Light conducting device, manufacturing and operating method

A technology of a light guide device and a manufacturing method, which is applied in the direction of optical waveguide light guide, light guide, optics, etc., and can solve the problems that it is not easy to reduce the size of the light guide device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

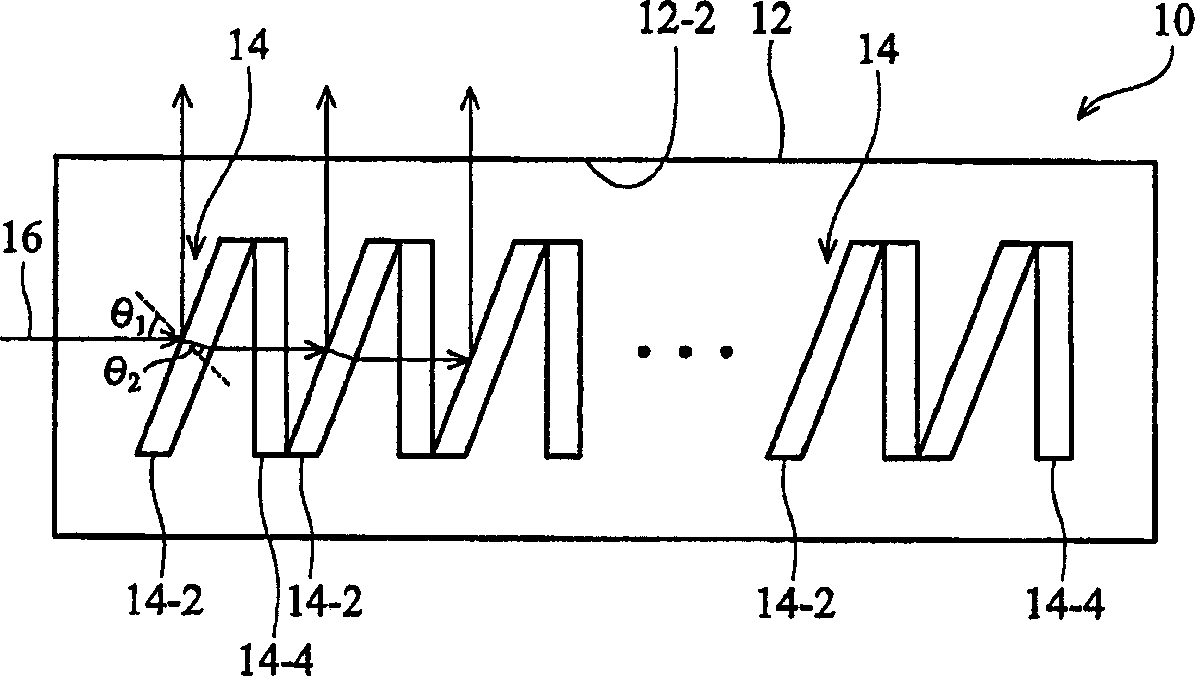

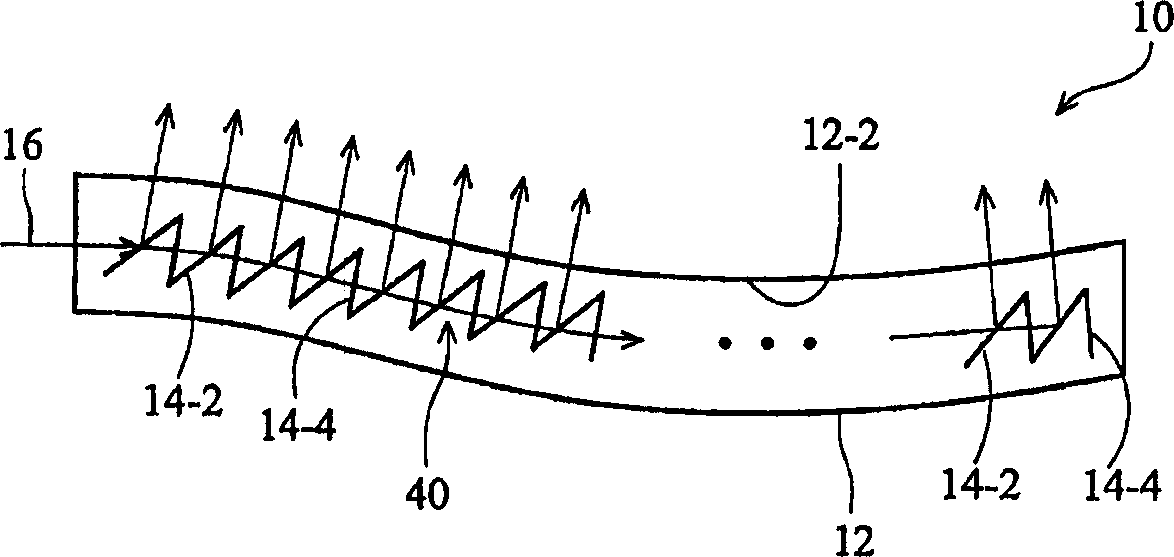

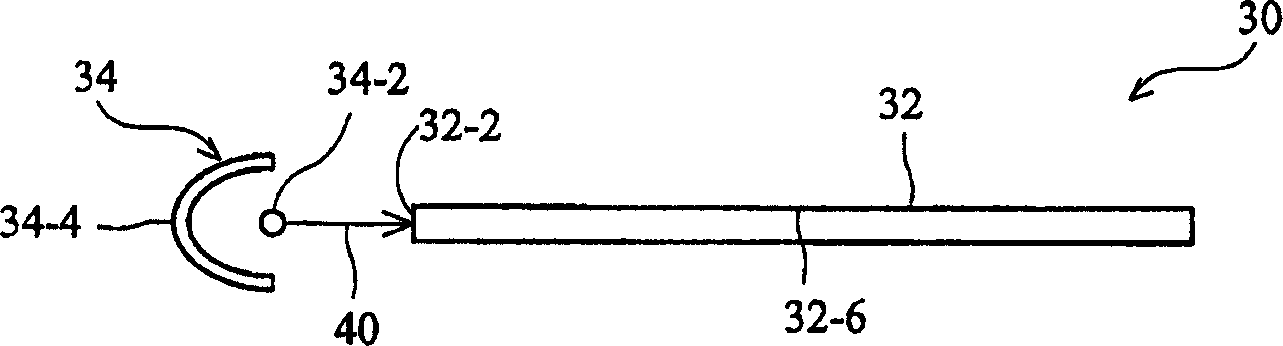

[0040] figure 1 It is a schematic diagram of a light guide device 10 according to an embodiment of the present invention. The light guide 10 includes a first thin film 12 having a first index of refraction and a second thin film 14 having a second index of refraction different from the first index of refraction. The first film 12 and the second film 14 are transparent optical films. According to an embodiment of the present invention, the materials of the first film 12 and the second film 14 are transparent optical glue. In another embodiment, the first membrane 12 and the second membrane 14 are flexible. The first film 12 includes a surface 12-2 serving as a light emitting surface and an accommodating portion disposed therein. The second film 14 is disposed on the first film 12 in a wave form, and includes a plurality of mutually parallel first segments 14-2 and a plurality of mutually parallel second segments 14-4. These first segments 14- 2 and the second segment 14 - 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com