Wire rod feeding device

A technology for conveying devices and wire rods, applied in the direction of operating devices, forging/pressing/hammer devices, metal processing equipment, etc., can solve the problems of small force, inconvenience, small contact area, etc., and achieve the effect of fast and stable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

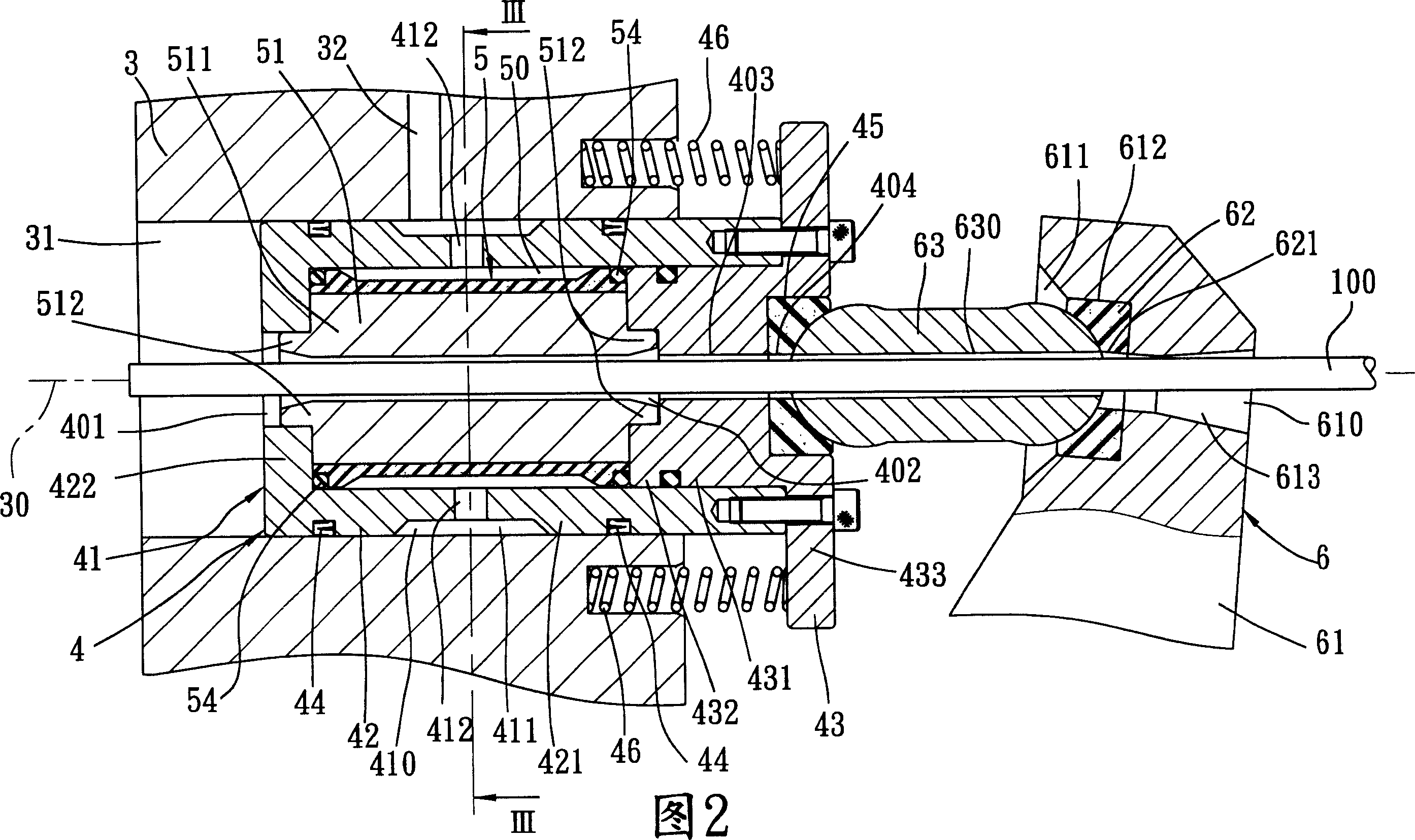

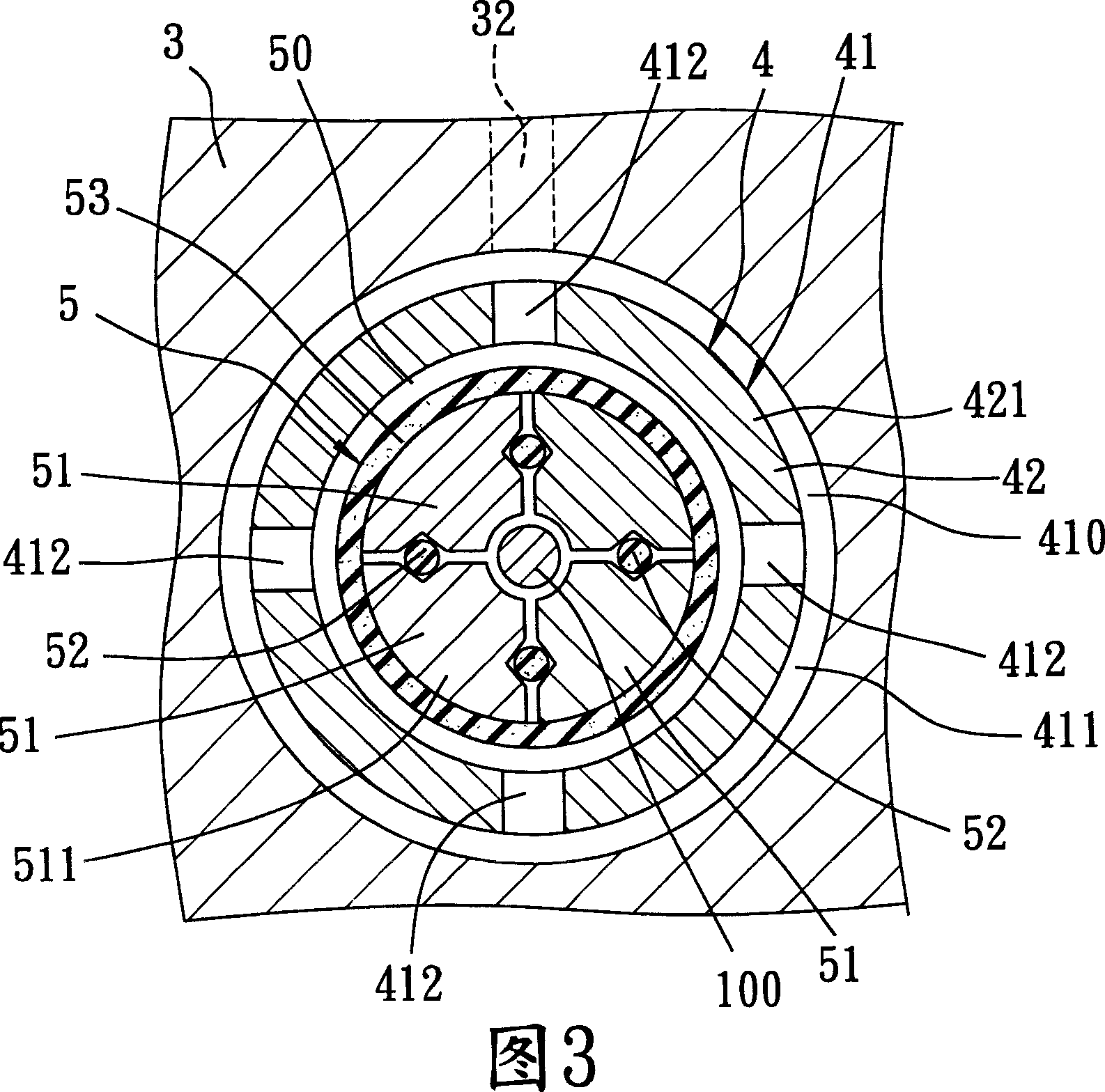

[0013] As shown in Figures 2 and 3, the embodiment of the wire conveying device of the present invention can be used to convey a long wire 100, including a base 3, a wire clip assembly unit 4 assembled on the base 3 and a wire clip Unit 5, and a pushing unit 6 assembled on the right side of base 3 and combined with clamp assembly unit 4.

[0014] The base 3 has an assembly hole 31 extending left and right along an axis 30 , and a flow guide hole 32 extending up and down and communicating with the assembly hole 31 through its bottom end for injecting high-pressure fluid (not shown). In this embodiment, the high-pressure fluid may be liquid or gas.

[0015] The clamp assembly unit 4 includes a moving mechanism 41 airtightly inserted in the assembly hole 31 and having a dispensing hole 410 communicated with the flow guide hole 32, and two upper and lower parts assembled on the right side of the base 3 at intervals. and the elastic reset member 46 between the moving mechanism 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com