Spraying plant for cylinder inside surface coating

A spraying device and coating technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of slowing down the moving speed of the nozzle, the inability to complete small sizes, and longer working hours, so as to improve the coating efficiency , moving speed guarantee, efficient inner surface coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

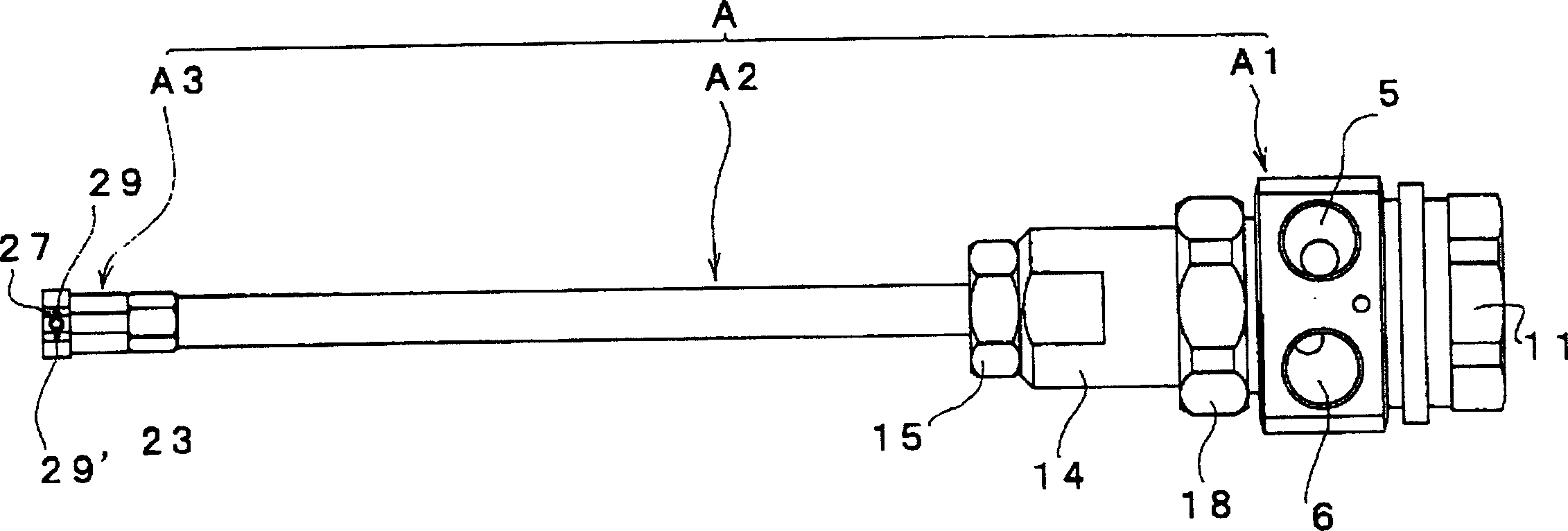

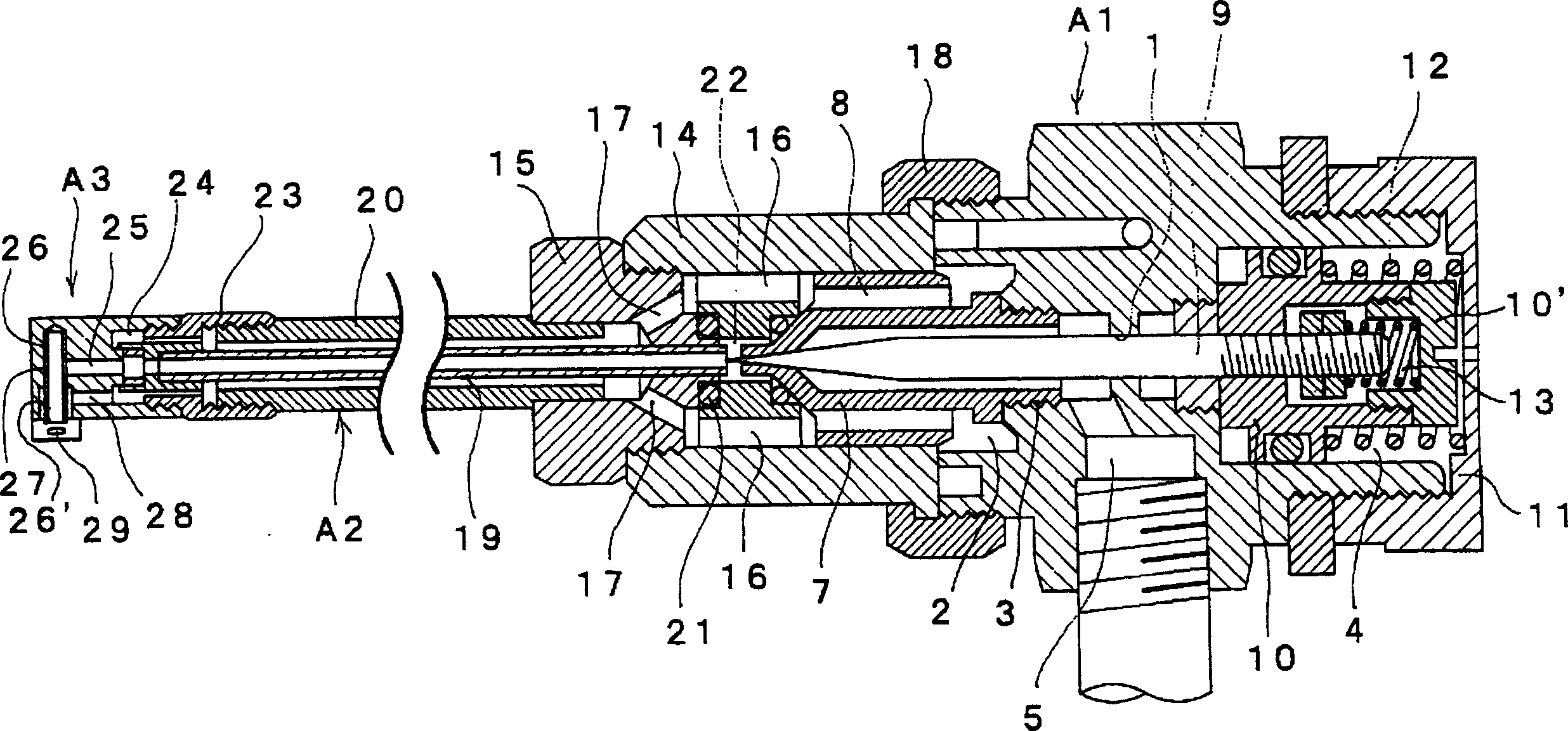

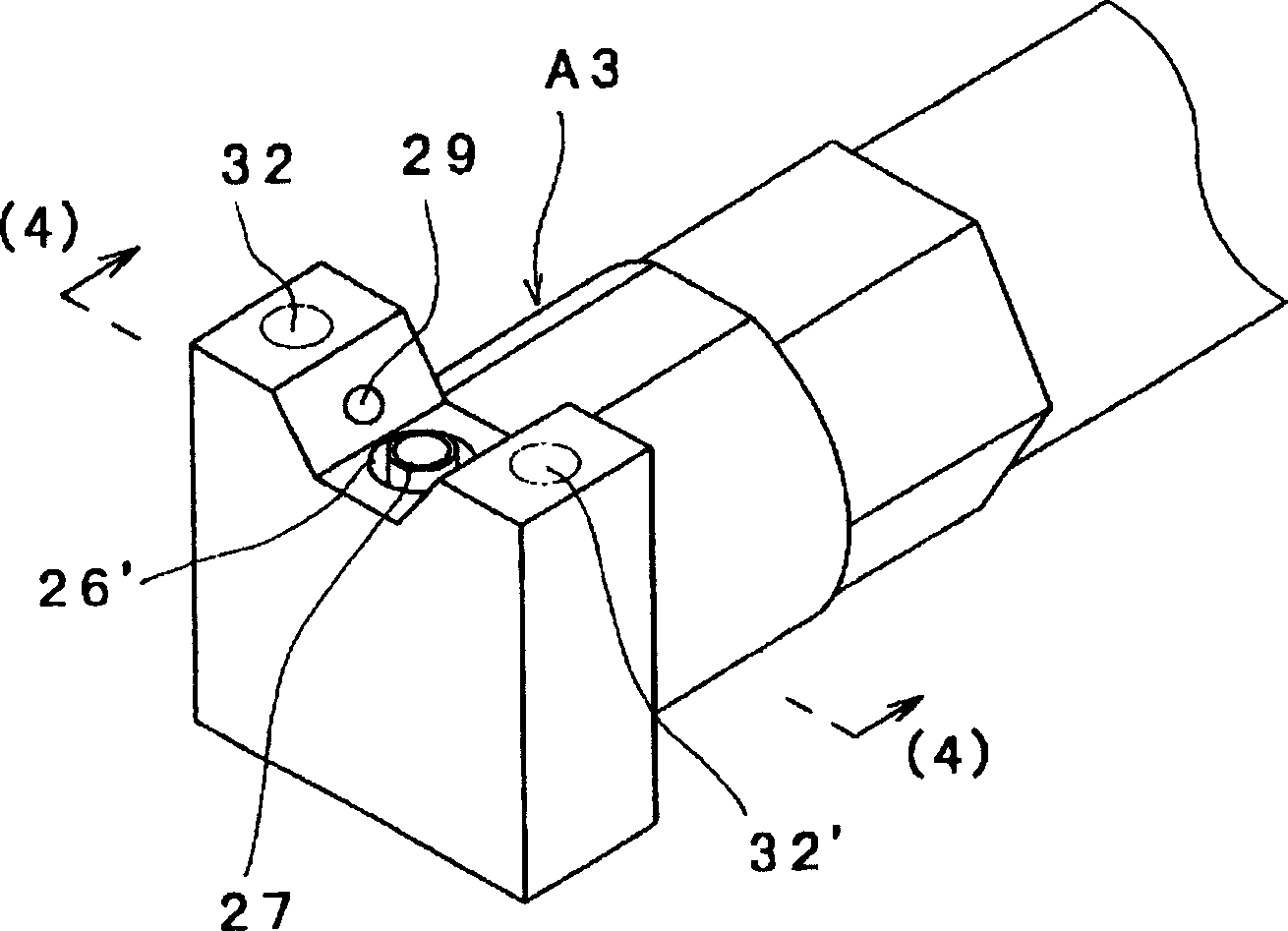

[0032] Hereinafter, an embodiment of the spraying device for coating the inner surface of a cylinder according to the present invention will be described with reference to the drawings.

[0033] figure 1 It shows the appearance of the spraying device A. In the figure, A1 is a body equipped with a liquid supply port, an air supply port, and a liquid volume adjustment device, etc., and a pipe body A2 is connected to the top of the body A1, and the pipe body A2 connects the liquid passage and The air passage is formed concentrically, wherein the liquid passage is formed in the center and the air passage is formed around it, and the spray head A3 is detachably connected to the top of the pipe body A2, and the spray head A3 is along the axis of the pipe body A2 The direction perpendicular to the center forms the spray port for vertical and flat spraying.

[0034] The main body A1 is a common product commonly used by this spraying device, such as figure 2 As shown, a needle valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com