Dual-handle dual-function constant temperature valve core

A thermostatic valve core, dual-function technology, applied in the valve core field, can solve the problem that a single function must be combined with other valve cores, etc., to achieve the effect of safe and reliable operation and stable outlet water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

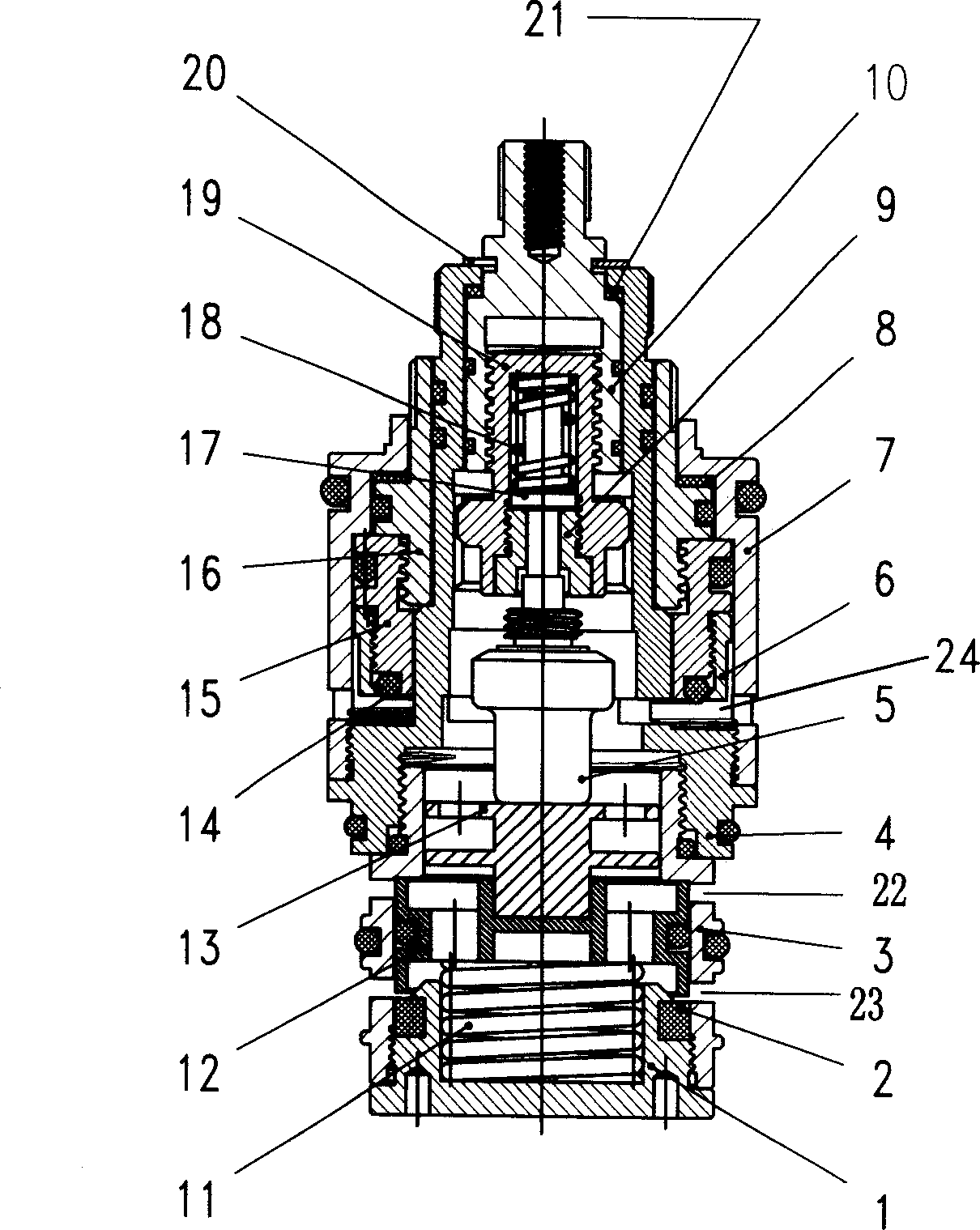

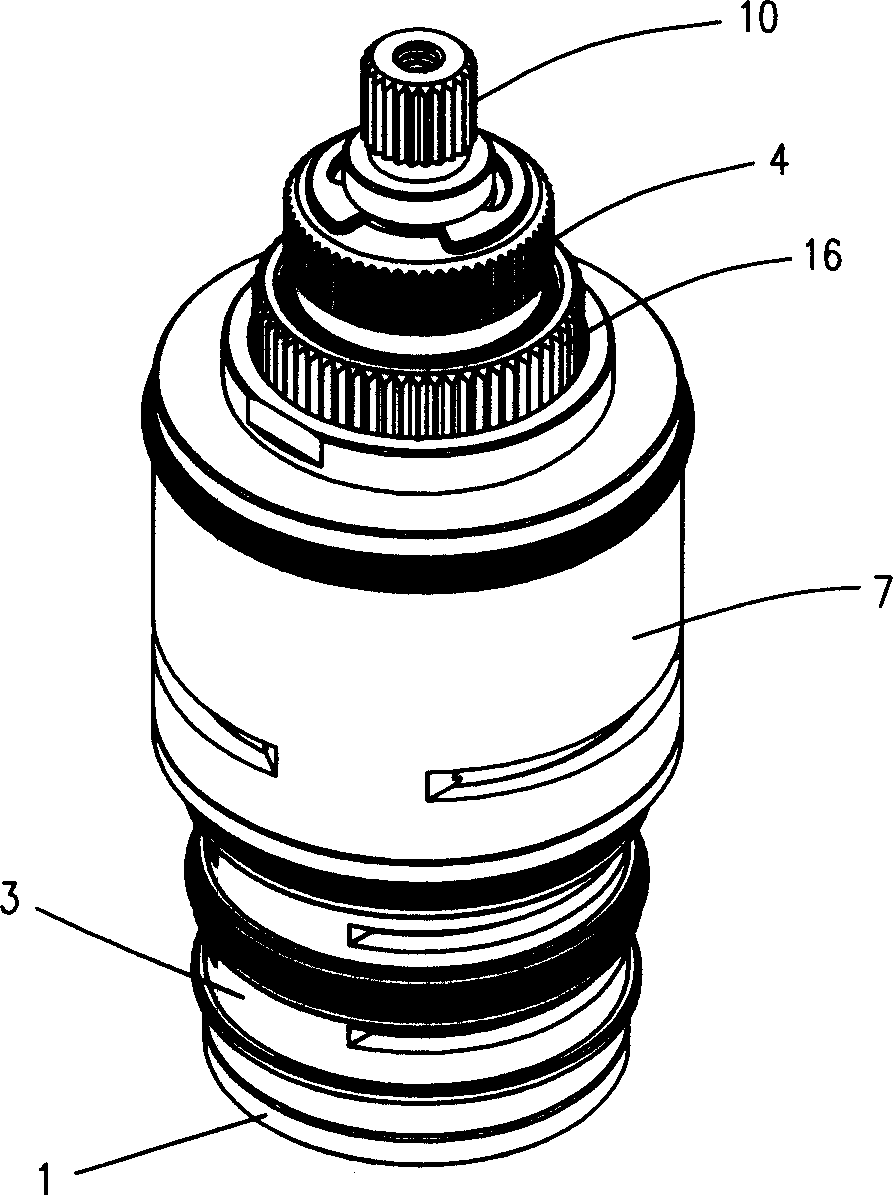

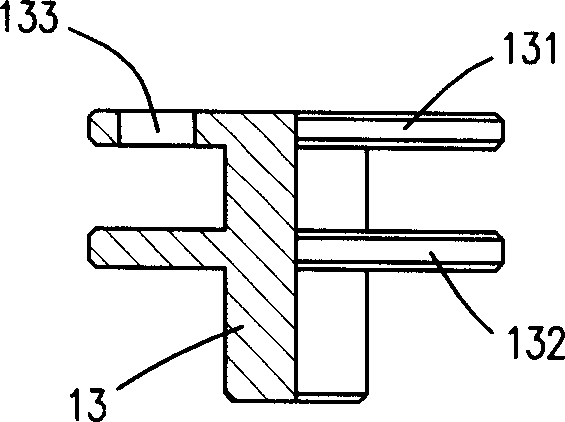

[0012] like figure 1 As shown, the double-handle dual-function valve core of the present invention includes a base 1, a sealing gasket 2, a thermostatic valve sleeve 3, a valve core body 4, a temperature sensor 5, a sealing ring compression nut 6, a jacket 7, a wear-resistant pad 8, and a push rod Seat body 9, thermostat valve stem 10, return spring 11, regulator 12, water mixer 13, sealing ring 14, flow regulating slide valve 15, flow regulating bolt 16, ejector rod 17, safety spring 18, collar 20 and O-rings of various specifications.

[0013] Combine below figure 1 and figure 2 Describe the details of each component and the connection relationship between components. The base 1, the thermostatic valve sleeve 3 and the valve core body 4 are sequentially connected to form a valve body together. Wherein, a gasket 2 is installed between the base 1 and the thermostatic valve sleeve 3 , the thermostatic valve sleeve 3 is provided with a cold water inlet 22 and a hot water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com