Elastic full effect traction coupling device

A technology of spring string and traction ring, which is used in traction connectors, transportation and packaging, vehicle components, etc., can solve the problems of trailer load not exceeding the limit, rigid destructive impact, etc., to improve service life, save fuel, improve The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

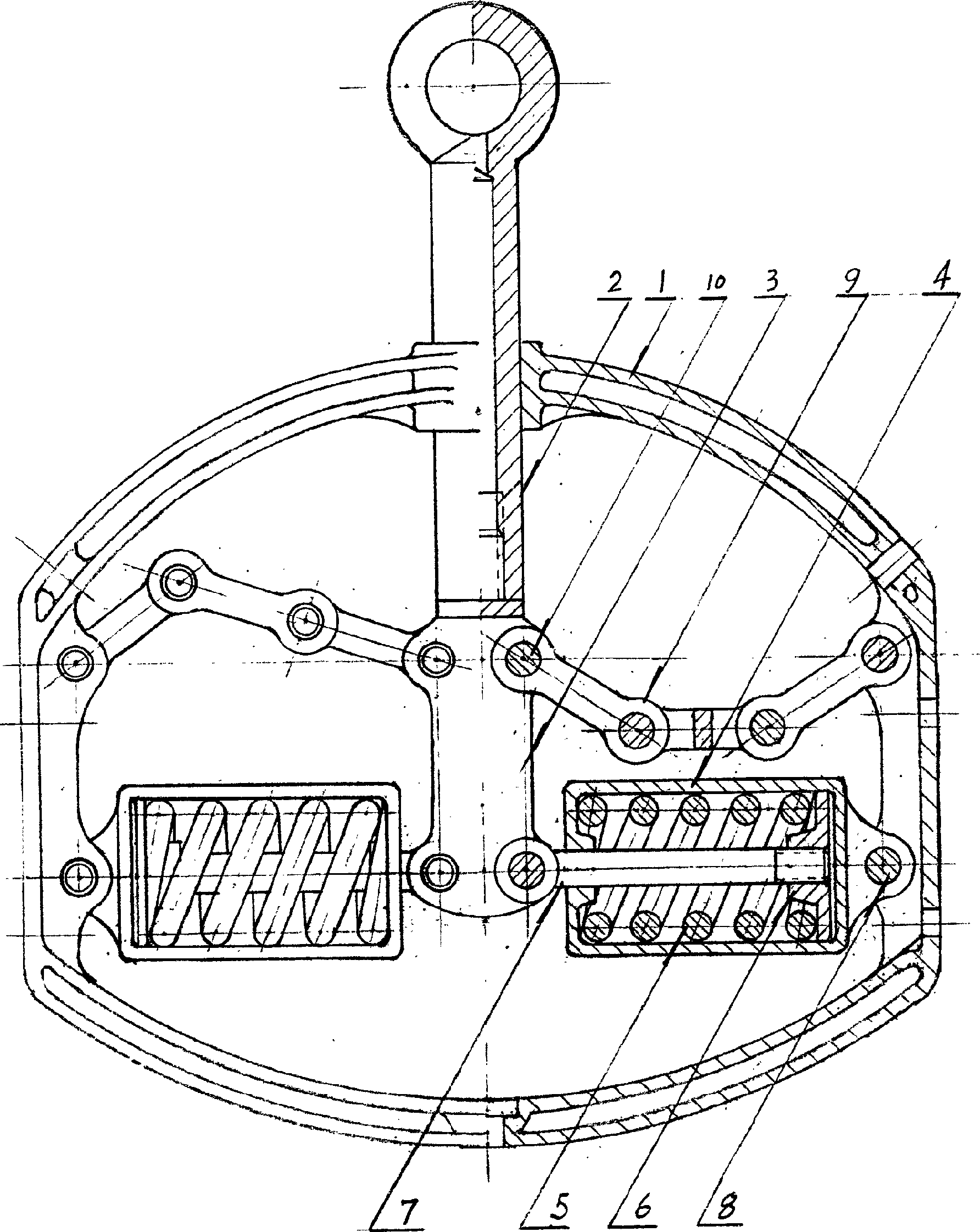

[0012] In the accompanying drawings, the bow frame 1 is like two types of bows with the bow ends symmetrically abutting against the notch towards the two grooves in the frame. In the center of the back of the bow body of its class, there is a shaft hole for wearing the traction ring rod 2 and moving with it. On the inside of the groove body at the two bow ends of the bow without shaft holes, there is a groove cavity for the end pin lugs of the inserting frame cover 4 that can be symmetrical, and a pin hole that is statically matched with the string pin 8 is arranged on the groove body. There is a groove cavity for symmetrically inserting and installing the chain end plate of the control chain 9 inside the groove body at the two bow ends of the bow with the shaft hole, and there are pin holes statically matched with the chain pin 10 on the groove body; the traction ring rod 2. There is a traction ring at one end of the rod shaft, and the other end has a screw hole for the stud ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com