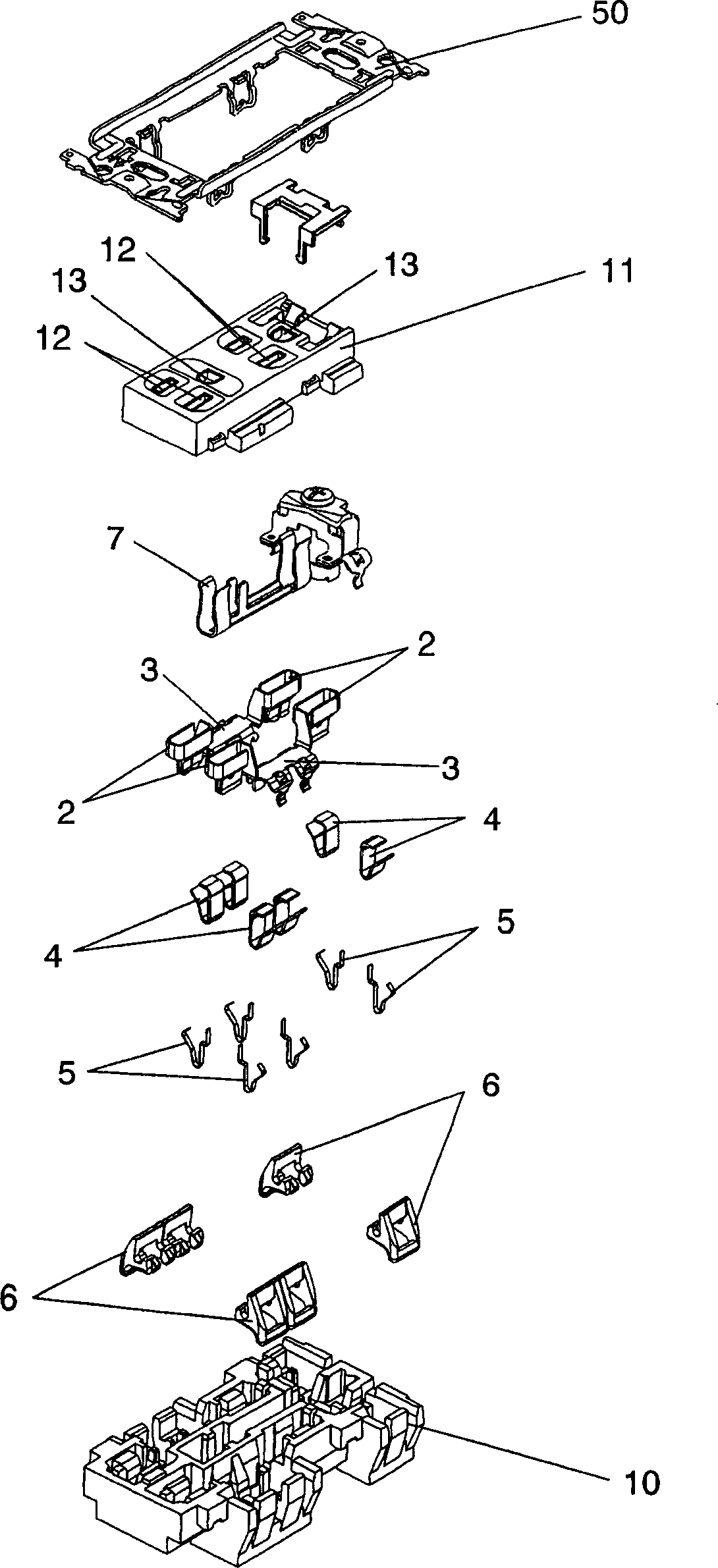

[0059] Such as figure 2 As shown, the housing 1 has an open front surface (in figure 2 The plastic box-type main body 10 of the upper surface in), and the plastic cover plate 11 that covers the front surface of the main body 10 and has a slot 12 on its front surface. The main body 10 and the cover plate 11 are connected to each other by an assembly frame 50 which also serves as an installation frame for installing the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com