Apparatus and method for manufacturing an absorbent core

An absorbent core and equipment technology, applied in the field of manufacturing absorbent cores, can solve the problems of blocking ventilation devices and sucking out of the core, etc., and achieves the effects of reducing air flow, reducing losses, and reducing the shutdown of cleaning machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Several embodiments of the invention will be presented below with the support of the included figures.

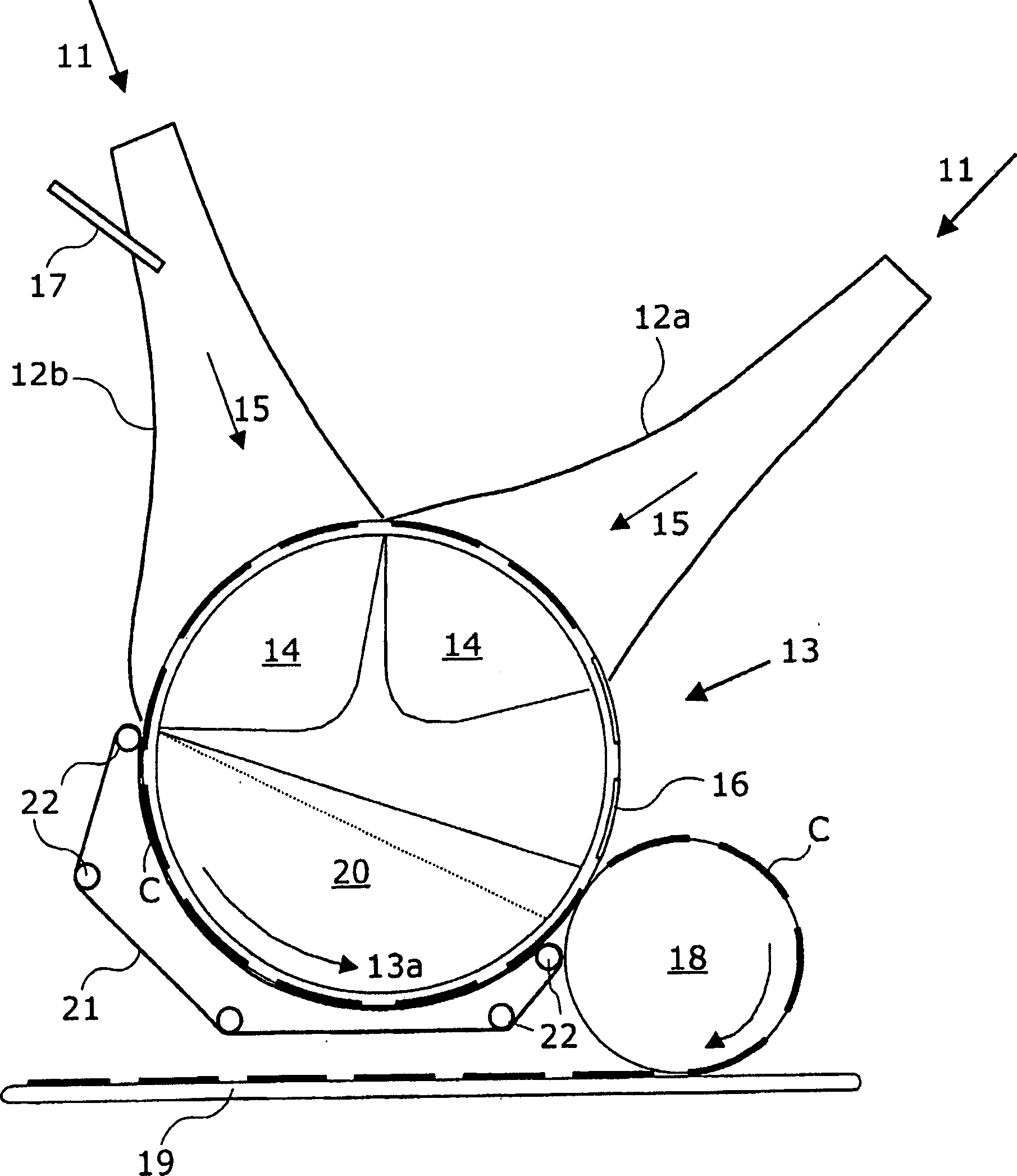

[0034] exist figure 2 In, there is disclosed an apparatus for manufacturing an absorbent core for a liquid-absorbent product according to aspects of the present invention. From a defibration unit (not shown), the pulp fibers 11 are conveyed by means of air flow into forming chambers 12a, 12b here called air ducts. A forming wheel 13 for forming the core of an absorbent product is arranged to rotate under the downstream opening of the air ducts 12a, 12b and is in sealing connection with said air ducts. The forming wheel 13 rotates in the direction indicated by the arrow 13a. In the embodiment according to the figure, the device is provided with two air ducts 12a, 12b. Facing each duct opening, a non-rotating first suction box 14 is arranged inside the forming wheel 13 . Breathing means are arranged along the circumference of the forming wheel 13 to allow air from...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap