Working method of liquid dosing device and liquid dosing device

A working method and liquid technology, applied in the direction of mechanical equipment, gas/liquid distribution and storage, pipeline system, etc., can solve problems such as splashing, slow flow of liquid seasoning, easily damaged gas source devices, etc., to improve life and reliability High performance, improved precision and accuracy, and less residual liquid on the pipe wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

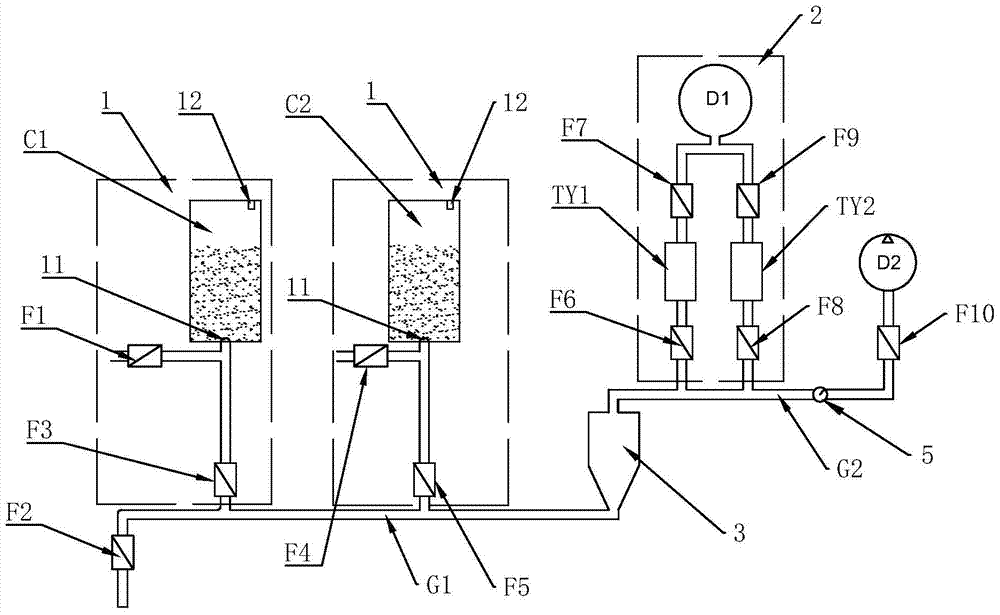

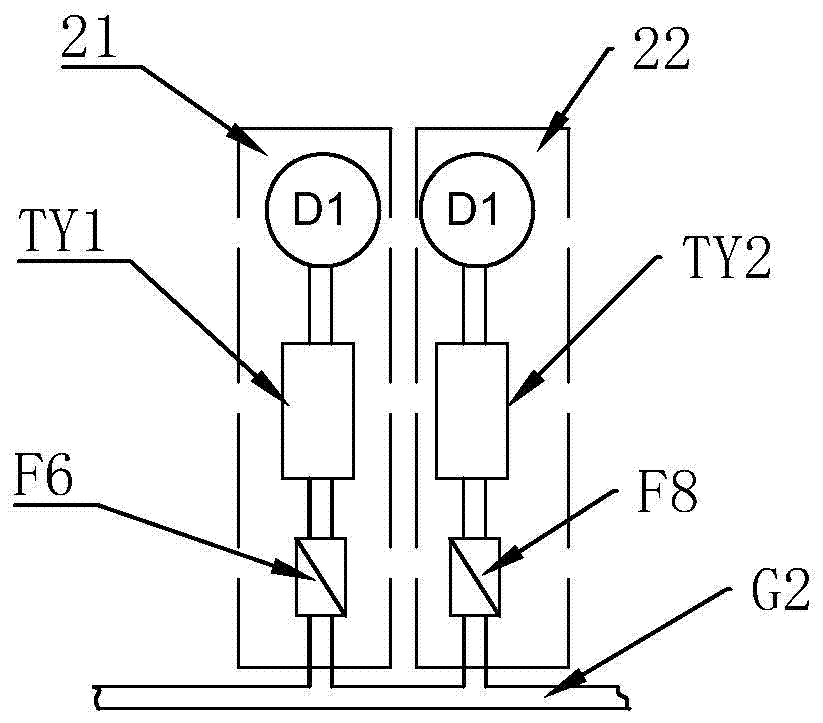

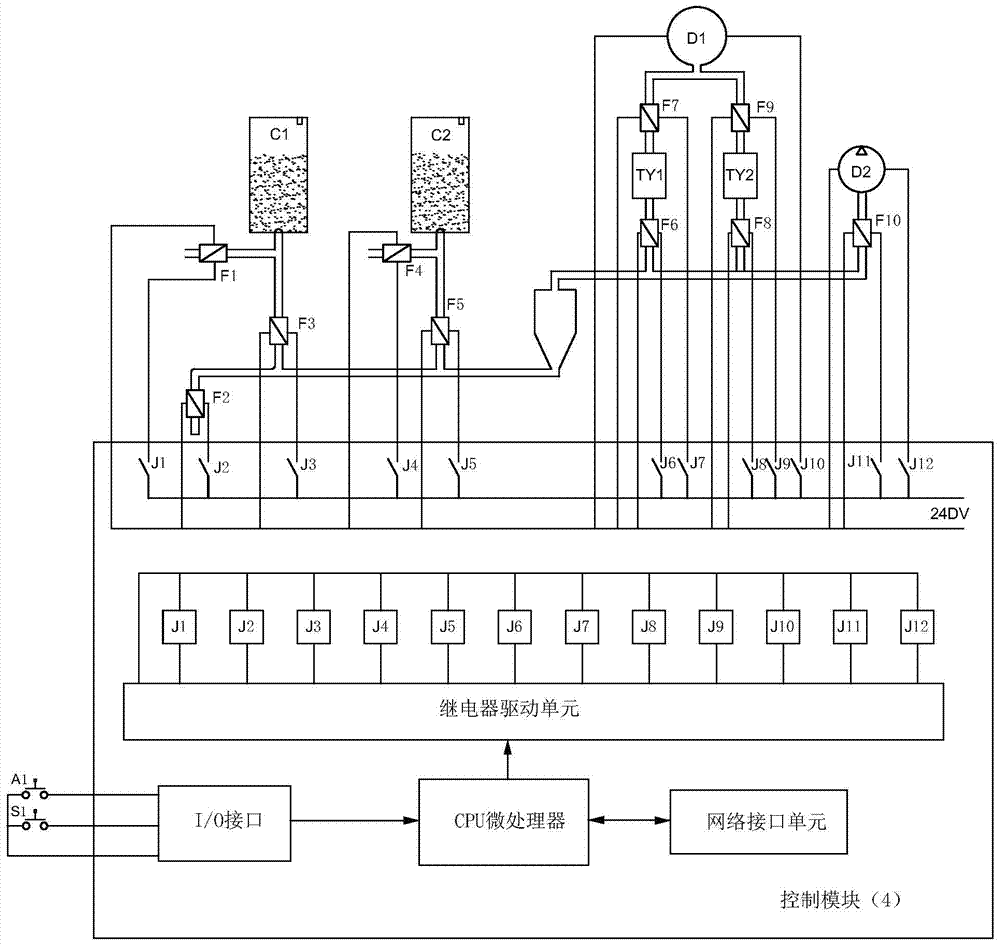

[0038] The liquid measuring device of the present invention includes a liquid storage module 1, a pressure regulating module 2, a buffer module 3 and a control module 4,

[0039] like figure 1 As shown, there can be multiple liquid storage modules 1 in the present invention, which are respectively used to store different types of liquids, such as cooking oil, soy sauce, vinegar and the like. Each liquid storage module 1 is mainly composed of liquid storage units C1~Cn, figure 1 Only C1 and C2 are shown in the figure, and the upper part of each liquid storage unit (such as C1, C2) is provided with an air guide port 12 that can communicate with the atmosphere, so that the liquid in the liquid storage unit (such as C1, C2) can be released u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com