Simulator measurement and control system based on multi-point measurement compensation method

A measurement and control system and multi-point measurement technology, which is applied in the field of simulator measurement and control, can solve the problems of rapid increase in failure rate and reduced reliability, and achieve the effects of reduced maintenance costs, high reliability, and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

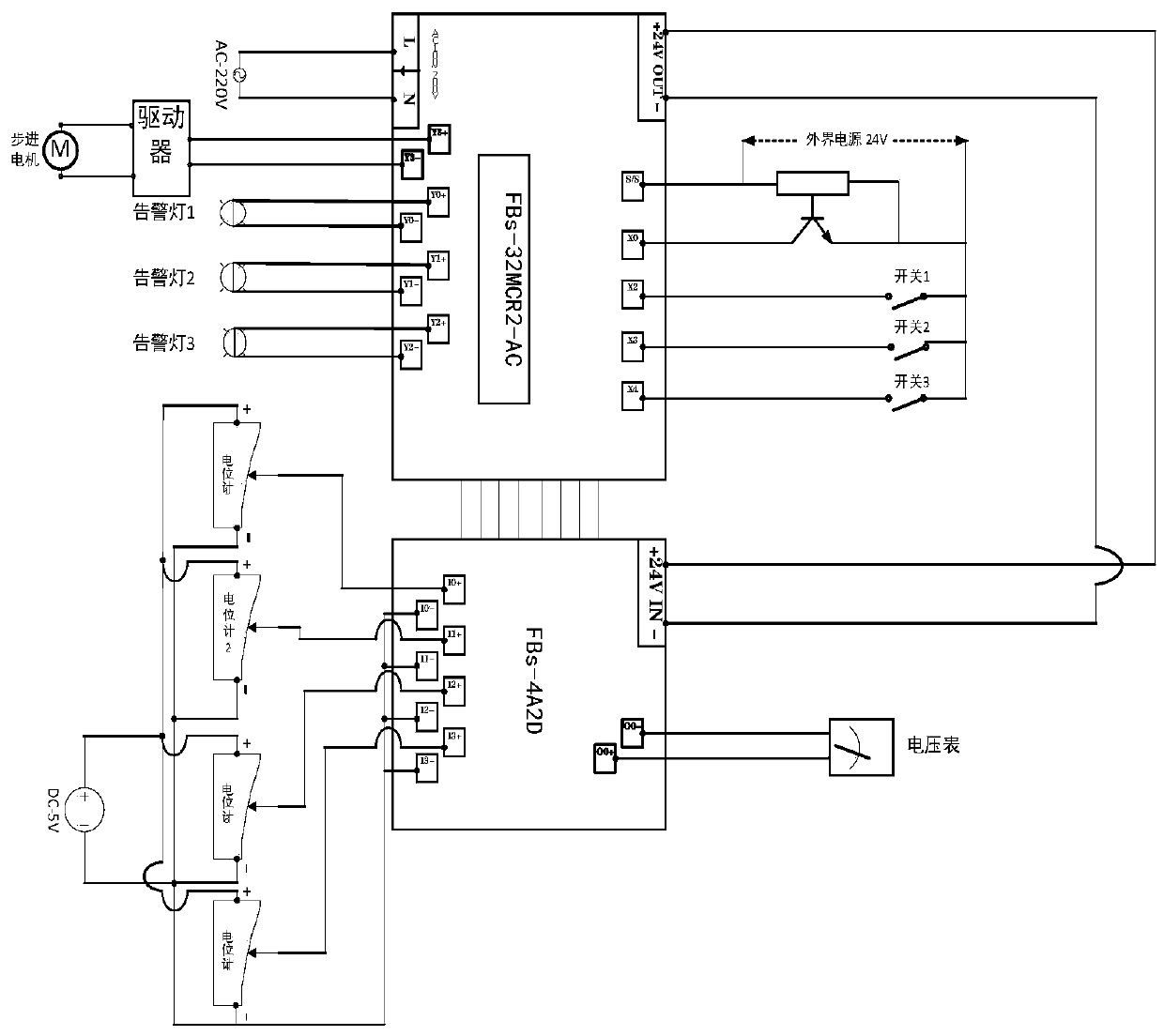

[0088] Attached below Figure 1-26 , a simulator measurement and control system based on the multi-point measurement compensation method of the present invention will be described in detail below.

[0089] 1. Measurement and control system scheme design

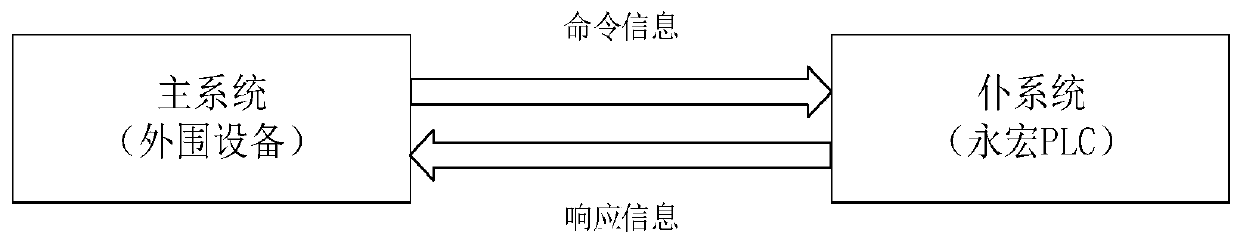

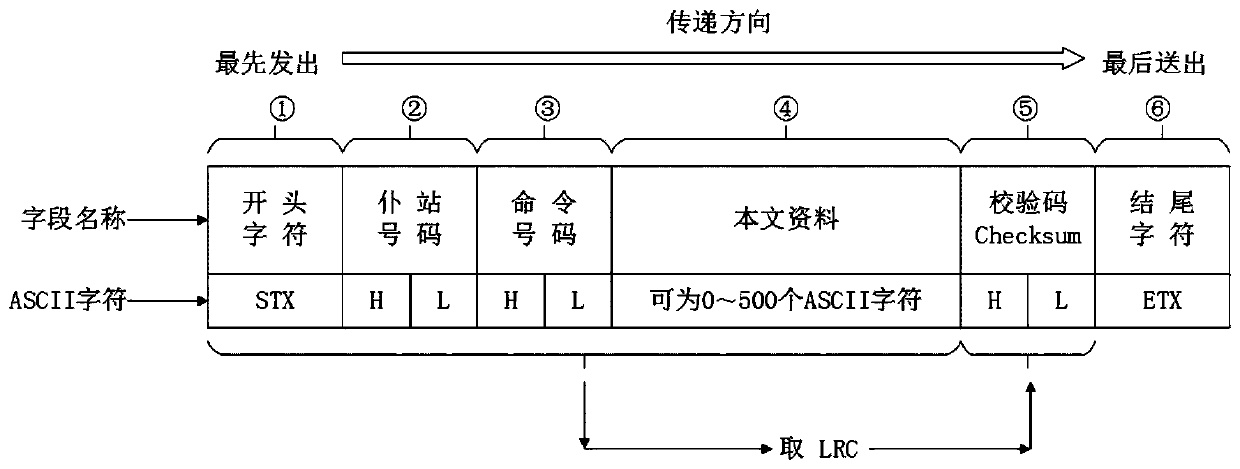

[0090] The measurement and control system designed by the present invention is mainly composed of a main control computer, a measurement and control computer (upper computer), a PLC host (lower computer), various switches, buttons, warning lights, indicator lights, throttle levers, knobs, and push rods from top to bottom. , instrument pointer, stepping motor, etc., the task is to measure and control the switching value, analog value, pulse value, etc.

[0091] The main task of the main control computer is to visually display the data uploaded by the measurement and control computer, and at the same time coordinate the normal operation of each measurement and control computer.

[0092] The main task of the measurement and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com