Solar energy heat utilization system combining thermal diode and phase change energy-storage material

A phase-change energy storage material and thermal diode technology, applied in the field of solar water heating system, can solve the problems of inability to exchange heat, decrease heat collection efficiency, easy freezing of pipes, etc. The effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

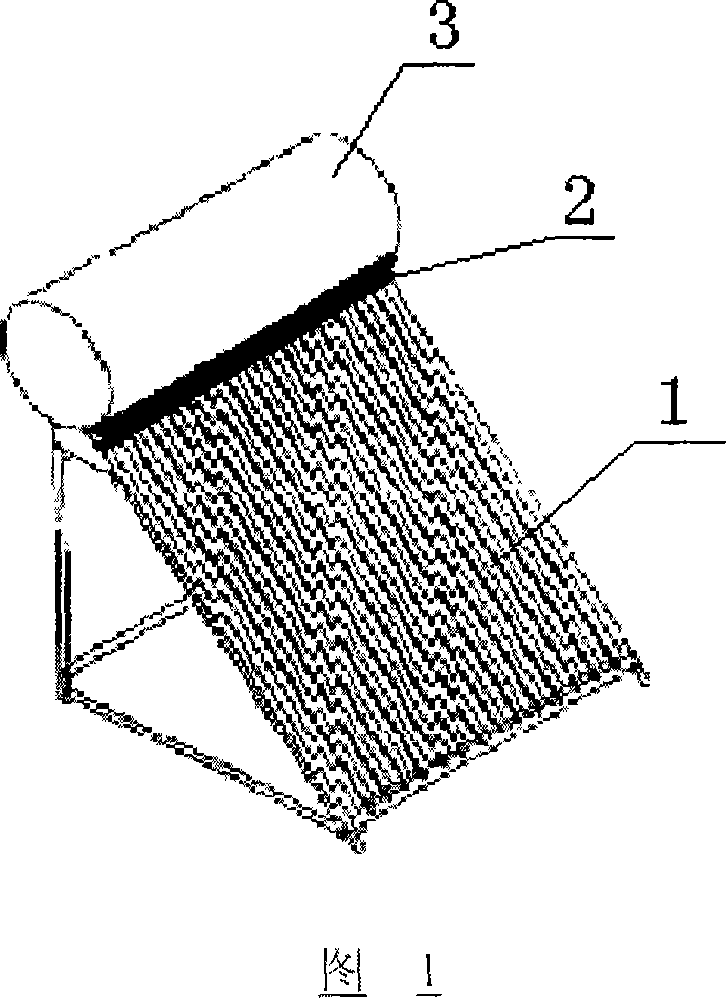

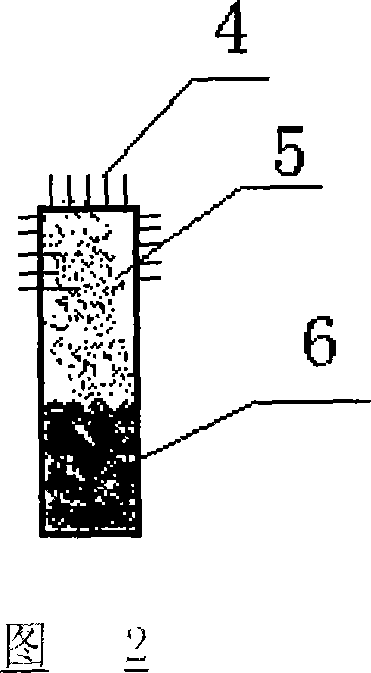

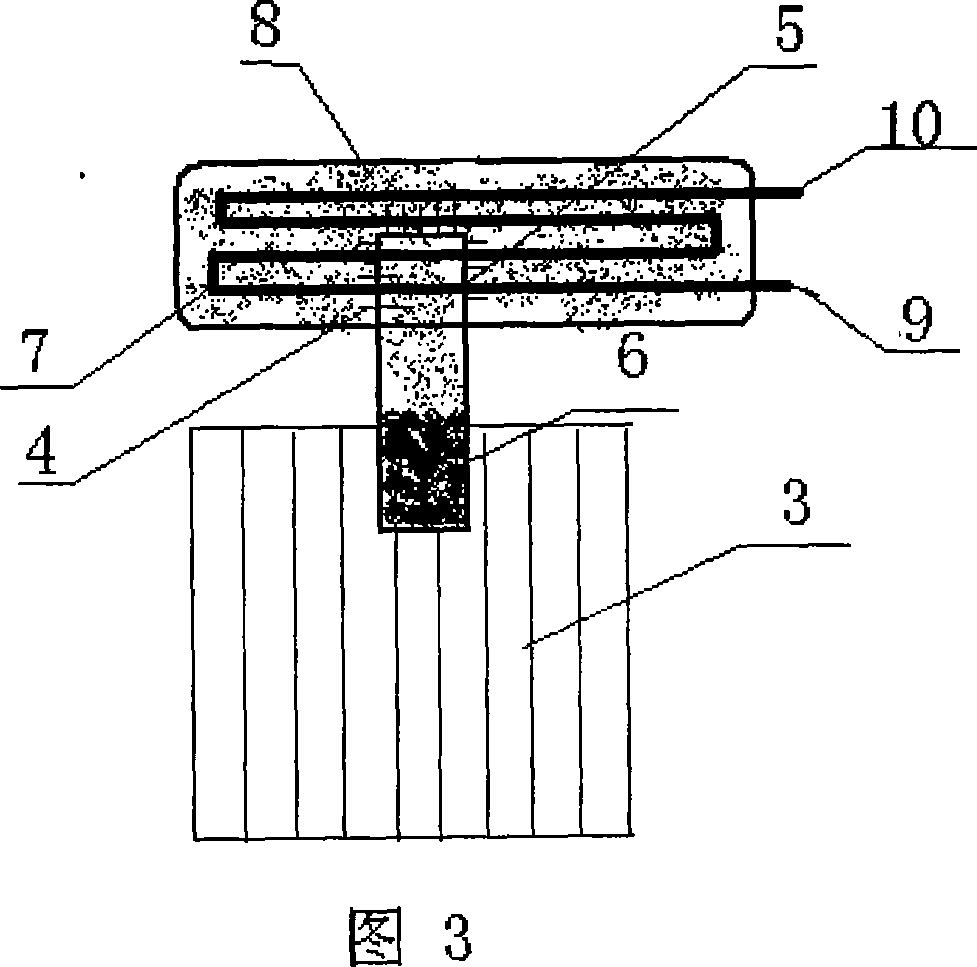

[0015] The structure of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Referring to Figures 1, 2, and 3, a solar heat utilization system is combined with solar thermal diodes and phase-change energy storage materials; thermal diodes use environmentally friendly refrigerant R134a as their internal working medium; when the intensity of solar radiation is high during the day, solar radiation energy Through the selective coating, the temperature of the heat collector is increased, and the heat is absorbed and conducted by the thermal diode in a conduction manner, so that the phase change material is heated and the phase change material absorbs heat and melts; because the temperature of the phase change material remains constant during the phase change Change, to ensure that the heat transfer temperature difference will not decrease with time, and improve the utilization rate of solar radiation energy. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com