Ink-ribbon transfer device capable of fixing rotary roller

A transmission device, a technology of fixing the rotating shaft, applied in the direction of inking device, ink ribbon cassette, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

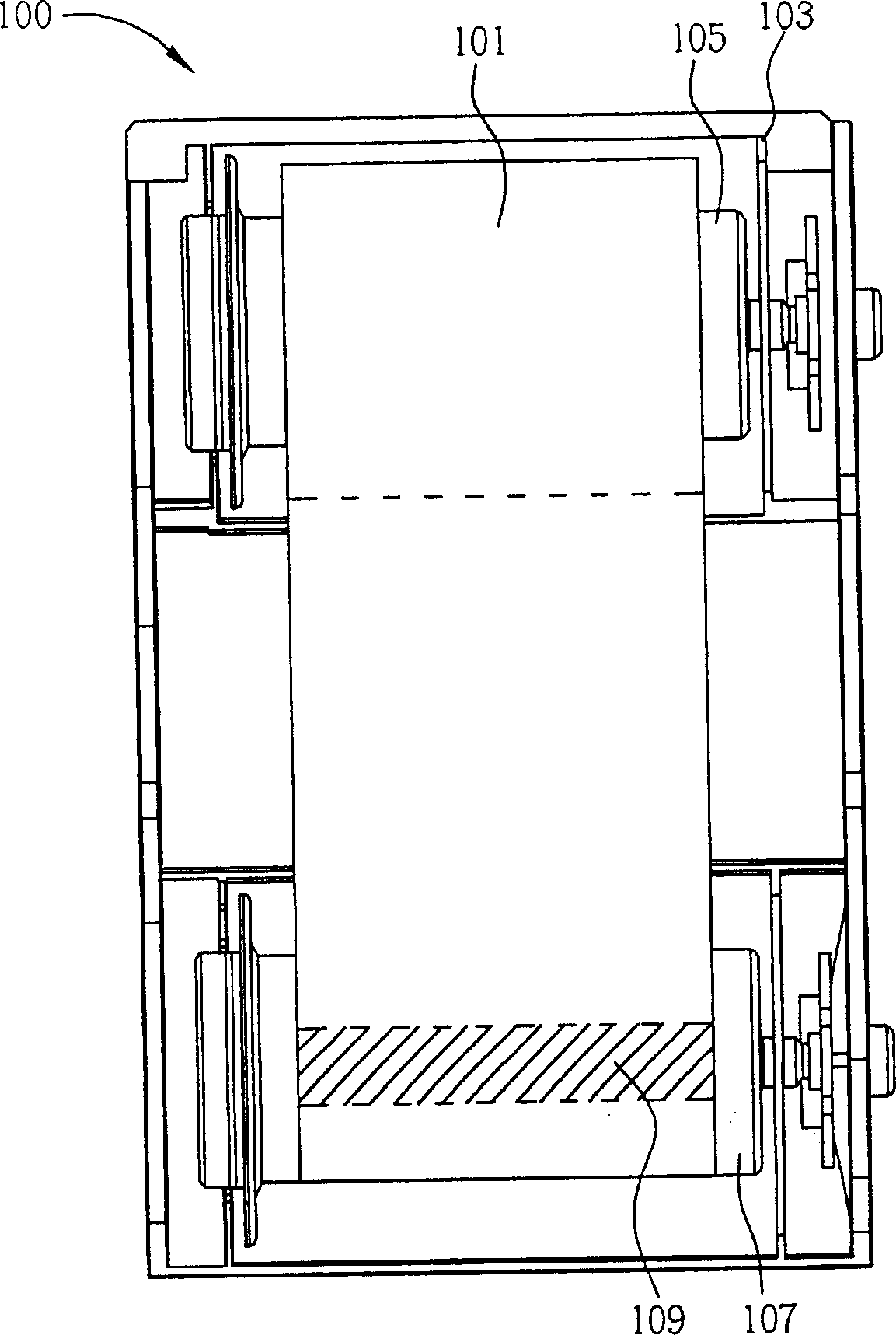

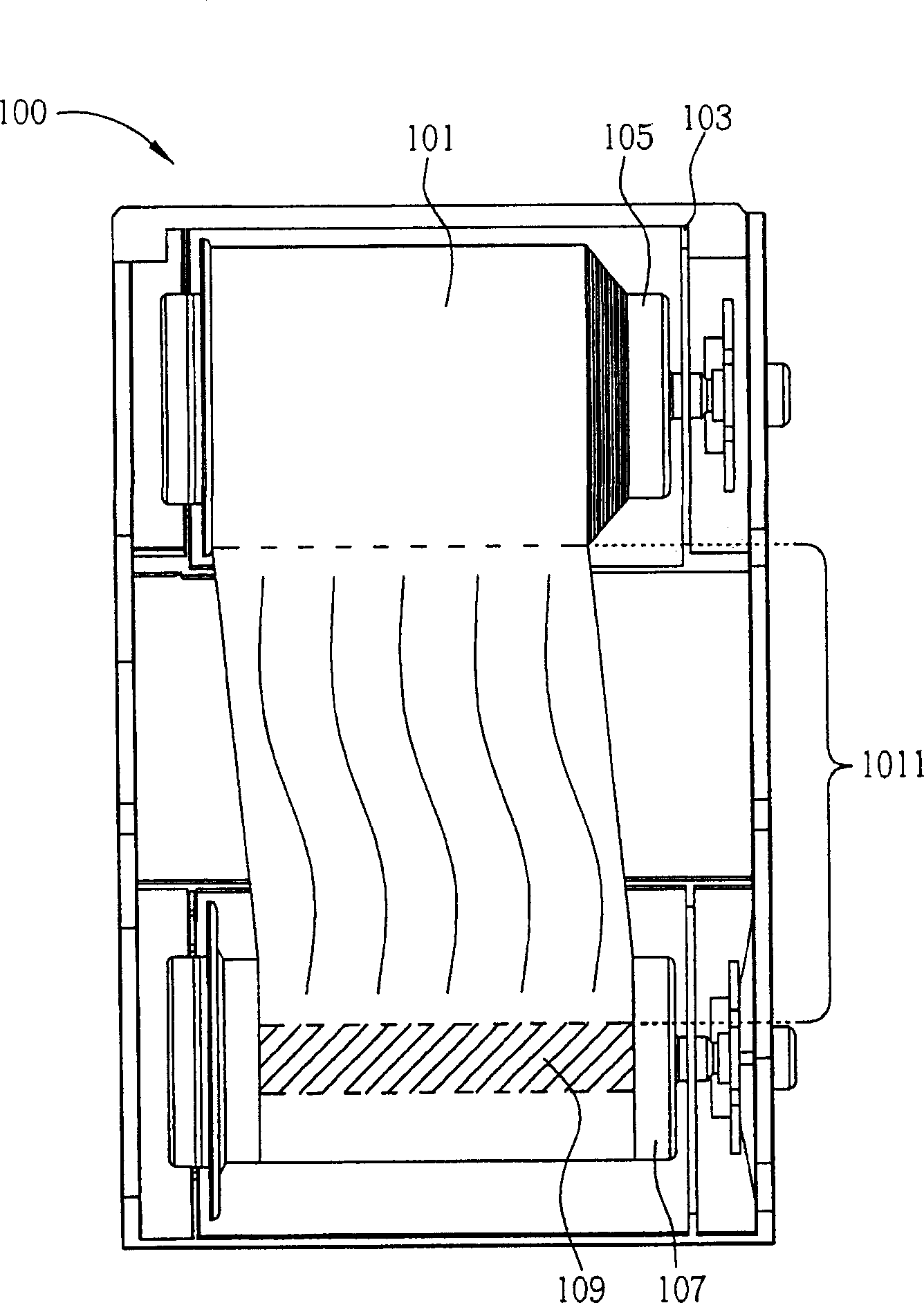

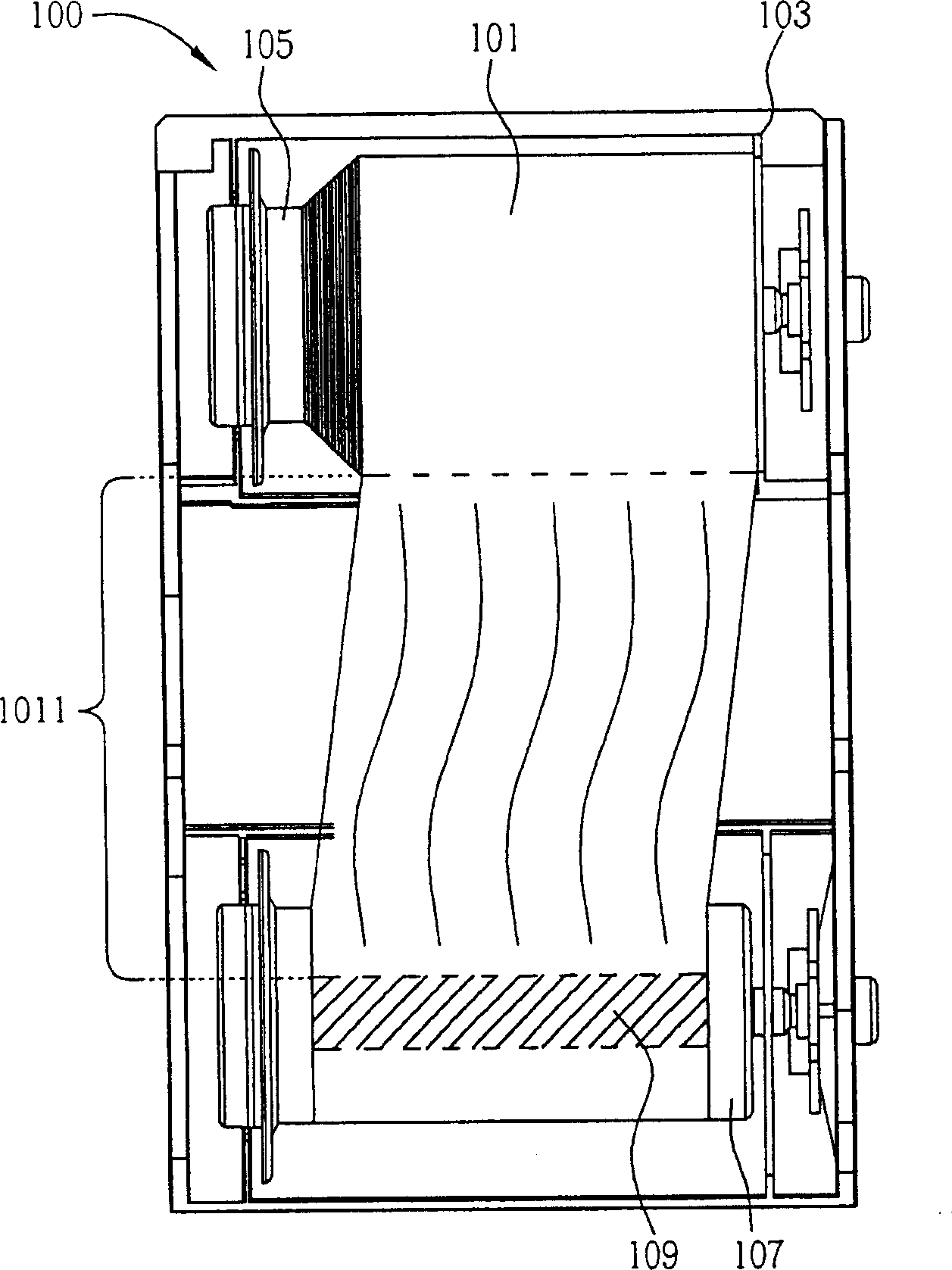

[0017] Figure 5 A partial perspective view of two fixing parts 213 and 215 is configured for the ribbon conveying device 200 of the present invention, wherein a ribbon 201 is wound on the first rotating shaft 205 of the ribbon conveying device 200 . The ribbon transmission device 200 of the present invention includes a ribbon cassette 203, a first rotating shaft 205, and a second rotating shaft 207 ( Figure 5 not shown), a detachable first fixing part 213, and a detachable second fixing part 215. Please note that in order to clearly illustrate the positions where the two fixing members 213 and 215 are installed on the ribbon conveying device 200, Figure 5 Only a part of the color belt transmission device 200 is shown, and the two fixing parts 213 and 215 are as Figure 5 As shown, it is mounted on the ribbon conveying device 200 in a penetrating manner. The detailed structure of ribbon transfer device 200 of the present invention will be Figure 6 are detailed in the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com