Print quality detecting and controlling system based on image intelligent identification

A technology of intelligent recognition and control system, applied in character and pattern recognition, measurement device, material analysis by optical means, etc., to meet the high-speed online measurement and control environment and reduce unit cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

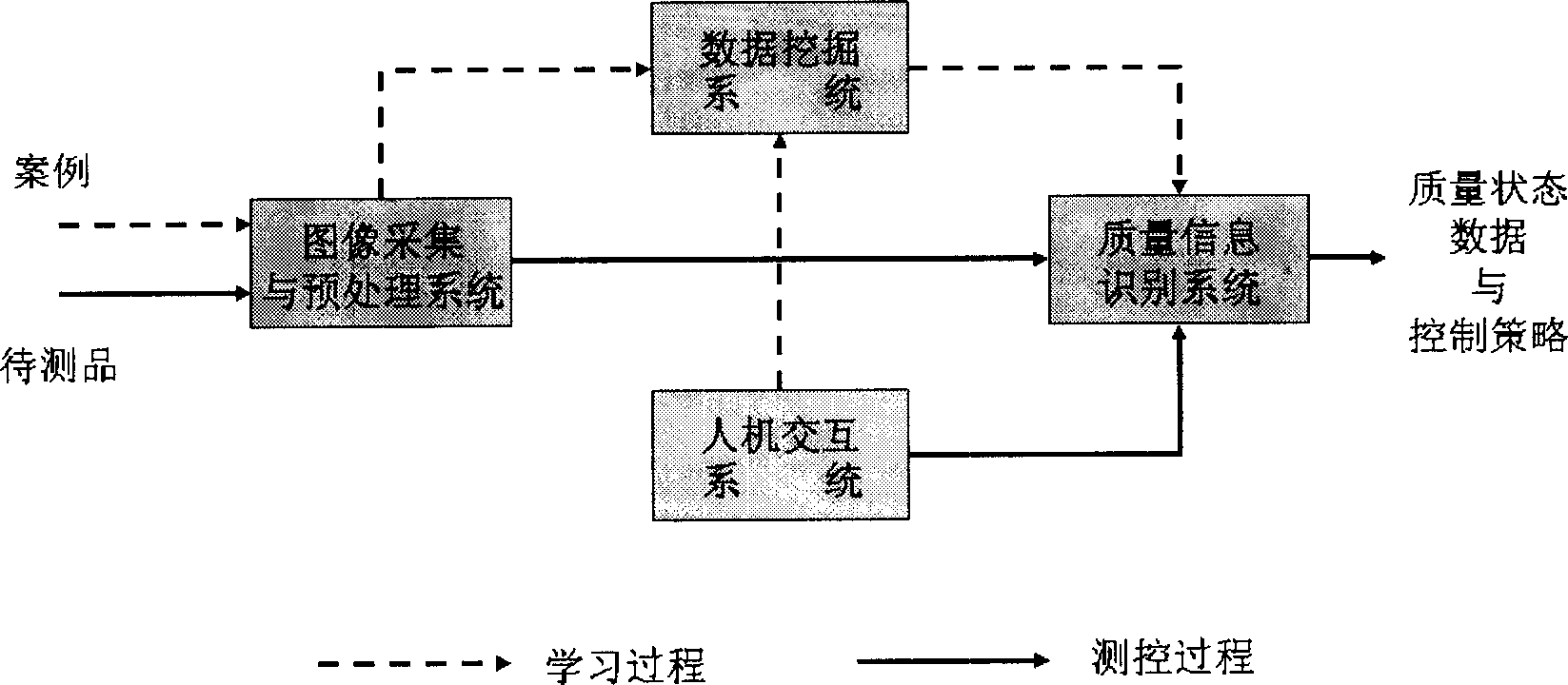

[0013] The invention provides a printed product quality detection and control system based on image intelligent recognition, which obtains quality variation information by collecting, analyzing and identifying images of the microscopic structure that constitutes the color and level of the printed product, and according to the type and level of the variation information The corresponding control strategy is automatically given according to the degree of size.

[0014] see figure 1 , which is a structural schematic diagram of a printed matter quality detection and control system based on image intelligent recognition in the present invention. As shown in the figure: the system consists of four parts: image acquisition and preprocessing system, data mining system, quality information identification system, and human-computer interaction system. It consists of image acquisition and preprocessing system, data mining system, quality information identification system, human The comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com