Knob of adjusting optical axis of sighting telescope

A technology of optical axis adjustment and scope, applied in the field of scope, can solve problems such as shooting mistakes, outer cover rotation, inconvenient use of firearms, etc., and achieve the effect of improving anti-interference and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Various preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

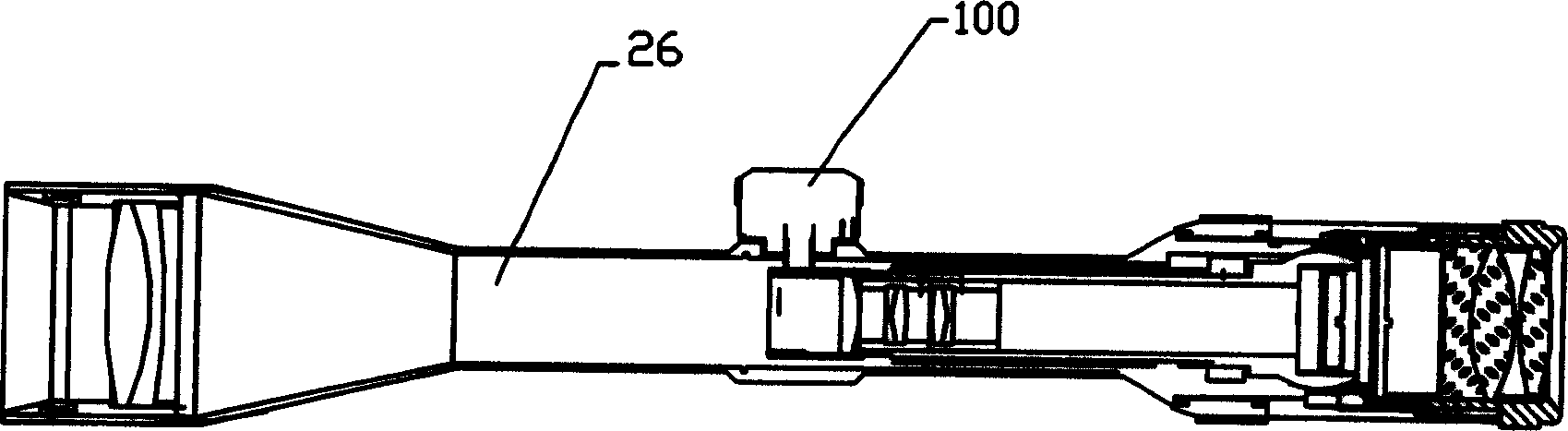

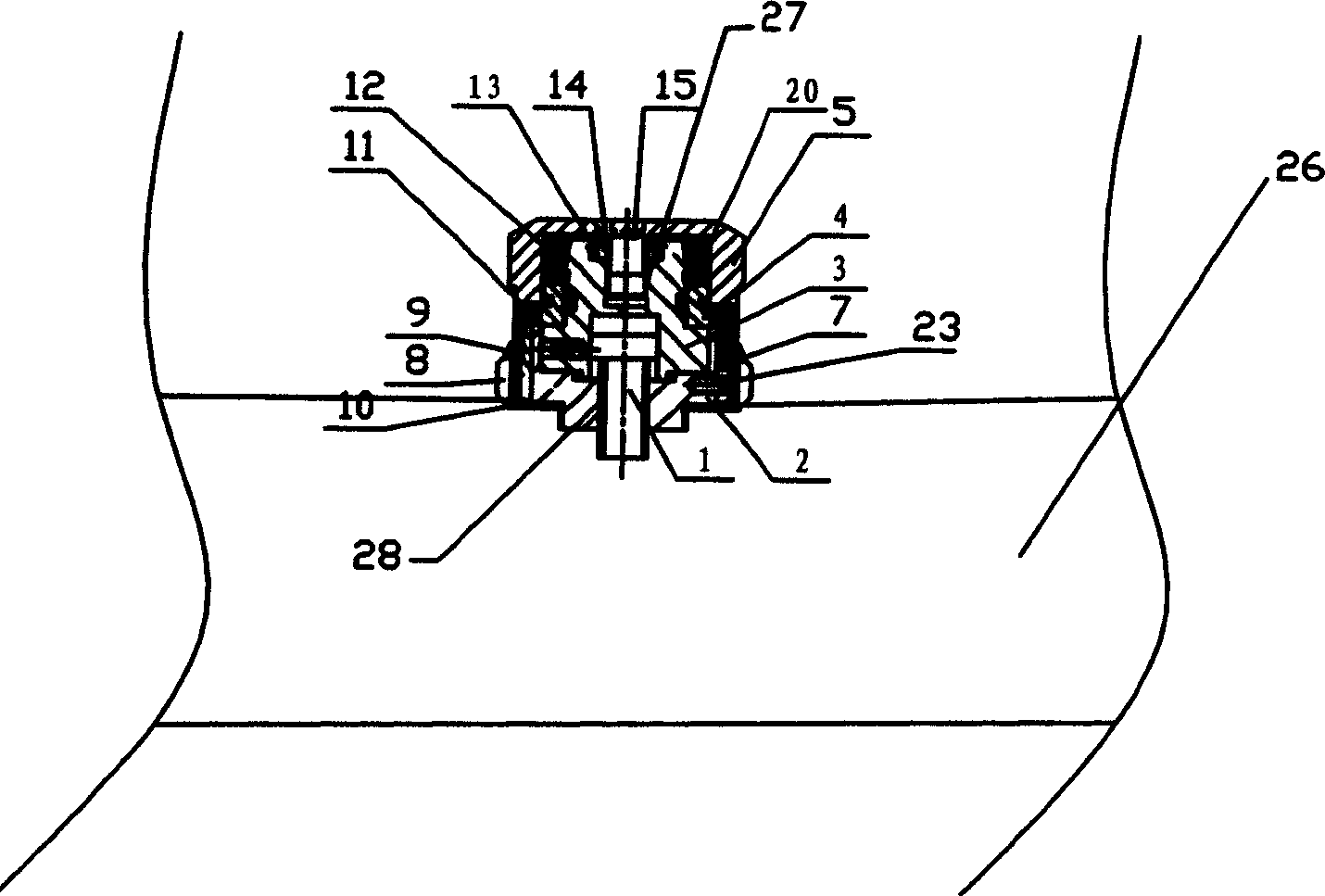

[0020] The optical axis adjustment knob 100 of the scope of the present invention, such as figure 1 As shown, it is arranged on a lens barrel 26 for adjusting the optical axis sleeve in the lens barrel 26, thereby adjusting the optical axis in the lens barrel; as figure 2 As shown, the cross-sectional view of the optical axis adjustment knob of the scope of the present invention shows that the optical axis adjustment knob of the present invention includes an outer cover 5, an adjustment seat 3, a hand wheel seat 2 and an adjustment screw 1, the The hand wheel seat 2 is fixed on the scope barrel 26, and the hand wheel seat 2 is provided with a threaded perforation 28; the lower end of the adjusting screw 1 is a threaded part, which is suitable for the thread in the perforation 28 Matching; the handwheel seat 2 is set as the adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com