Pipe bender

A bending processing and bending technology, which is applied in the field of pipe bending processing equipment, can solve problems such as troublesome and incapable of manufacturing accuracy, and achieve the effects of good operability, realizing feeding operation time, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described below based on the embodiments shown in the drawings.

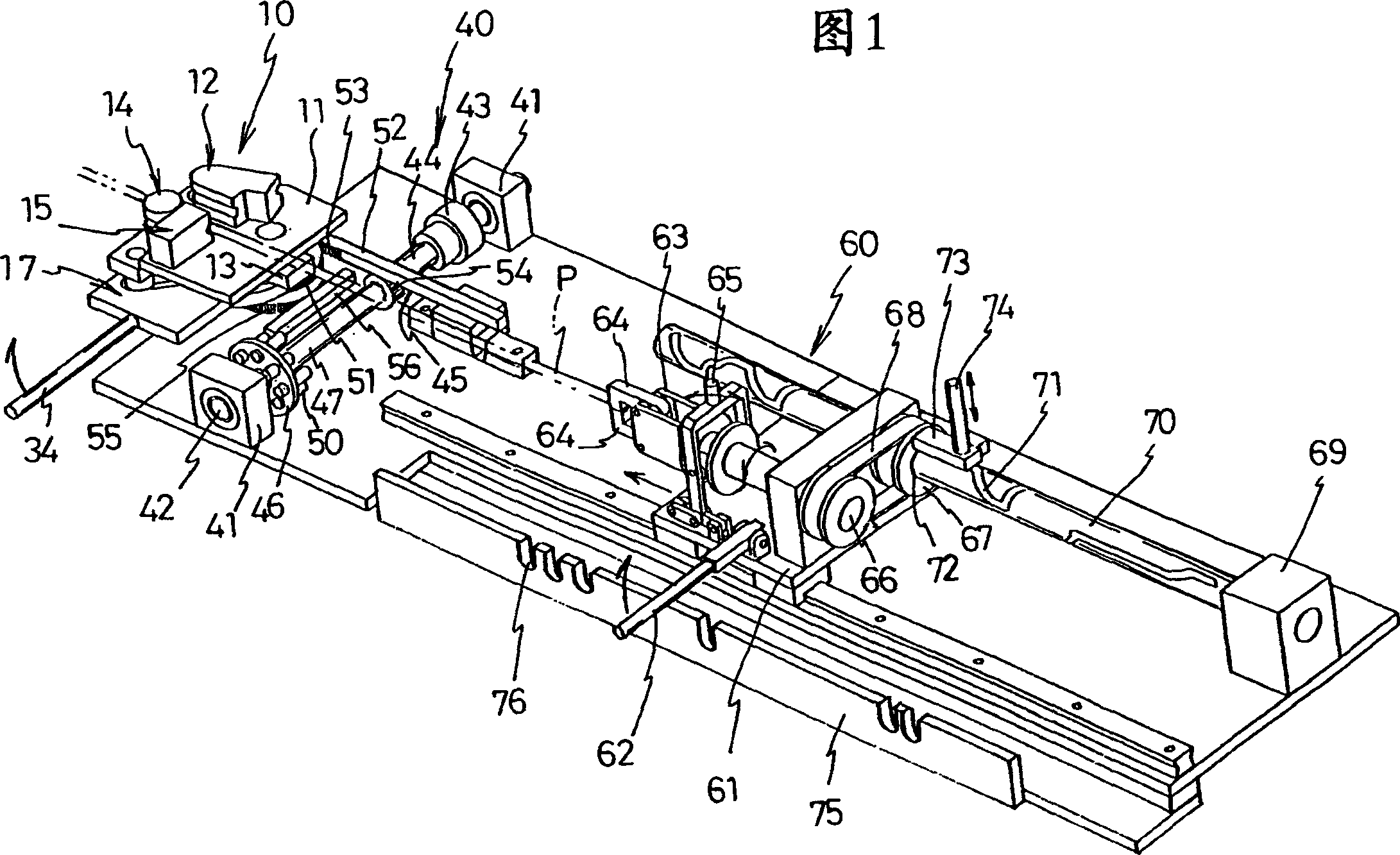

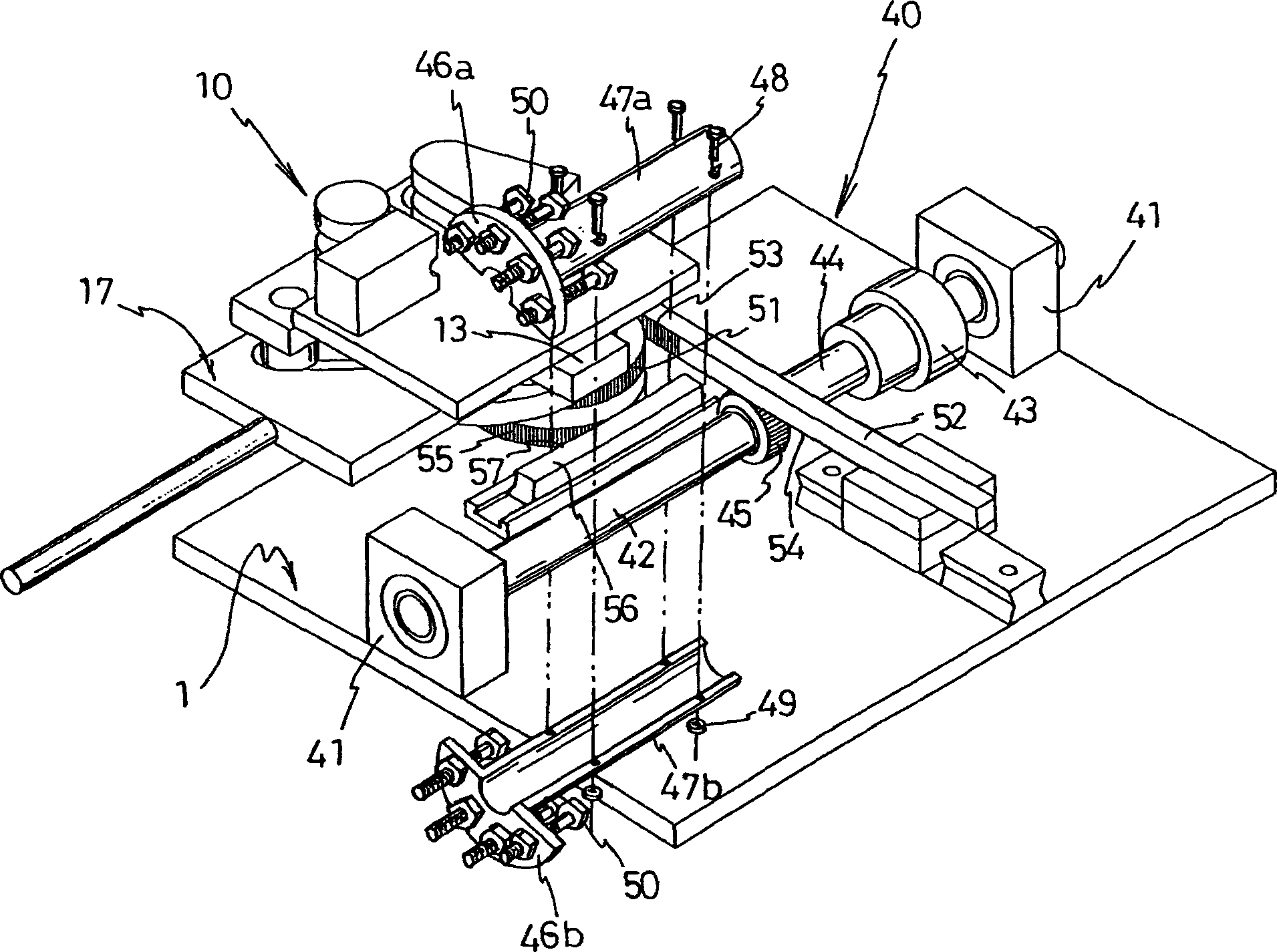

[0048] As shown in FIG. 1 , this pipe bending device includes: a bending unit 10 for bending a pipe, a bending angle setting unit 40 for determining the bending angle of the pipe, and a device for determining the feeding amount and bending direction of the pipe. The feed unit 60 and the like.

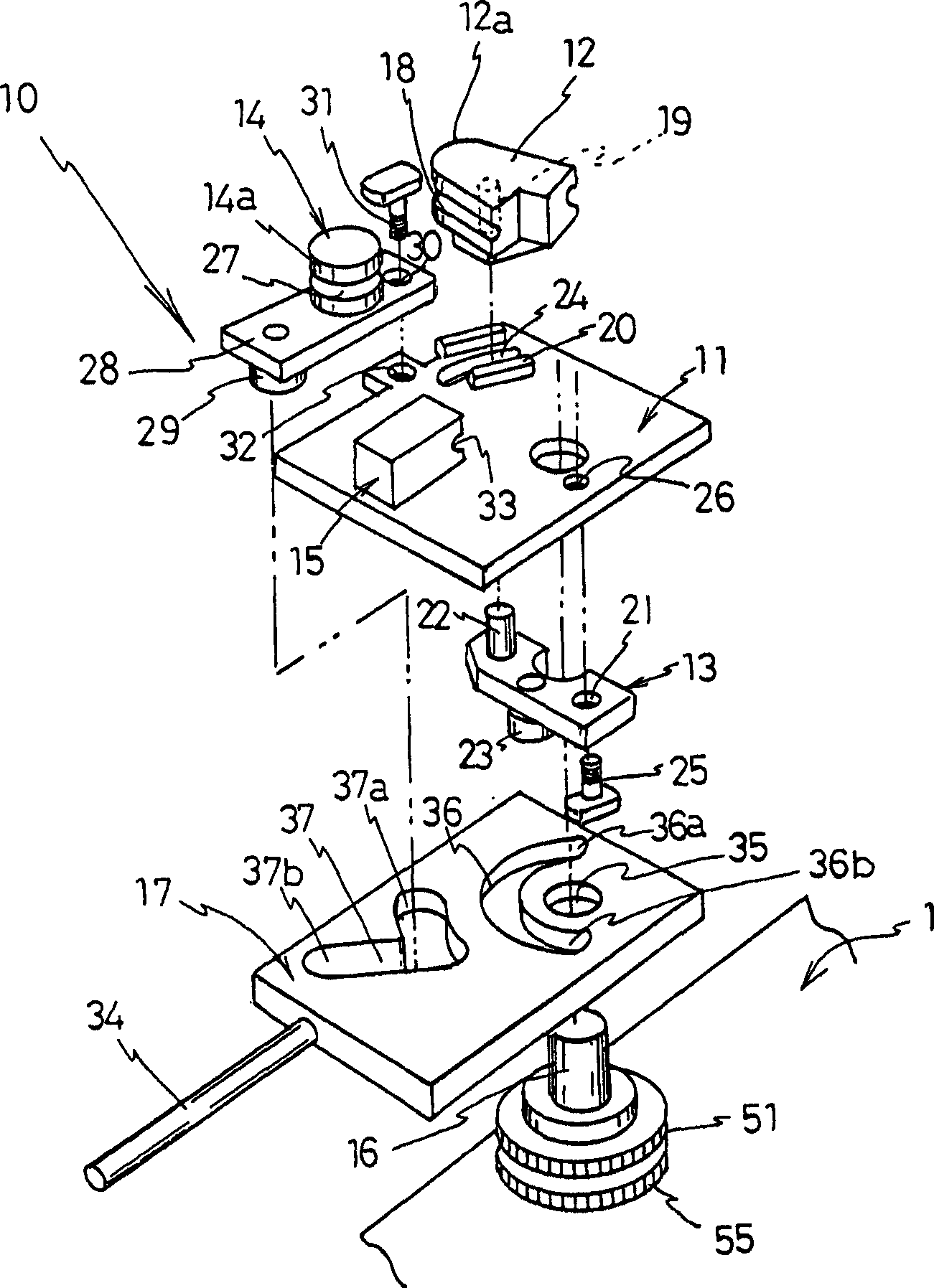

[0049] bend 10, such as figure 2 As shown in detail, the base plate 11 is provided with a gap above the frame 1 . The base plate 11 is provided with a bending die 12 , a bending die operating piece 13 , a pressure member 14 , and a jig 15 , and a shaft 16 is rotatably supported between the frame 1 and the base plate 11 . Furthermore, one end portion of the operation plate 17 is integrally provided on the shaft 16 .

[0050] The bending die 12 has a partially arc-shaped peripheral surface 12a, and an arc-shaped groove 18 for accommodating the pipe P is formed on the peripheral surfac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap