Filter-efficiency inspection system for efficient and super-efficient air filter

An air filter and filtration efficiency technology, applied in the direction of dispersed particle filtration, instruments, measuring devices, etc., can solve the problems of not meeting the detection of high-efficiency air filters, not adapting to the detection of industrialized production batch products, etc., to improve the technical level and improve the Ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

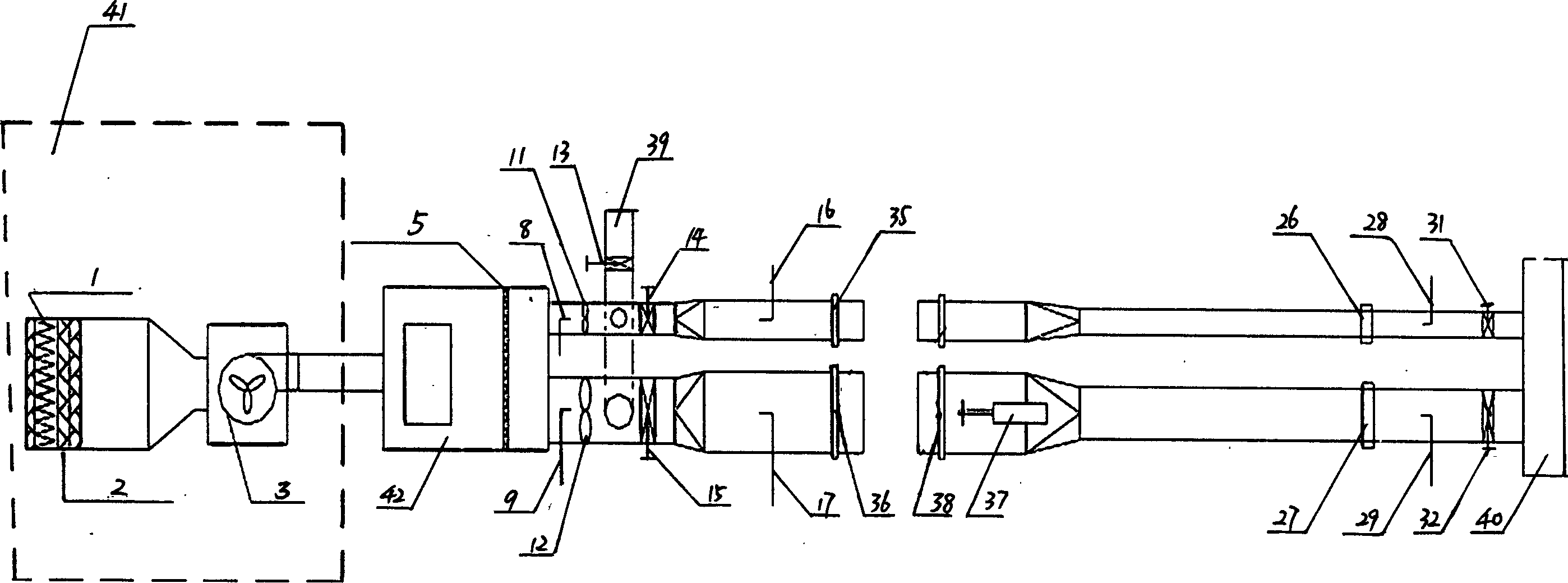

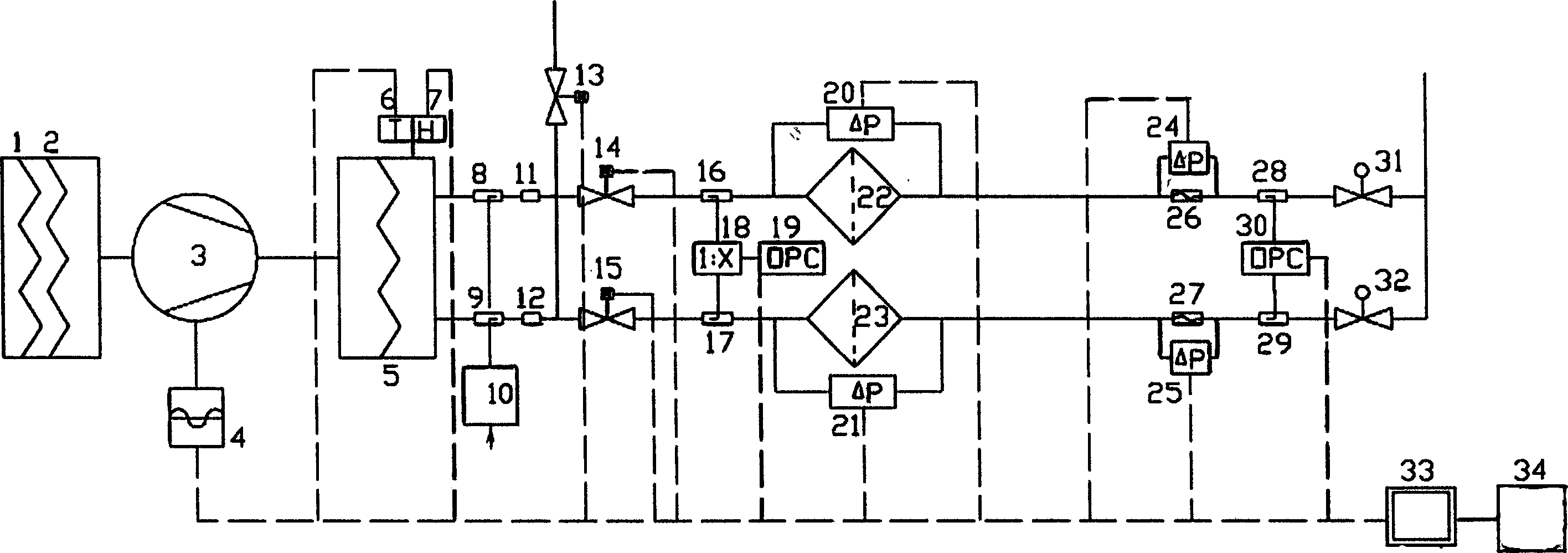

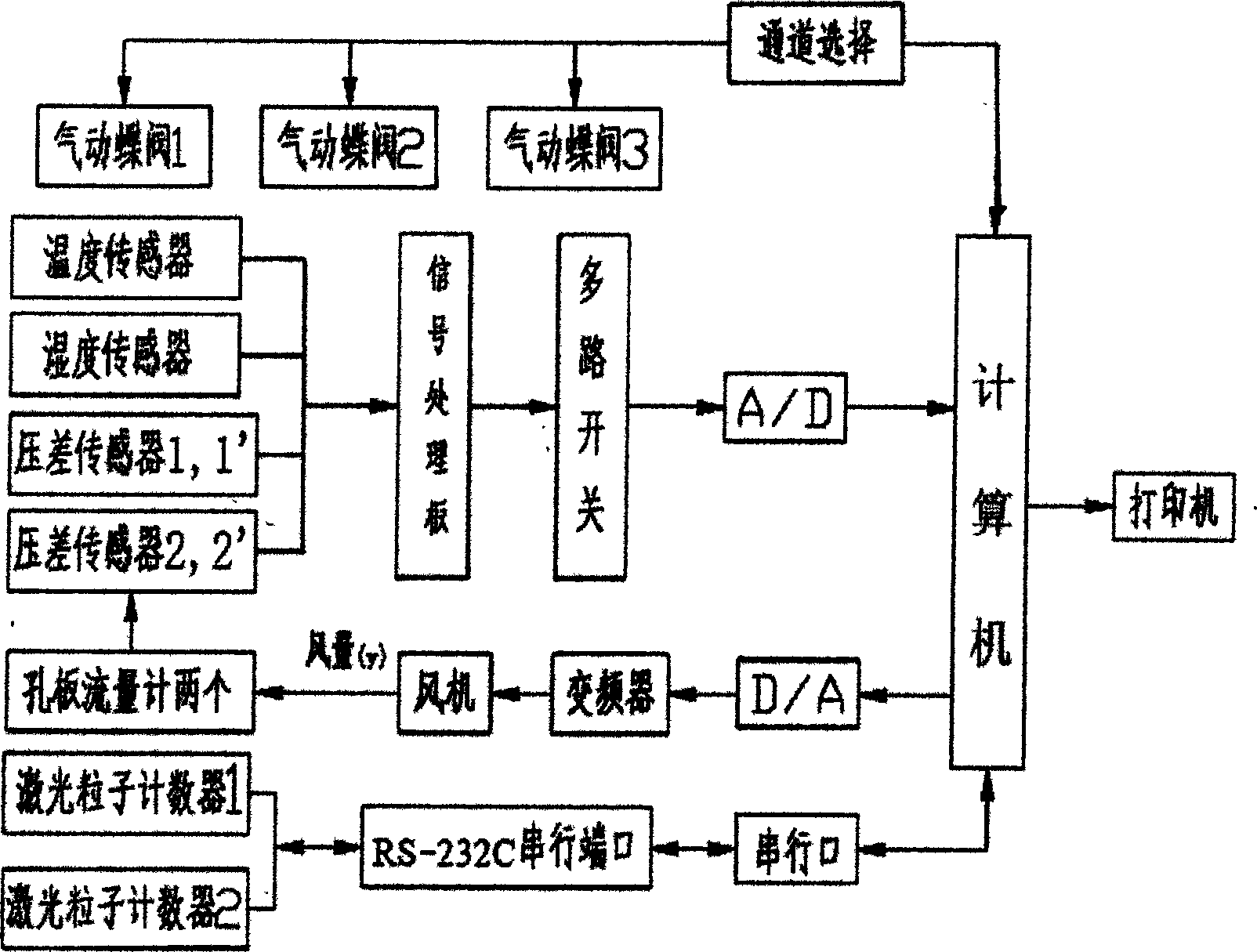

[0019] like figure 1 As shown, the fan room 41 is provided with an air inlet pipeline, and the air inlet pipeline is provided with an initial effect filter 1, a medium-efficiency filter 2, and a fan 3 in sequence, and the air inlet pipeline is connected to the air supply room 42 where a high efficiency filter 5 is installed, and the air inlet pipeline The air room is respectively connected to the first and second upstream test passages, and the dust generation pipes 8 and 9, flow mixing devices 11 and 12, airtight valves 14 and 15, upstream sampling pipes 16 and 17, Static pressure rings 35 and 36, first and second downstream test passages are arranged adjacent to the first and second upstream test passages, and the first and second downstream test passages are respectively composed of sliding passages and orifice plate flowmeters arranged in sequence in the passages ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com