Backlight module

A backlight module and light source technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of generating bright and dark bands, increasing costs, and insufficient lighting areas, reducing usage and avoiding the generation of bright and dark bands. , The effect of uniform and bright lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

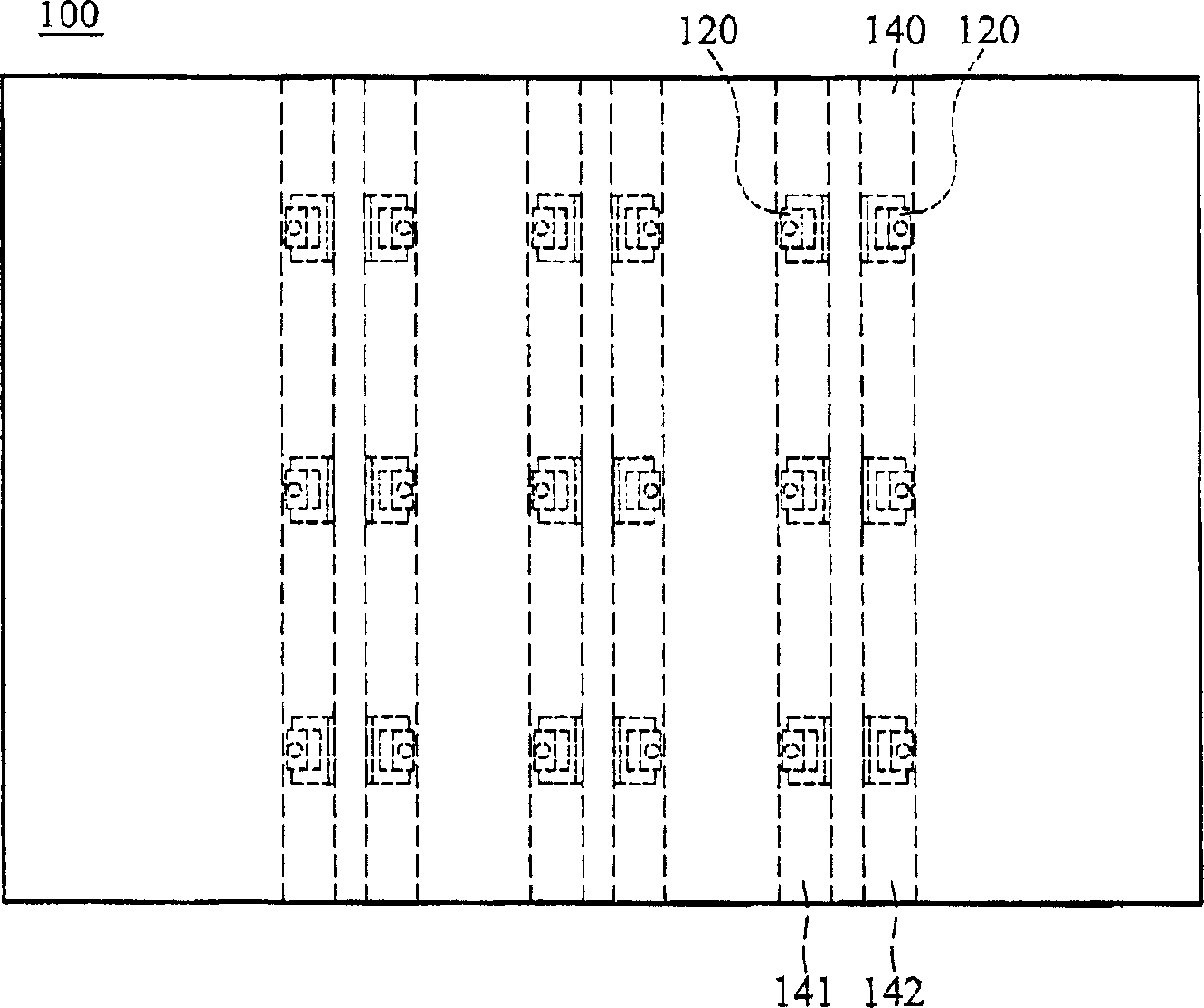

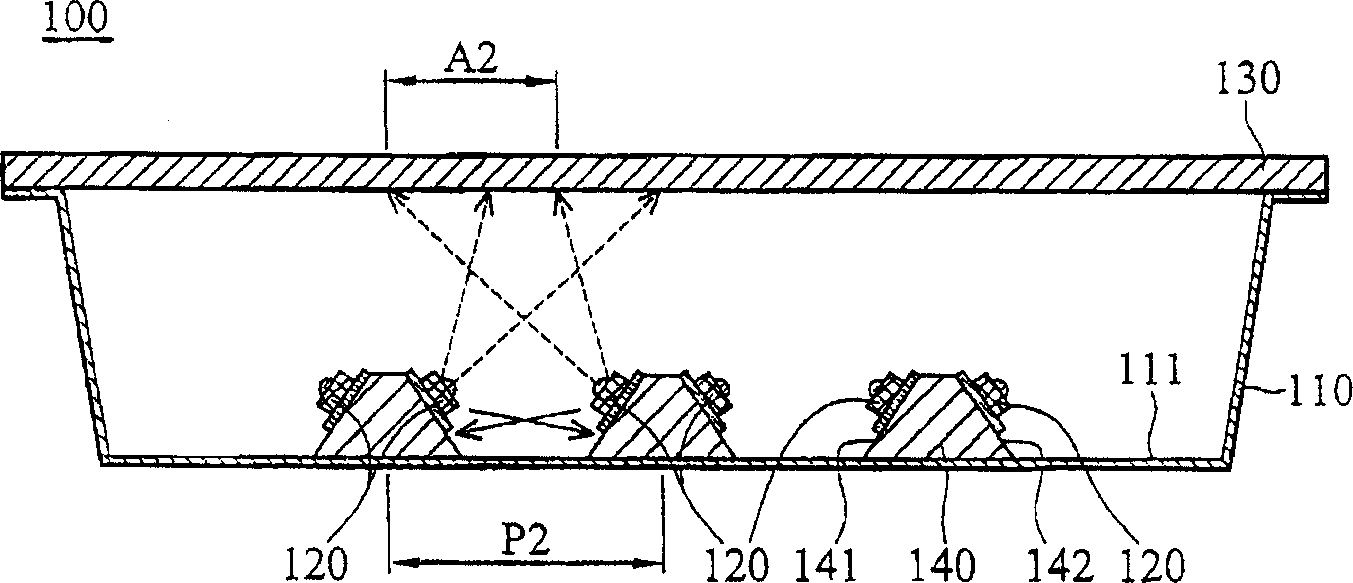

[0035] refer to Figure 2a as well as Figure 2b , which shows the backlight module 100 according to the first embodiment of the present invention, including a reflector 110 , a plurality of light sources 120 , a plate 130 and a plurality of heat conducting structures 140 . The reflective plate 110 has a reflective surface 111 . The heat conducting structure 140 is disposed on the reflective surface 111 and includes a first side 141 and a second side 142 . The light source 120 is disposed on the first side 141 and the second side 142 .

[0036] The material of the heat conducting structure 140 can be metal or ceramics. The light source 120 is a light emitting diode (LED). The board 130 can be a diffuser board or a brightening sheet.

[0037] In the embodiment of the present invention, since the illumination of each illumination area (for example, illumination area A2) is provided by multiple light sources 120 at the same time, therefore, there will not be the problem that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com