Method for preparing polyimide and polyimide prepared thereby

一种聚酰亚胺、低聚物的技术,应用在制备聚酰亚胺和由此制备的聚酰亚胺领域,能够解决难以加工、混合物粘稠、没有广泛地实践熔融聚合等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0092] This example describes the preparation of a mixture of oligomers. The reaction mixture consisted of 14000 g bisphenol A dianhydride (BPADA), 2490.98 g m-phenylenediamine (mPD), 177.1 g phthalic anhydride (PA) and 30109 g o-dichlorobenzene (o-DCB). The o-DCB, BPADA, and PA were charged into a 50-gallon glass reactor, and the mixture was stirred at room temperature overnight. The mixture was then heated to 160°C under nitrogen, and molten mPD was added to the reaction mixture in increments within about 24 minutes. When water started to form in the reactor, the temperature of the reaction mixture decreased from about 157.1°C at the beginning of the mPD addition to about 146.8°C at the end. Samples of the solution mixture taken from the reactor at different times showed that the molecular weight of the oligomer (M w / M n / PDI) was 18966 / 8767 / 2.163, and 25013 / 11197 / 2.234 after about 45 minutes from the time when all mPD was added to the reactor. This solution containing oligomer...

Embodiment 1-5

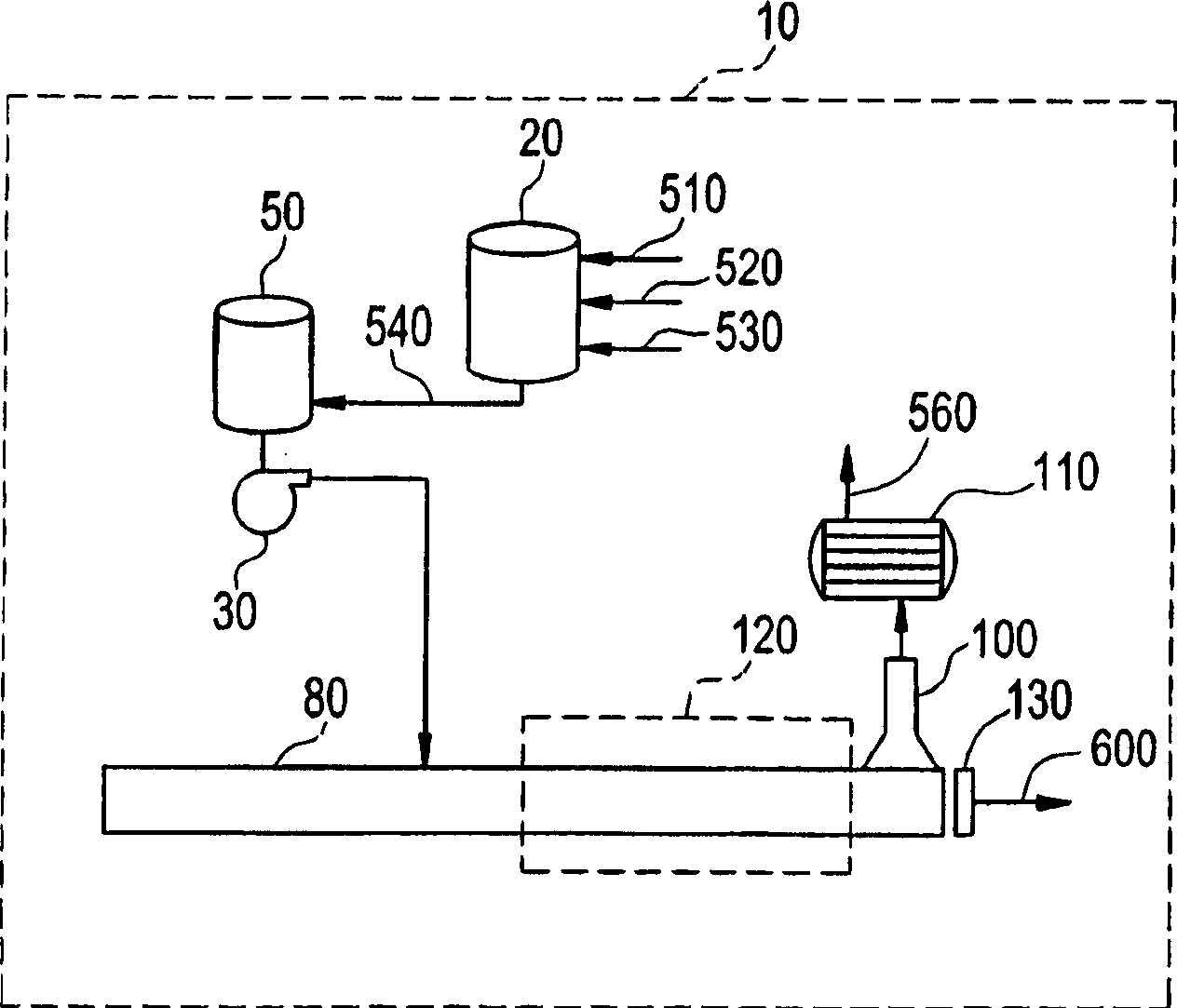

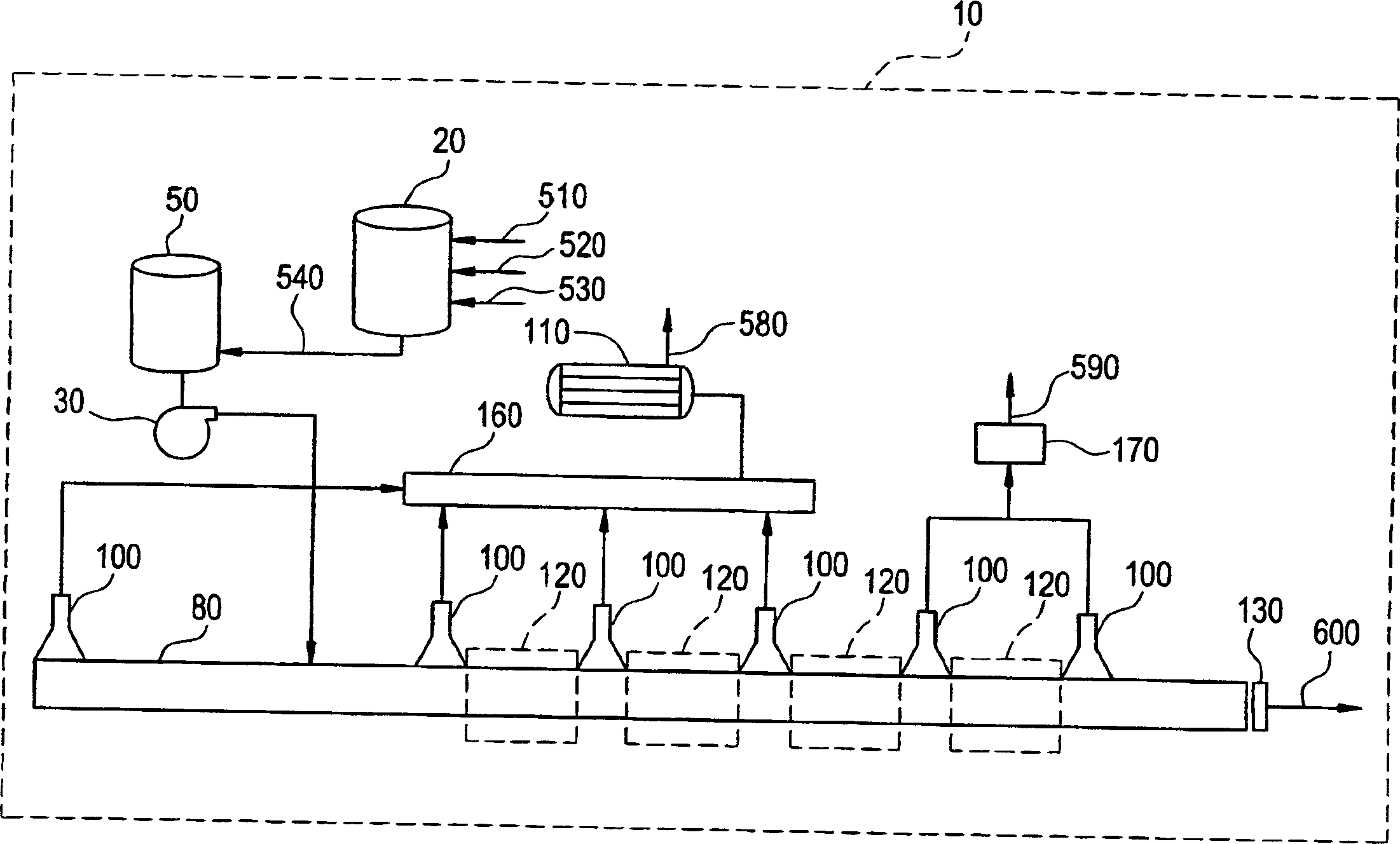

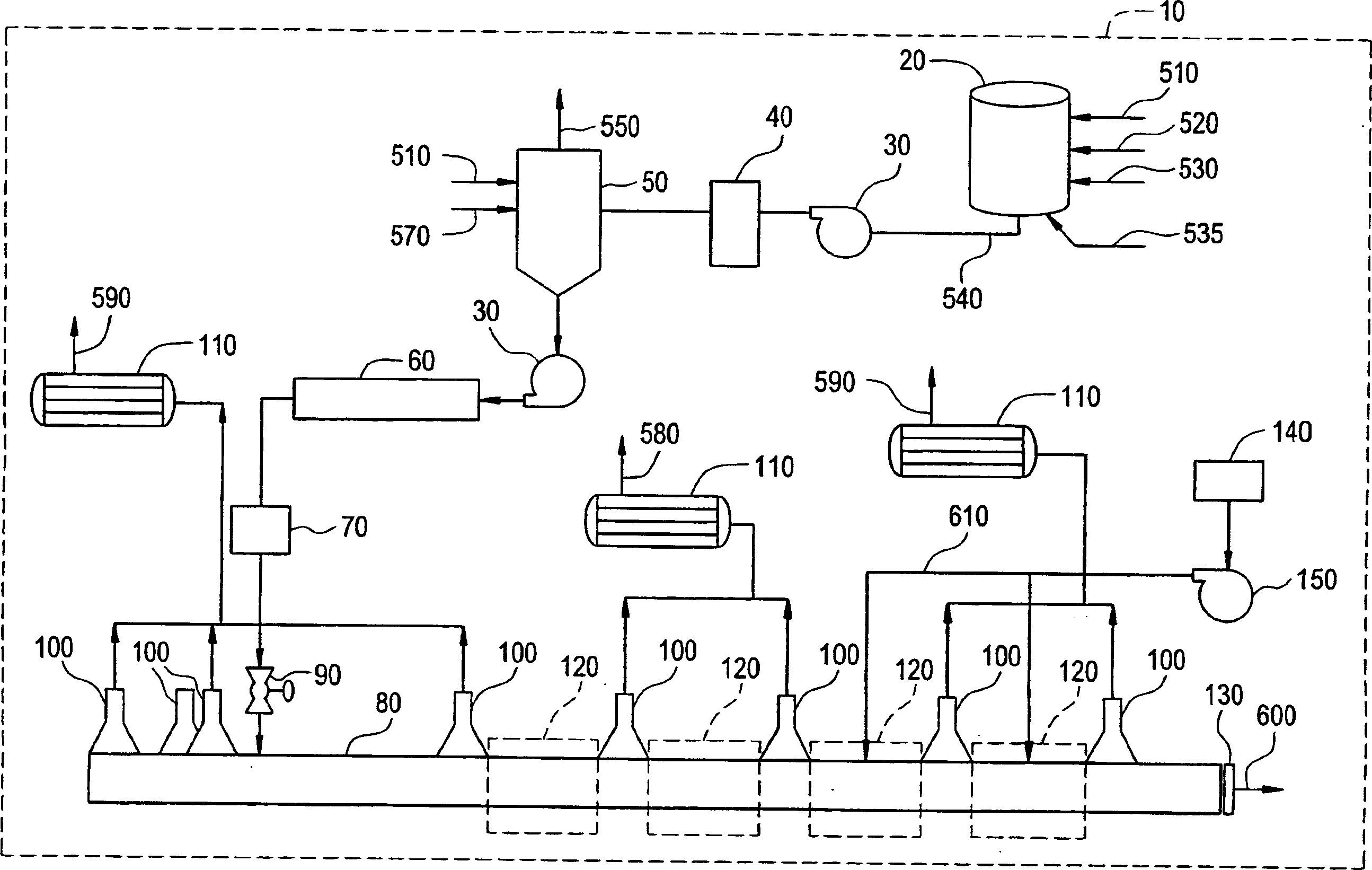

[0094] The oligomer solution obtained from Preparation Example 1 and containing about 35 wt% of oligomer in o-DCB was continuously fed into the extruder from a heating tank maintained at about 165-170°C. Extruder structure and above figure 2 The similarity. The extruder is a 25mm diameter, co-rotating, intermeshing twin-screw extruder, and it includes 14 cylinders (total extruder length to diameter ratio L / D is 56) and 6 for removing Orifice for volatile components. Add the oligomer solution to the extruder at cylinder number 4. The solvent o-DCB is removed from the process through the vacuum orifices located at cylinder number 1 (orifice at the rear) and 5, 7, 9, 11 and 13 (orifices at the front). All extruder orifices work under a relatively high degree of vacuum corresponding to a pressure of about 25 mm Hg. The orifice 2 at the cylinder 5 does not have a vacuum gauge. The screw of the extruder is designed to provide a relatively long reaction residence time and frequent surfa...

preparation Embodiment 2

[0101] The reaction mixture consisted of 14050 g BPADA, 2941 g mPD, 177.1 g PA, and 30.1 kg-DCB. The amount of BPADA is 50 g more than that in Preparation Example 1, to balance the amine-rich product in that Example. The o-DCB, BPADA, and PA were charged into a 50-gallon glass reactor, and the mixture was stirred at room temperature overnight. The mixture was then heated to 160°C under nitrogen, and molten mPD was added to the reaction mixture in increments in about 36 minutes. When water started to form in the reactor, the temperature of the reaction mixture dropped from about 155.2°C at the beginning of the mPD addition to about 152.5°C at the end. Samples of the solution mixture taken from the reactor at different times showed that the molecular weight of the oligomer (M w / M n / PDI) was 25873 / 11060 / 2.339, and 28544 / 12225 / 2.335 after about 45 minutes, both of which were taken from the time when all mPD was added to the reactor. This solution containing an oligomer with a weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight-average Molecular Weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com